Bone wall separation process

A bone wall and process technology, applied in the field of bone wall separation technology, can solve the problems of making the best use of materials, waste of resources, and no bone wall separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0015] Specific Embodiment 1: This embodiment provides a bone wall separator and a method for separating a bone wall using the same.

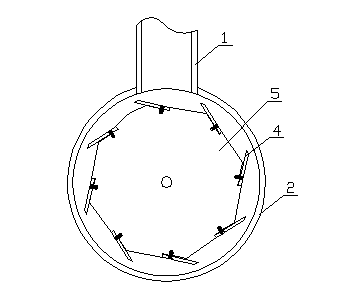

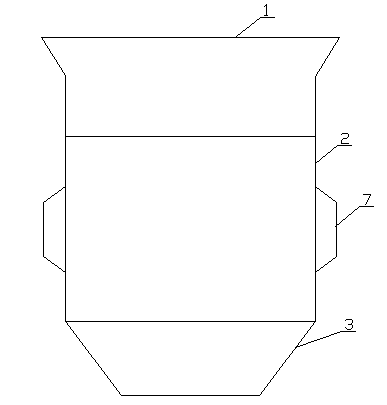

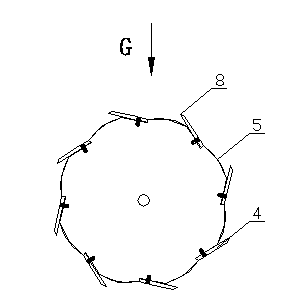

[0016] One, such as Figure 1-5 As shown, the device for separating the inner wall and the outer wall of bone by extrusion and grinding according to the present invention includes a feeding hopper 1 , a stripping chamber 2 and a discharge port 3 from top to bottom. The feeding hopper 1, the stripping bin 2, and the discharge port 3 are connected. A rotary stripping assembly is installed in the stripping chamber 2, and the rotary stripping assembly is composed of 6-12 blades 4 and a rotating shaft 5. The axis of the rotating shaft 5 is located on the transverse centerline of the stripping chamber 3; the axial surface of the rotating shaft 5 is along the circumferential direction A number of inclined blades 4 are evenly arranged and their cutting edges 8 are exposed outwards. The cutting edges 8 are adjustable by 2-10mm higher than the rotating ...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that this embodiment provides a bone wall separation process after slaughtering and dividing fresh bones to extract bone collagen liquid, and the specific steps are as follows:

[0029] (1) Extraction of bone collagen solution:

[0030] (1) After soaking, rinsing, cutting into pieces and freezing the fresh bone, put it into an extraction tank and seal it;

[0031] (2) Start the vacuum pump, open the valve connected to the buffer tank, make the buffer tank negative pressure, and turn off the vacuum pump when the vacuum degree is 14-75mmhg;

[0032] (3) Open the steam valve in the extraction tank, be warming up to indicate that the temperature is 20-50 ° C, and when the pressure in the tank is 0.01-0.1MPA, close the intake valve;

[0033] (4) Gradually open the valve of the buffer tank connected to the extraction tank, pump the blood melted from the bone into the buffer tank, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com