System and method for supplying motive power for auxiliary machinery of thermal power plant

A technology of supply system and thermal power plant, applied in the direction of machine/engine, steam application, mechanical equipment, etc., can solve the problems of high steam quality requirements of small steam turbines, inability to apply steam in power plants, weak adaptability, etc. The effect of reducing burning and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

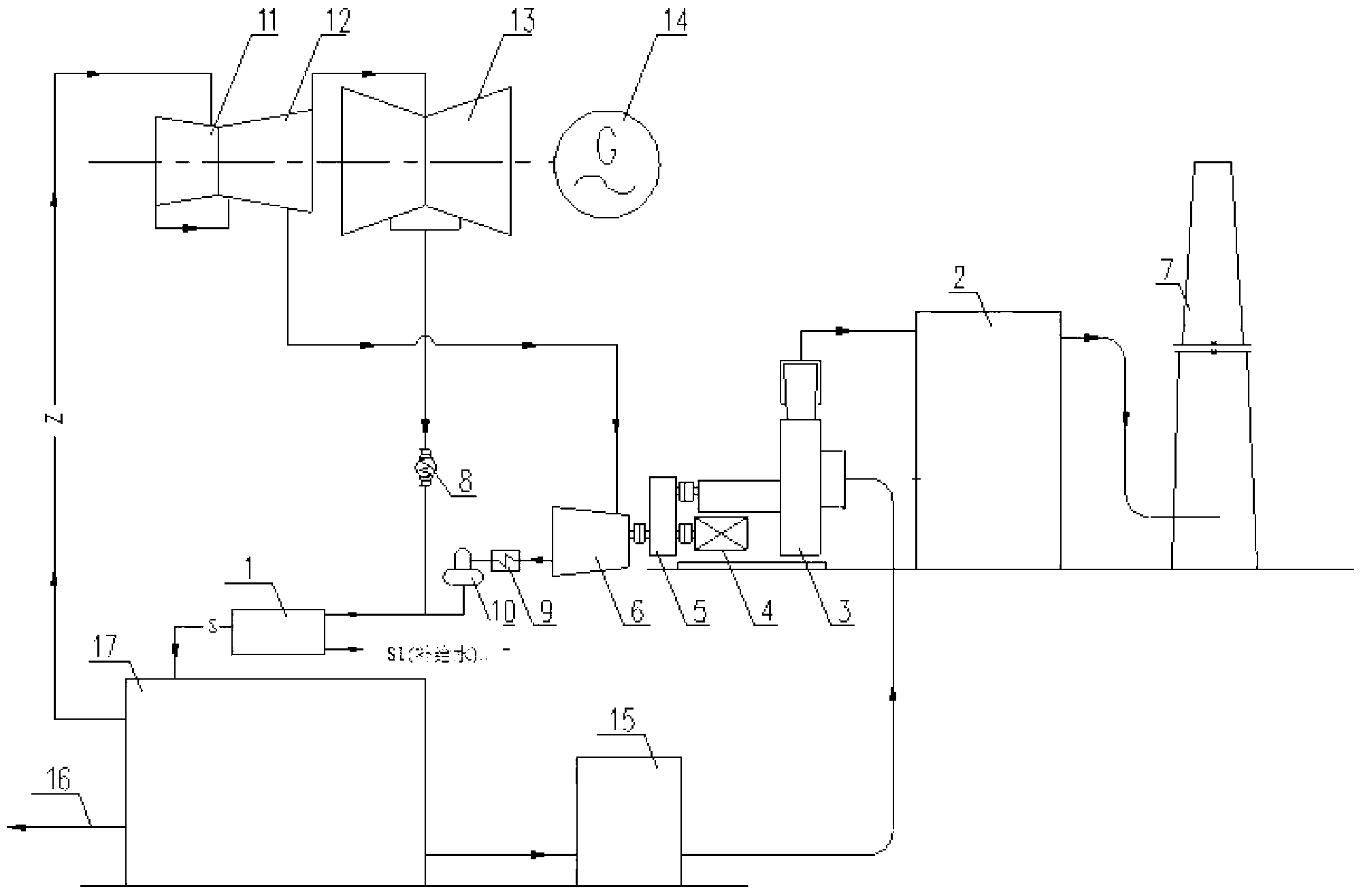

[0016] Attached below figure 1 , the present invention is described in detail.

[0017] Such as figure 1 As shown, the high-temperature and high-pressure steam generated by the heating of the boiler 17 enters the steam turbine, passes through the high-pressure cylinder 11, the medium-pressure cylinder 12, and the low-pressure cylinder 13, and expands step by step to perform work, driving the generator 14 to supply power to the outside, and part of the steam is extracted from the intermediate stage Output as industrial steam extraction. The steam inlet end of the screw expansion power machine is connected to the steam extraction port of the intermediate stage low-grade steam of the steam turbine (or the boiler continuous sewage outlet 16), and the steam drives the screw rotor to rotate, and the speed can reach 2000-3000rmp. The other end of the screw expansion power machine 6 is connected to the reducer 5, and the reducer 5 drives the fans (induced fan 3, desulfurization boos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap