Closed type chromatography test paper detection device and application method of closed type chromatography test paper detection device

A chromatography test paper and detection device technology, which is applied in the direction of measuring devices, chemical instruments and methods, and analytical materials, can solve the problems of cumbersome operation, inability to detect multiple reaction solutions, and increased difficulty and cost of injection molding production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

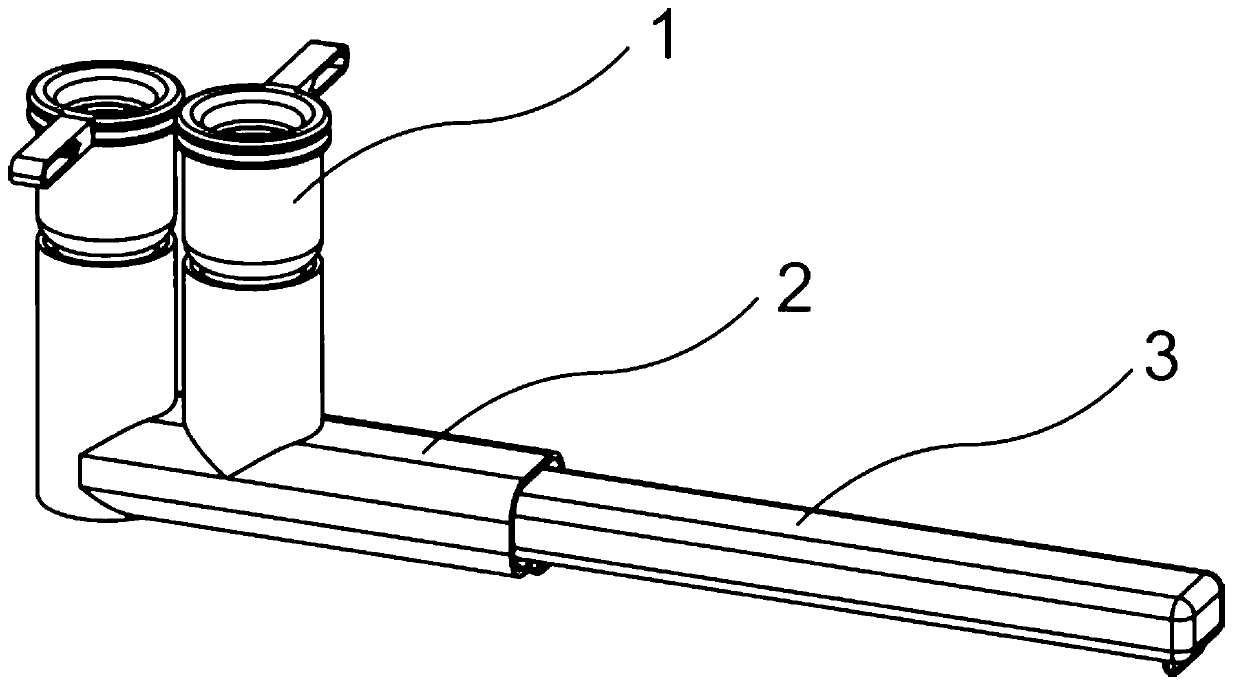

[0080] Such as figure 1 As shown, the present invention includes a device assembled from a plurality of components to guide liquid to flow to a lateral flow chromatography test paper in a closed space for detection reaction. The three components are stackable sealable reaction solution tube (hereinafter referred to as solution tube 1), sealable connecting tube (hereinafter referred to as connecting tube 2), and sealable test paper tube (hereinafter referred to as test paper tube 3). Solution tube 1 can be one or more, in figure 1 In the shown embodiment, two solution tubes 1 are used.

