Nano powder-organic polymer composite flocculating agent

An organic polymer, composite flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of large dosage, increased treatment cost, and large amount of sludge generated, so as to reduce the turbidity of effluent and easy to operate. , the effect of reducing the volume of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

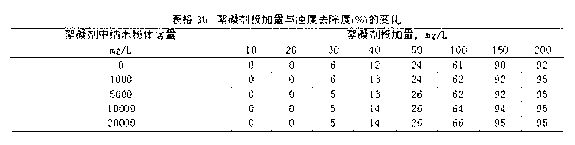

[0020] Preparation: When equipped with PolyDADMAC (polydimethyldiallylamine chloride) stock solution, add 0 mg / L, 1000 mg / L, 5000 mg / L, 10000 mg / L, 20000 mg / L of silica ( SiO2) nano-powders are stirred and polymerized under suitable conditions.

[0021] Application: The oily sewage water sample contains 2000mg / L oil. Take oily sewage and add it to a series of 125mL beakers. Each bottle contains 100mL sewage. The PolyDADMAC flocculant, the flocculant dosage is 5 mg / L, 10 mg / L, 20 mg / L, 30 mg / L, 40 mg / L, 50 mg / L. After the flocculant is added, the fast mixing lasts for 30 seconds; then the slow mixing lasts for 10 minutes. After 15 minutes of static precipitation, the clear liquid was taken for detection, and the oil content and turbidity changes of the water samples before and after treatment were measured. The results show that the removal rate of oil and turbidity reaches 99% and 95% at the optimum dosage.

[0022]

[0023]

[0024]

Embodiment 2

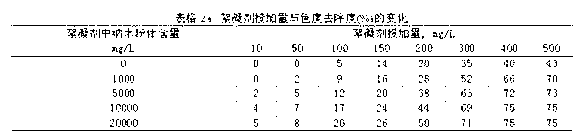

[0026] Preparation: When equipped with PolyDADMAC (polydimethyldiallylamine chloride) stock solution, add alumina (Al2O3 ) Nanopowders are stirred and polymerized under suitable conditions.

[0027] Application: Take high-color sewage water samples and add them to a series of 125mL beakers. PolyDADMAC flocculant of alumina nano powder, the dosage of flocculant is 10 mg / L, 50 mg / L, 100 mg / L, 150 mg / L, 200 mg / L, 300 mg / L, 400 mg / L , 500 mg / L. After the flocculant is added, the fast mixing lasts for 30 seconds; then the slow mixing lasts for 10 minutes. After 15 minutes of static precipitation, the clear liquid was taken for detection, and the color and turbidity changes of the water samples before and after treatment were measured. The results show that: at the optimal dosage, the chroma removal rate reaches 75%, and the turbidity removal rate reaches 80%.

[0028]

[0029]

[0030]

Embodiment 3

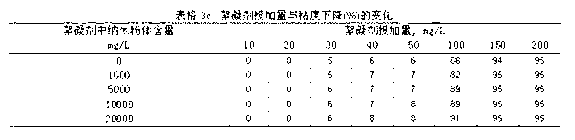

[0032] Preparation: When equipped with PolyDADMAC (polydimethyldiallylamine chloride) stock solution, add iron oxide (Fe2O3 ) Nanopowders are stirred and polymerized under suitable conditions.

[0033] Application: Take oilfield associated water samples and add them to a series of 125mL beakers. PolyDADMAC flocculant of iron oxide nanopowder, flocculant dosage is 10 mg / L, 20 mg / L, 30 mg / L, 40 mg / L, 50 mg / L, 100 mg / L, 150 mg / L , 200 mg / L. After the flocculant is added, the fast mixing lasts for 30 seconds; then the slow mixing lasts for 10 minutes. After 15 minutes of static precipitation, the clear liquid was taken for detection, and the oil content, viscosity and turbidity changes of the water samples before and after treatment were measured. The results show that the oil removal rate reaches 98%, the viscosity decreases by 95%, and the turbidity removal rate reaches 95% at the optimum dosage.

[0034]

[0035]

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com