Heat wave-transmission porous ceramic material and preparation method thereof

A technology of porous ceramics and heat penetration, applied in the field of functional ceramics, which can solve the problems of poor mechanical properties, easy deliquescence, and unsuitable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

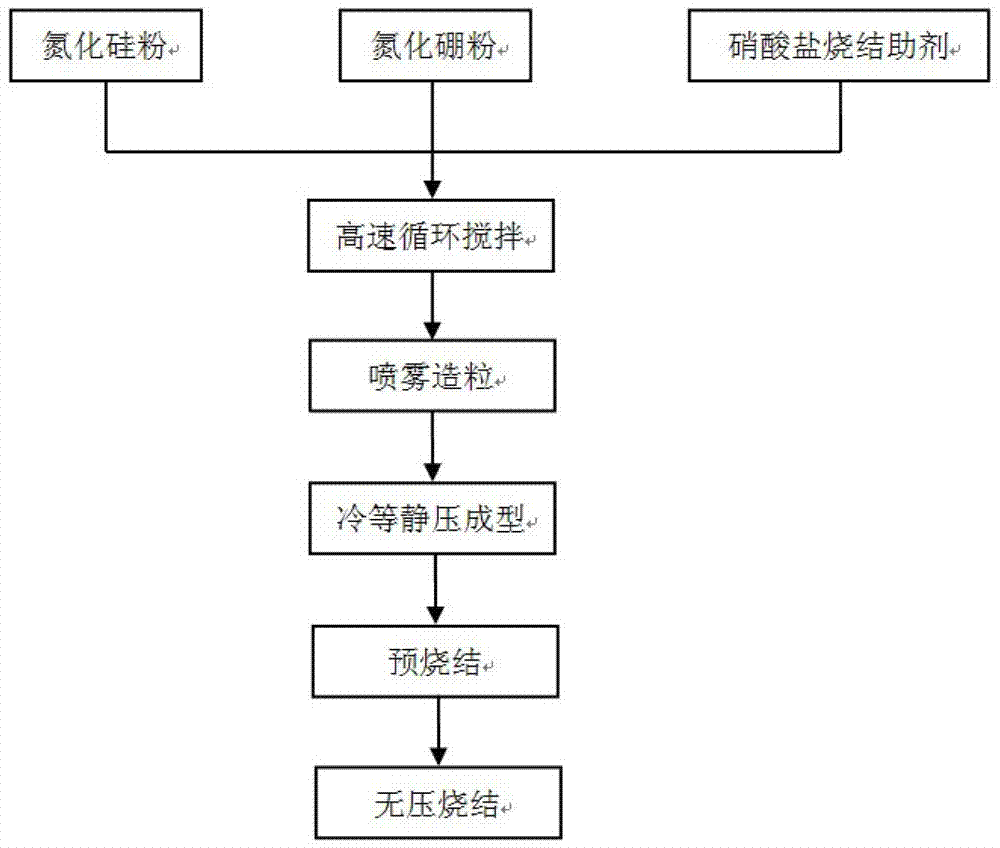

Method used

Image

Examples

Embodiment 1

[0049] Silicon nitride, lanthanum nitrate and boron nitride are prepared into ceramic raw material powder according to the weight ratio of 90:5:5. Use absolute ethanol as a dispersant and silicon nitride balls as grinding balls for the ceramic raw material powder. After 4 hours of high-speed circulation and stirring, spray granulation treatment to obtain a granular powder with an average particle size of 30 μm, which is loaded into a mold for The body was obtained by cold isostatic pressing, and the molding pressure was 80 MPa. Carry out pre-sintering under the air atmosphere with the formed green body, the sintering temperature is 600 ℃, keep warm for 60 minutes, then pass through the pressureless sintering under the nitrogen atmosphere, the sintering temperature is 1650 ℃, keep warm for 1 hour, obtain the thermal Wave-transparent porous ceramic materials.

[0050] The samples have been tested, and the technical indicators are shown in Table 1:

[0051] Table 1 Performance ...

Embodiment 2

[0054] Silicon nitride, cerium nitrate and boron nitride are formulated into ceramic raw material powder according to the weight ratio of 82:8:10. Use absolute ethanol as a dispersant and silicon nitride balls as grinding balls for the ceramic raw material powder. After stirring at a high speed for 5 hours, spray granulation treatment to obtain a granular powder with an average particle size of 25 μm, and put it into a mold for The body was obtained by cold isostatic pressing, and the molding pressure was 70 MPa. Carry out pre-sintering under the air atmosphere with the formed green body, the sintering temperature is 550 ℃, keep warm for 40 minutes, then pass through the pressureless sintering under the nitrogen atmosphere, the sintering temperature is 1700 ℃, keep warm for 1.5 hours, obtain the thermal Wave-transparent porous ceramic materials.

[0055] The samples have been tested, and the technical indicators are shown in Table 2:

[0056] Table 2 Performance test situati...

Embodiment 3

[0059] Silicon nitride, lanthanum nitrate, cerium nitrate and boron nitride are formulated into ceramic raw material powder according to the weight ratio of 78:6:6:10. Use absolute ethanol as a dispersant and silicon nitride balls as grinding balls for the ceramic raw material powder. After stirring at a high speed for 6 hours, spray granulation treatment to obtain a granular powder with an average particle size of 30 μm, and put it into a mold for The body was obtained by cold isostatic pressing, and the molding pressure was 90 MPa. Carry out pre-sintering under the air atmosphere with the molded green body, the sintering temperature is 600 ℃, keep warm for 60min, then pass through the pressureless sintering under the nitrogen atmosphere, the sintering temperature is 1750 ℃, keep warm for 1.5 hours, obtain the thermal Wave-transparent porous ceramic materials.

[0060] The samples have been tested, and the technical indicators are shown in Table 3:

[0061] Table 3 Performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com