Salty waste water incineration disposal system and disposal method thereof

A technology for salt-containing wastewater and treatment system, applied in combustion methods, incinerators, combustion types, etc., can solve problems such as high combustion costs, lower flue gas temperature, etc., to simplify the process flow, improve the continuity of production, and shorten construction. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

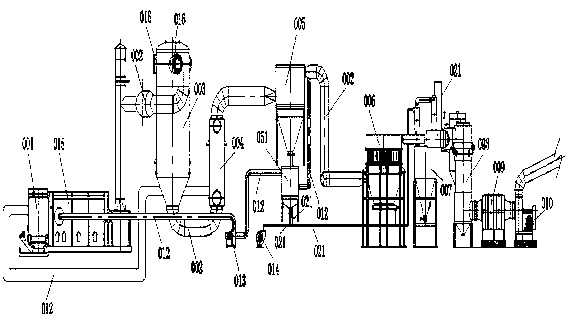

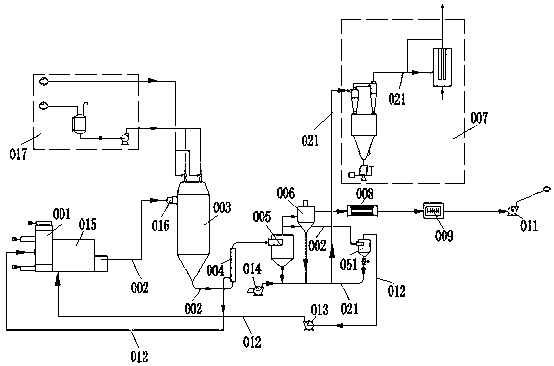

[0023] Example 1: A saline waste water incineration treatment system, including an incinerator 003, a waste water pressurization device 017 that pumps high-pressure atomized waste water into the incinerator, a gas supply device that feeds high-temperature flue gas into the incinerator, and feeds the incinerator Auxiliary combustion equipment that feeds combustion-supporting gas, a cooling device that quenches the product obtained from the reaction in the incinerator, and a dust removal device that purifies the quenched flue gas. The gas supply equipment is coal-burning machine 001, coal-burning machine 001 The generated high-temperature flue gas is connected to the incinerator 003 through the pipeline 002; the cooling device is a radiation radiator 004, and the inlet of the radiation radiator 004 is connected to the smoke exhaust pipeline 002 at the bottom of the incinerator 003, and the outlet pipeline 002 is connected to the dust removal equipment; the dust removal The equipm...

Embodiment 2

[0024] Embodiment 2: Referring to Embodiment 1, a circulating flue gas pipeline 012 is additionally provided on the radiant radiator 004 to communicate with the coal burner 001 .

Embodiment 3

[0025] Embodiment 3: Referring to Embodiment 1 or 2, a circulating flue gas pipeline 012 is provided on the pipeline between the flue gas outlet of the multi-pipe dust collector 005 and the flue gas inlet of the Taimian high-temperature dust collector 006 to communicate with the coal burner 001.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com