Method for preparing working electrode of scanning electrochemical microscope

A scanning electrochemistry, working electrode technology, applied in scanning probe microscopy, scanning probe technology, measurement devices, etc., can solve the problem of not disclosing working electrodes, increasing the difficulty and cost of working electrodes, scanning electrochemical microscopy Difficulties and other problems, to achieve the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

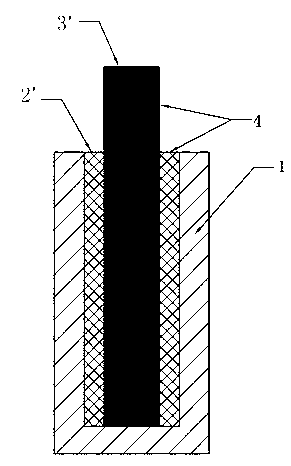

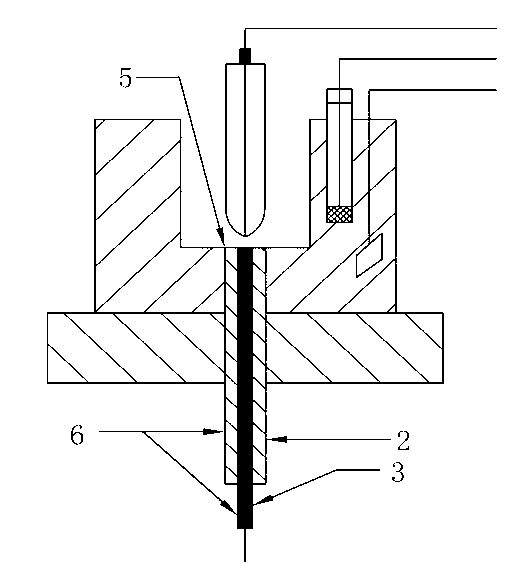

[0013] As shown in the attached figure, 1 is the wax mold, 2 is the epoxy resin, 3 is the sample to be tested, 4 is the working electrode (composed of the sample to be tested 3′ and epoxy resin 2′), and 5 is the small circle Hole 6 is the standard working electrode.

[0014] According to the outer diameter and length of the standard working electrode 6 (composed of the sample 3 to be tested and the surrounding epoxy resin 2) of the scanning electrochemical microscope provided by the manufacturer, use paraffin to cast a hollow whose inner diameter is equal to the outer diameter of the standard working electrode 6 Cylinder (hereinafter referred to as wax mold 1); if the sample 3' to be tested is elongated or cylindrical, directly put the sample 3' to be tested inside the wax mold 1 and ensure that the sample 3' to be tested is If it is not in contact with the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com