Hybrid drive device

A driving device and hybrid technology, which is applied in the direction of power devices, hybrid vehicles, pneumatic power devices, etc., can solve problems such as cost increase, second clutch slip control time becomes longer, control device problems, etc., to eliminate waste , Improve fuel utilization performance and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

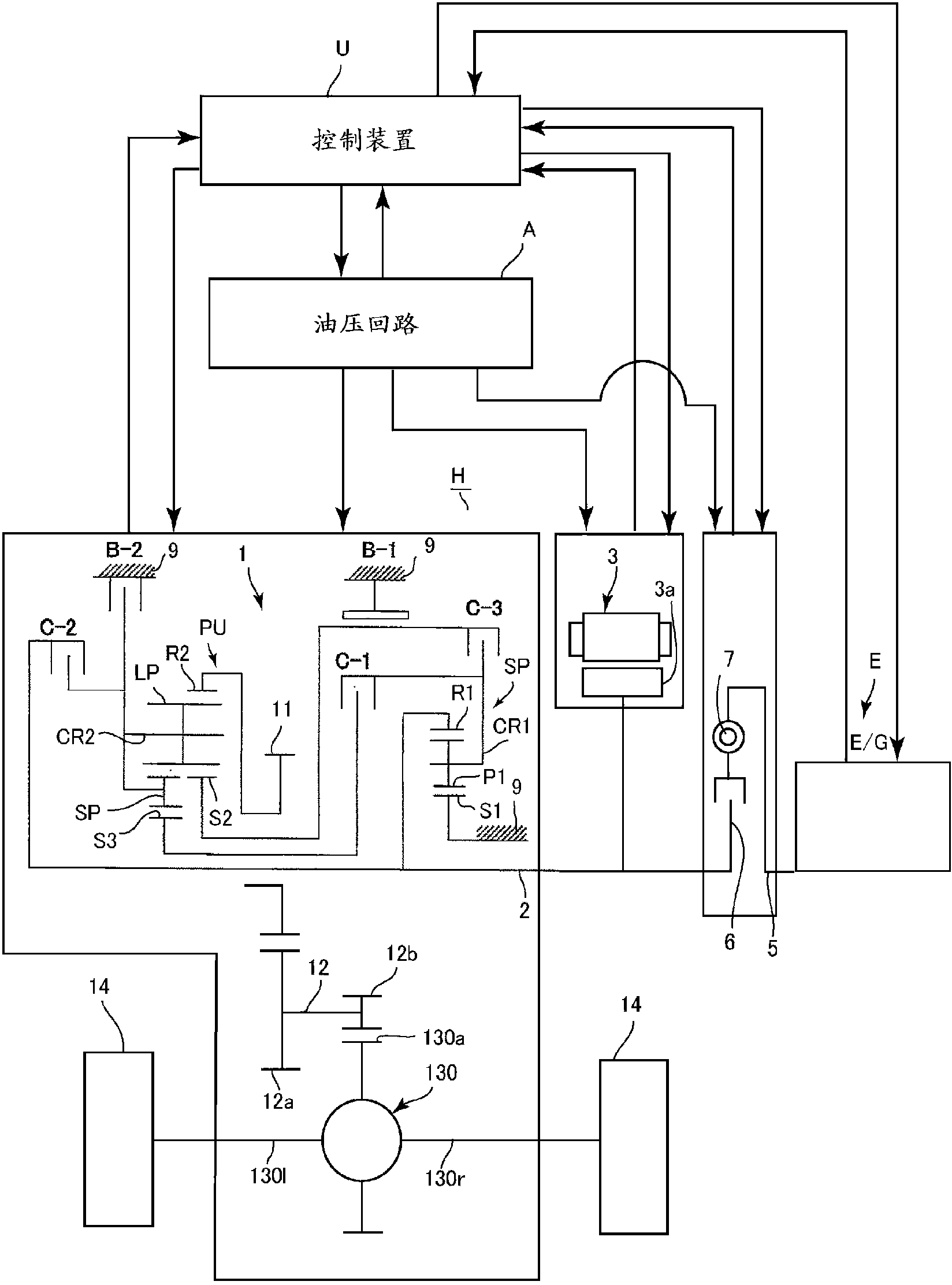

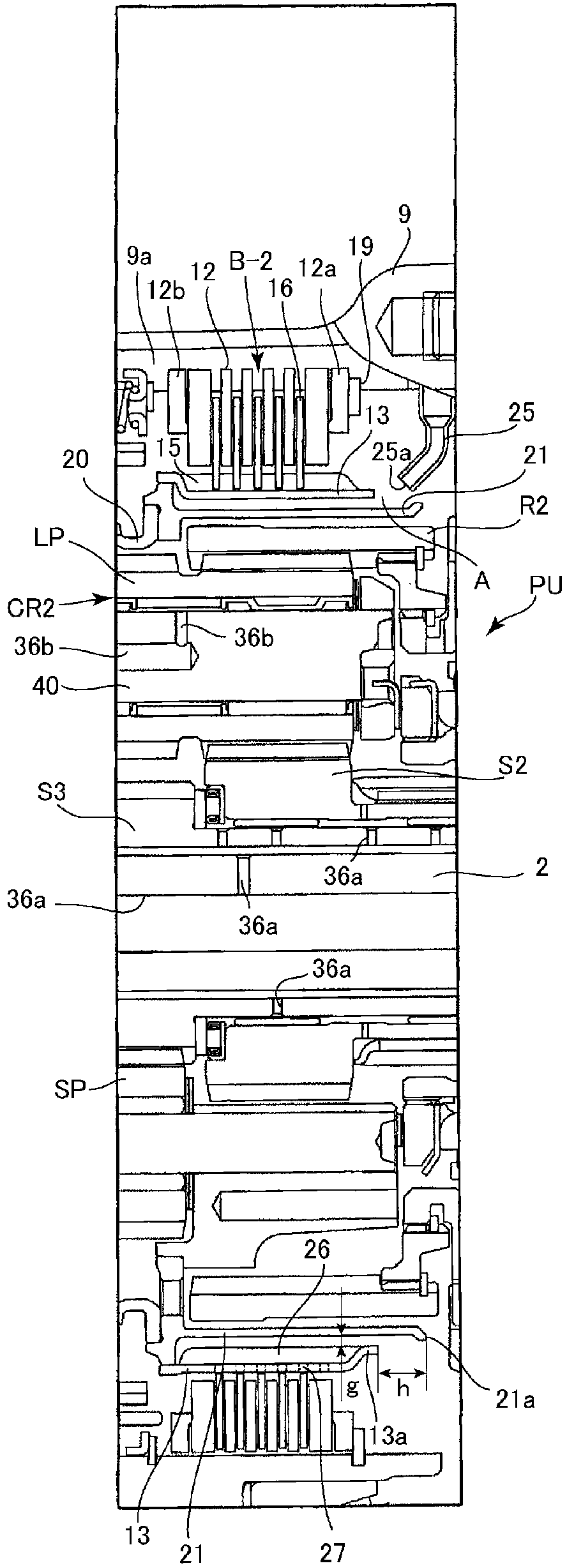

[0031] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, the rotor 3a of the electric motor 3 is connected to the input part 2 (hereinafter referred to as the input shaft 2) of the automatic transmission 1, and the clutch 6 and the torsional vibration damper are interposed between the input shaft 2 and the engine output shaft 5 (torsion damper) 7. Therefore, this automatic transmission 1 is applied as a single-motor parallel type hybrid drive device H, and the above-mentioned electric motor 3 functions as a vehicle driving source and also as a starter (self starting motor) for starting an engine. It functions as an alternator (generator) that converts engine power or the inertial force of the vehicle into electrical energy. In addition, although the above-mentioned clutch 6 and torsional vibration damper 7 are arranged between the input shaft 2 and the engine output shaft 5, a torque converter (torque con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com