Real stone paint of real stone metal plate and manufacturing process of real stone metal plate

A manufacturing process, a technology of real stone paint, applied in the direction of metal layered products, coatings, layered products, etc., can solve the problems of vegetation and soil damage, high energy consumption, unfavorable ecological environment, etc., to overcome fatal defects and service life. Improve and overcome the effect of water softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The manufacture of the real stone paint and the real stone metal plate of the present invention will be further described below in conjunction with the accompanying drawings and examples.

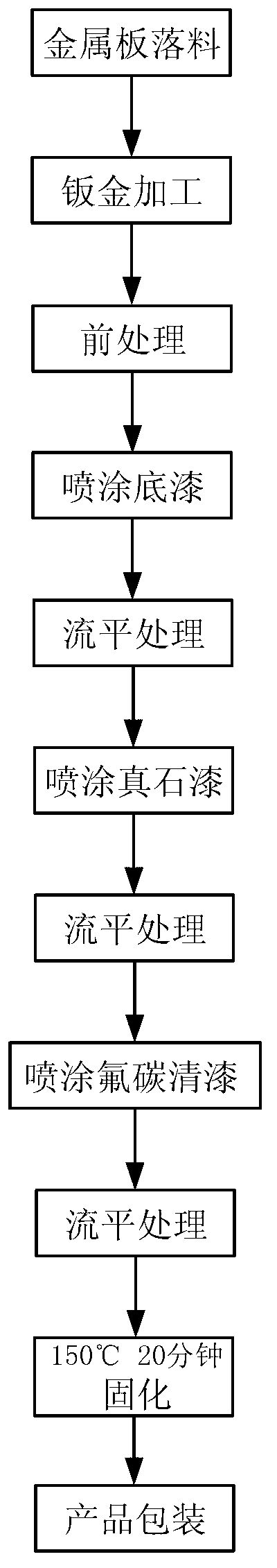

[0040] Such as figure 1 The manufacturing process of real stone metal plate of the present invention is as follows:

[0041] a. Metal sheet metal processing to obtain a metal sheet substrate;

[0042] b. After pretreatment, spray primer, and then leveling treatment;

[0043] Wherein the proportioning by weight of each component of the primer in the primer configuration is as follows:

[0044] Epoxy resin E 51 70 parts

[0045] Epoxy resin 601 30 parts

[0046] Dicyandiamide 10 parts

[0047] 15 parts of liquid nitrile rubber (17 parts, 20 parts can also be prepared)

[0048] 2 parts dibutyl phthalate

[0049] 5 parts of white carbon black (4 or 3 parts can also be prepared);

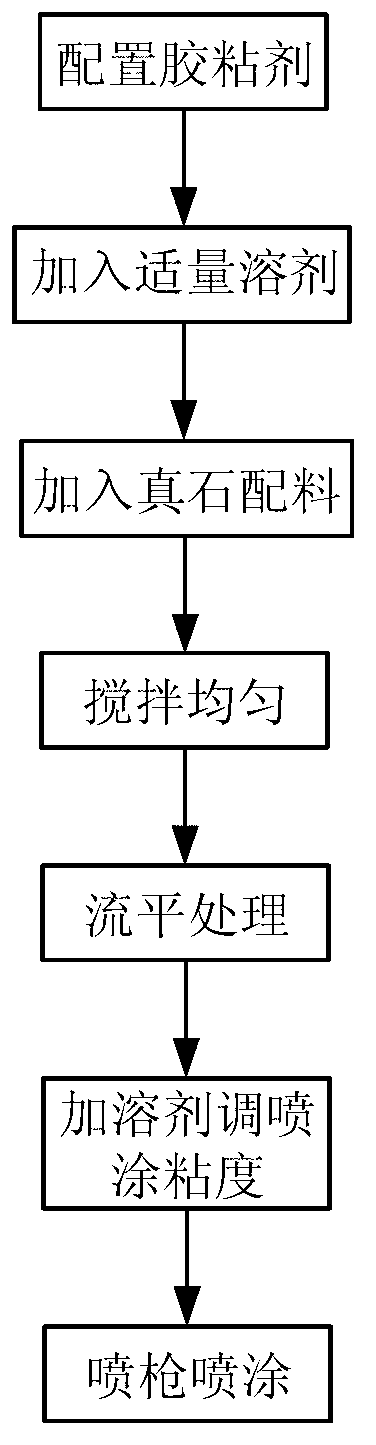

[0050] c. Configure real stone paint, spray real stone paint, and then leveling treatment;

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com