Electronic device applied in EUV (Extreme Ultraviolet) vacuum environment

A technology of vacuum environment and electronics, applied in the field of semiconductors, can solve problems such as pollution of electronic devices, and achieve the effect of achieving effective work, improving overall work performance, and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

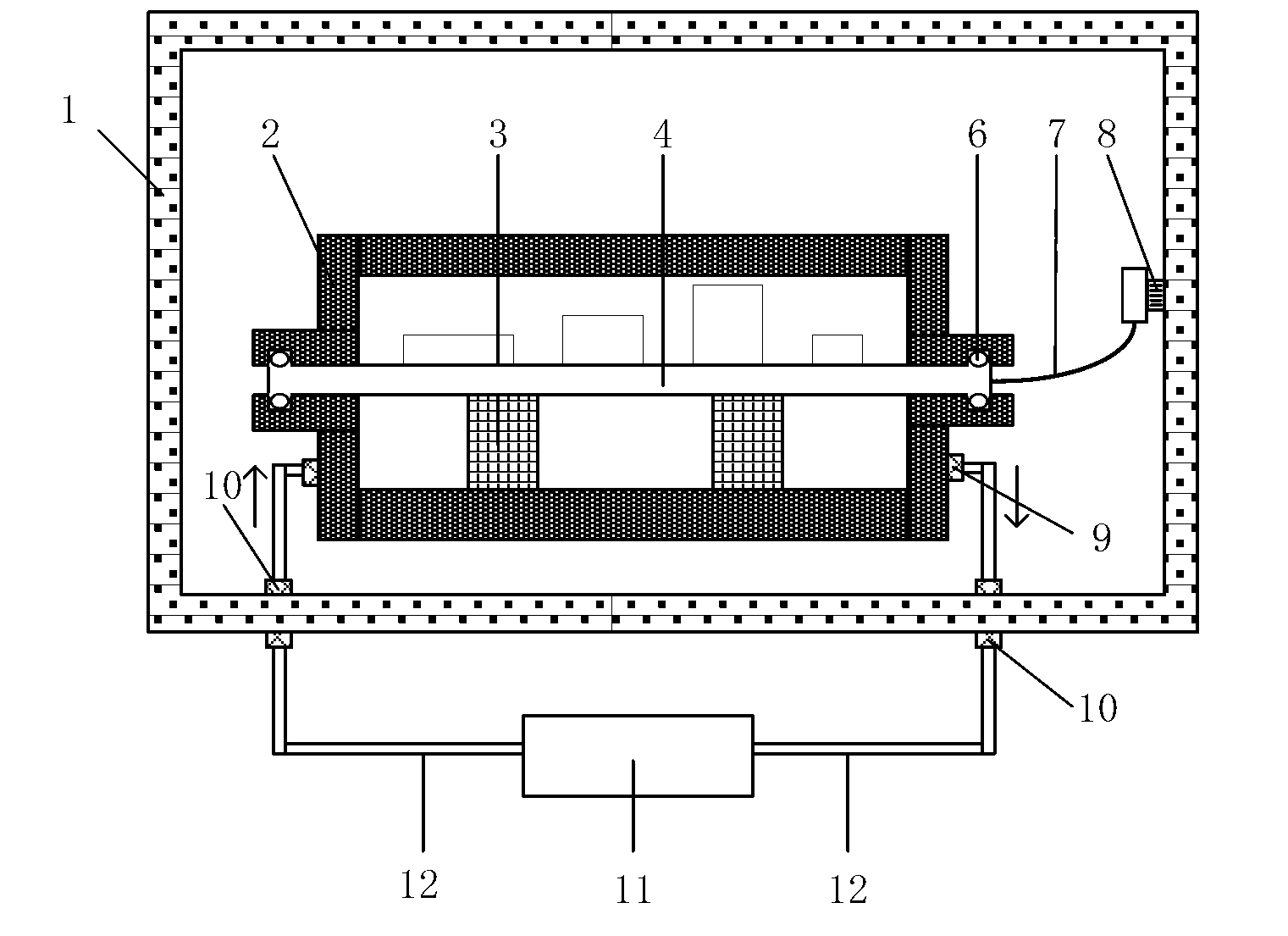

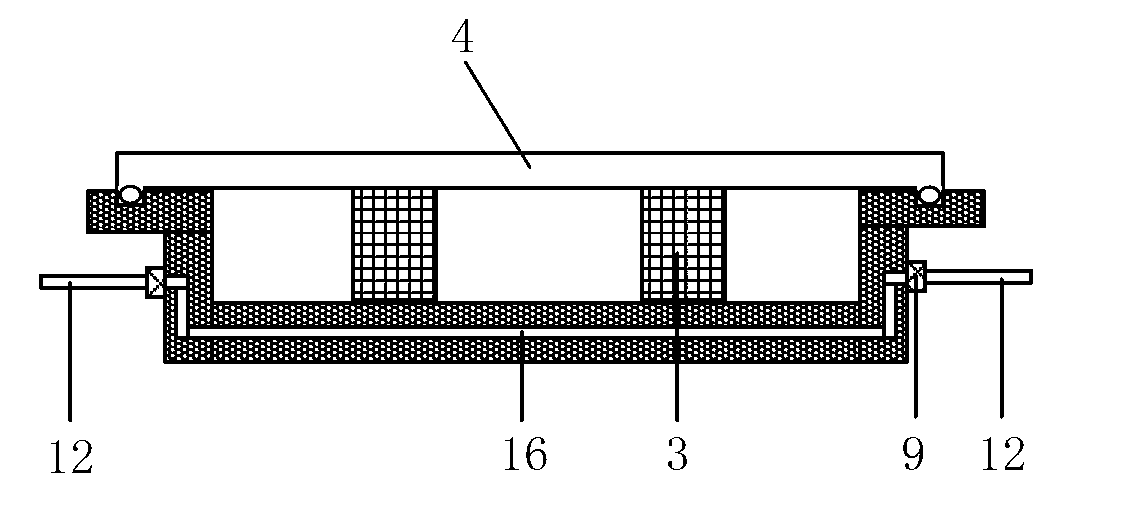

[0046] [Example 1] The embodiment of the liquid temperature control method is as follows image 3 Shown:

