Process for producing bone blood peptide microbial organic fertilizer by using animal skeletons and slaughter blood organic wastewater

A technology of microbial organic fertilizer and organic wastewater, applied in the field of bone blood peptide organic fertilizer, can solve the problems of increasing the difficulty and cost of sewage treatment, incomplete discharge indicators, etc., and achieve the effect of increasing added value and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

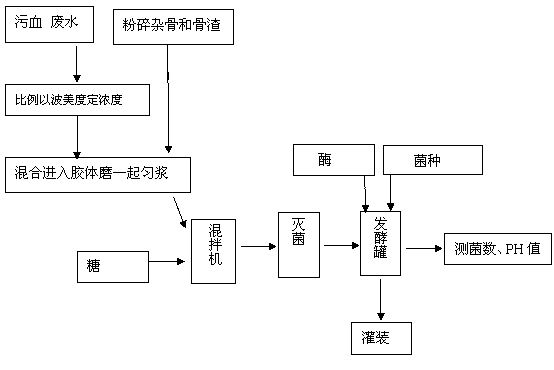

[0022] Specific implementation mode 1: In this implementation mode, the bone blood peptide organic fertilizer is produced by slaughtering and dividing fresh bones and polluted blood organic waste water according to the following steps:

[0023] (1) According to the mass ratio of slaughter blood organic wastewater mixture 85-90, animal bones 10-15, mix with a colloid mill and beat to 160-200 mesh;

[0024] (2) input brown sugar accounting for 5-15% of the total weight of the mixture;

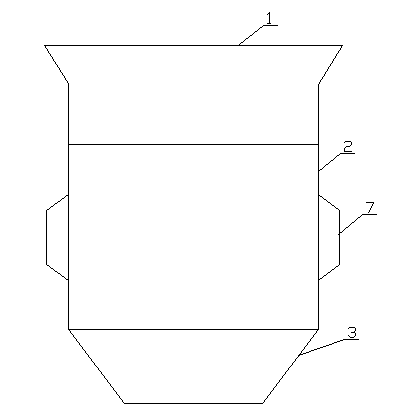

[0025] (3) After stirring for 15-20 minutes, pump it into a tubular sterilizer, carry out sterilization treatment at 90-140°C and a flow rate of 1000-1200L / h, and then pump it into a sterilized frame-type stirring fermenter , open the fermenter jacket valve to pass cold water and stir to cool down;

[0026] (4) When the material cools down to 40-50°C, put in animal proteolytic enzyme and lipase respectively accounting for 0.1-0.5% of the total weight of the material, enzymolyze at 40-50°C for 2-...

specific Embodiment approach 2

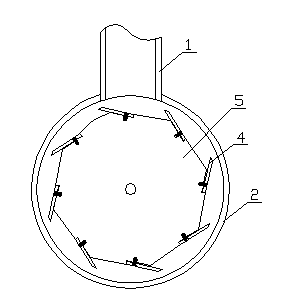

[0045] Specific implementation mode two: as figure 1 As shown, this embodiment utilizes slaughtered and segmented fresh bones and polluted blood organic wastewater to produce bone blood peptide microbial organic fertilizer according to the following steps:

[0046] 1. The blood from slaughtering and smearing blood, the blood and water separated from fresh bones and the blood-containing sewage mixture collected by diversion discharge, according to the mass ratio, 20-30 of red blood, 20-30 of blood and water separated from fresh bones, and 20-30 of blood and sewage collected by diversion discharge The blood and sewage are mixed in a ratio of 40-60, and the standard value is determined according to the degree of Baume to guide the concentration ratio.

[0047] 2. Separation of the inner wall of the bone:

[0048] (1) Extraction of bone collagen solution:

[0049](1) After soaking, rinsing, cutting into pieces and freezing the fresh bone, put it into the extraction tank and seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com