[0047] The temperature control liquid enters the second temperature control pipeline 16 in the sealed casing 2 through the first temperature control pipeline 12, and there is a first temperature control connector 9 between the first temperature control pipeline 12 and the second temperature control pipeline 16, so that the sealing Shell 2 maintains a lower temperature. The heat conduction element 3 transfers the heat of the electronic system 4 to the sealed casing 2, and the temperature control fluid takes the heat away from the sealed casing 2 and brings it to the power temperature control device 11 for processing, thereby achieving the control of the electronic system 4. effect of effective heat dissipation.

Embodiment 2

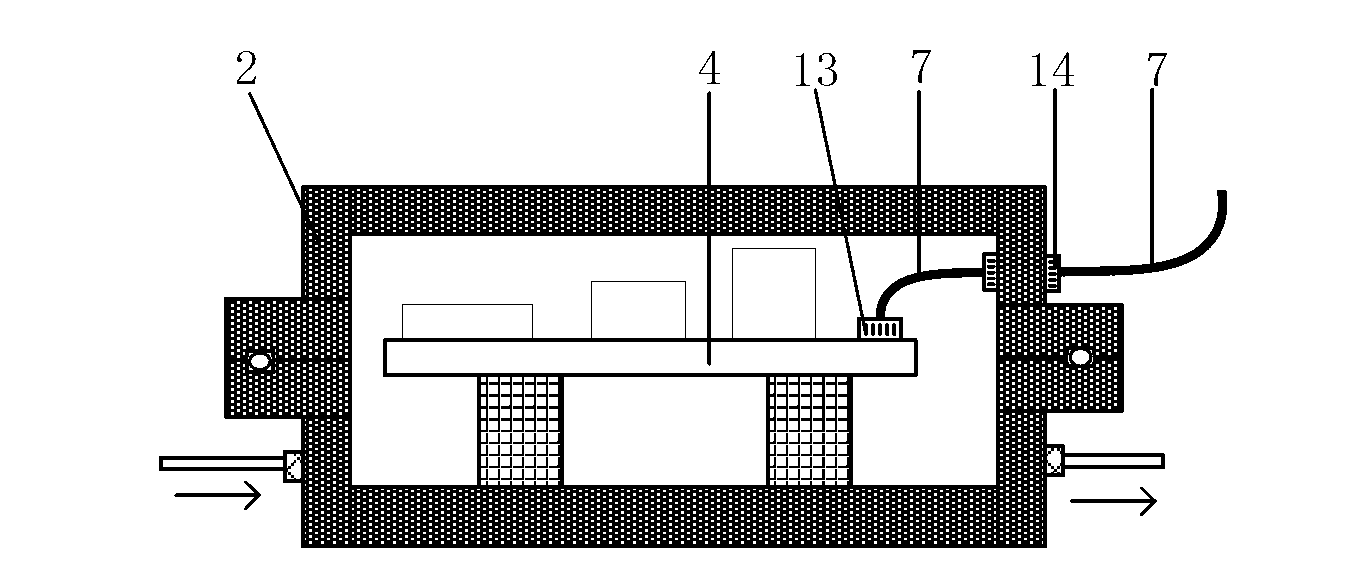

[0048] [Example 2] The embodiment of the gaseous temperature control method is as follows Figure 4 Shown:

[0049] The temperature-controlled gas enters the sealed housing 2 through the second cooling pipeline 16 in the sealed housing 2, and there is a first temperature-controlled connector 9 between the first temperature-controlled pipeline 12 and the second temperature-controlled pipeline 16 of the sealed housing 2 , the first temperature-controlled connector 9 ensures the tightness of the sealed casing 2, the temperature-controlled gas takes away the heat from the surface of the electronic system 4, and at the same time takes away the pollutants in the sealed casing 2, and the temperature-controlled gas enters the Processing is performed in the power temperature control device 11 to clean the temperature-controlled gas, and at the same time further cool / heat the temperature-controlled gas, so as to effectively control the temperature of the electronic system 4 . That is t...

Embodiment 3

[0050] [Example 3] Examples of solid-state temperature control methods Figure 5 Shown:

[0051] This method is adopted when the heat generated by the electronic system 4 is not large. The heat conduction member 3 is made of a semiconductor temperature control material, which can absorb the heat generated by the electronic system 4 and transfer it to the sealed casing 4 connected to it, so as to achieve The electronic system 4 performs effective temperature control.

[0052] For the embodiment of the present invention, the sealed casing 2, the heat conducting element 3, and the connecting element are all made of low outgassing materials.

[0053] The above-mentioned technical solutions in the embodiments of the present application have at least the following technical effects or advantages:

[0054] An electronic device used in an EUV vacuum environment provided by an embodiment of the present invention puts the electronic system into a sealed casing so that the pollutants e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com