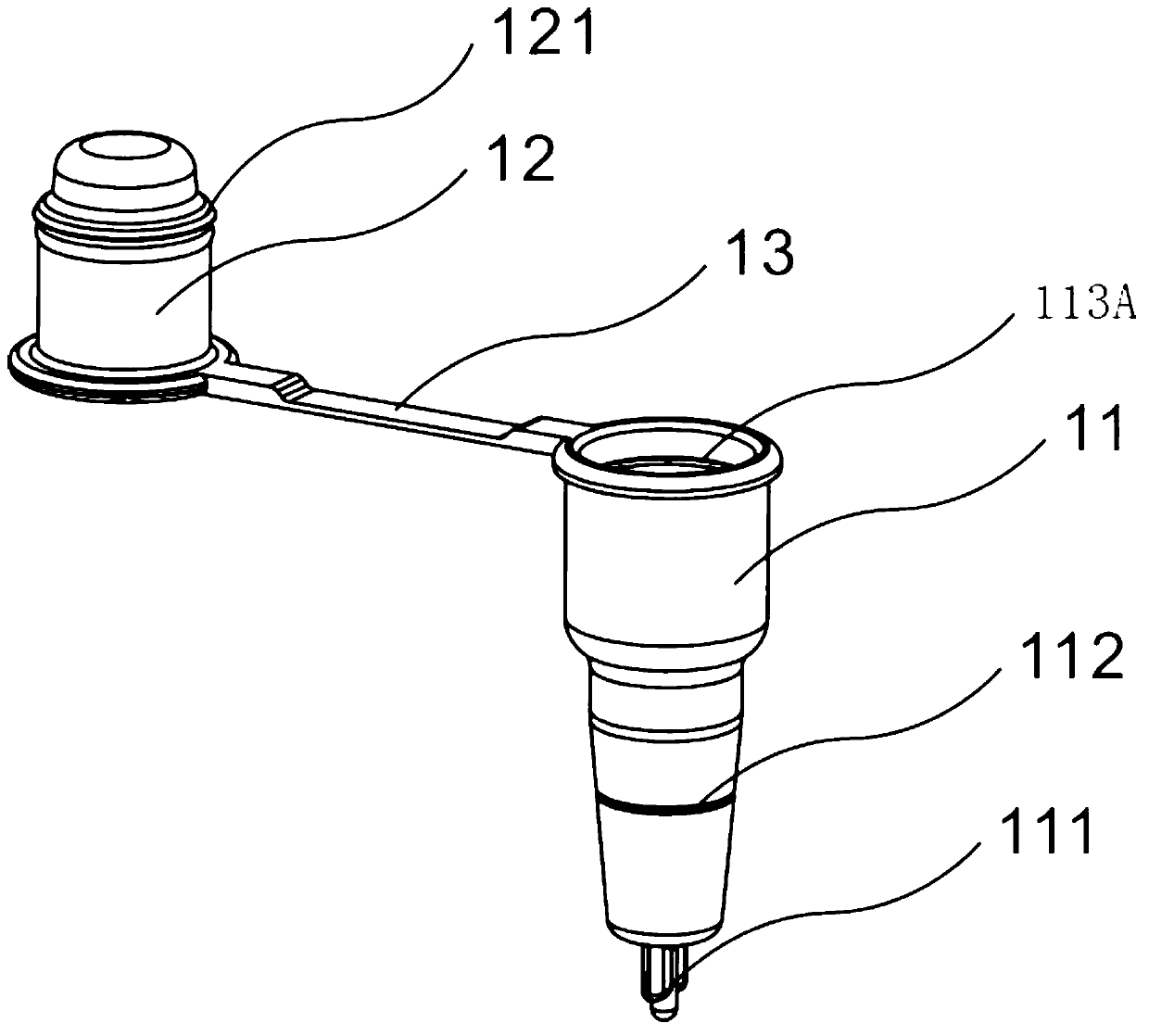

[0081] Such as figure 2 As shown, the solution tube 1 includes a solution tube body 11 and a solution tube cover 12, and the solution tube body 11 and the solution tube cover 12 are connected by a solution tube connecting bar 13; the solution tube body 11 includes the bottom of the solution tube from bottom to top Protrusion 111, solution pipe external groove 112, solution pipe internal gro...

Embodiment 2

[0099] When two kinds of test solutions are required to be tested after mixing and reacting, two solution pipes need to be stacked, and the device of the present invention can adopt another structure, such as Figure 4 As shown, a counterbore-shaped cavity 125 can be established on the top of the solution tube cover 12, and another solution tube can be inserted in this counterbore-shaped cavity 125 (see Figure 9 ); the bottom of the counterbore-shaped cavity 125 of the solution tube cover 12 is provided with a cut sheet 123 for the solution tube cover and a pit 124 for inserting and fitting the protrusion 111 at the bottom of the solution tube. The protrusion 111 at the bottom of the solution tube and the pit 124 are in-line or cross-shaped or other shapes of mutual fitting structure; the outer circumference of the solution tube cover 12 is provided with a raised sealing ring 121 on the outer circumference of the solution tube cover near the bottom of the cover, and the soluti...

Embodiment 3

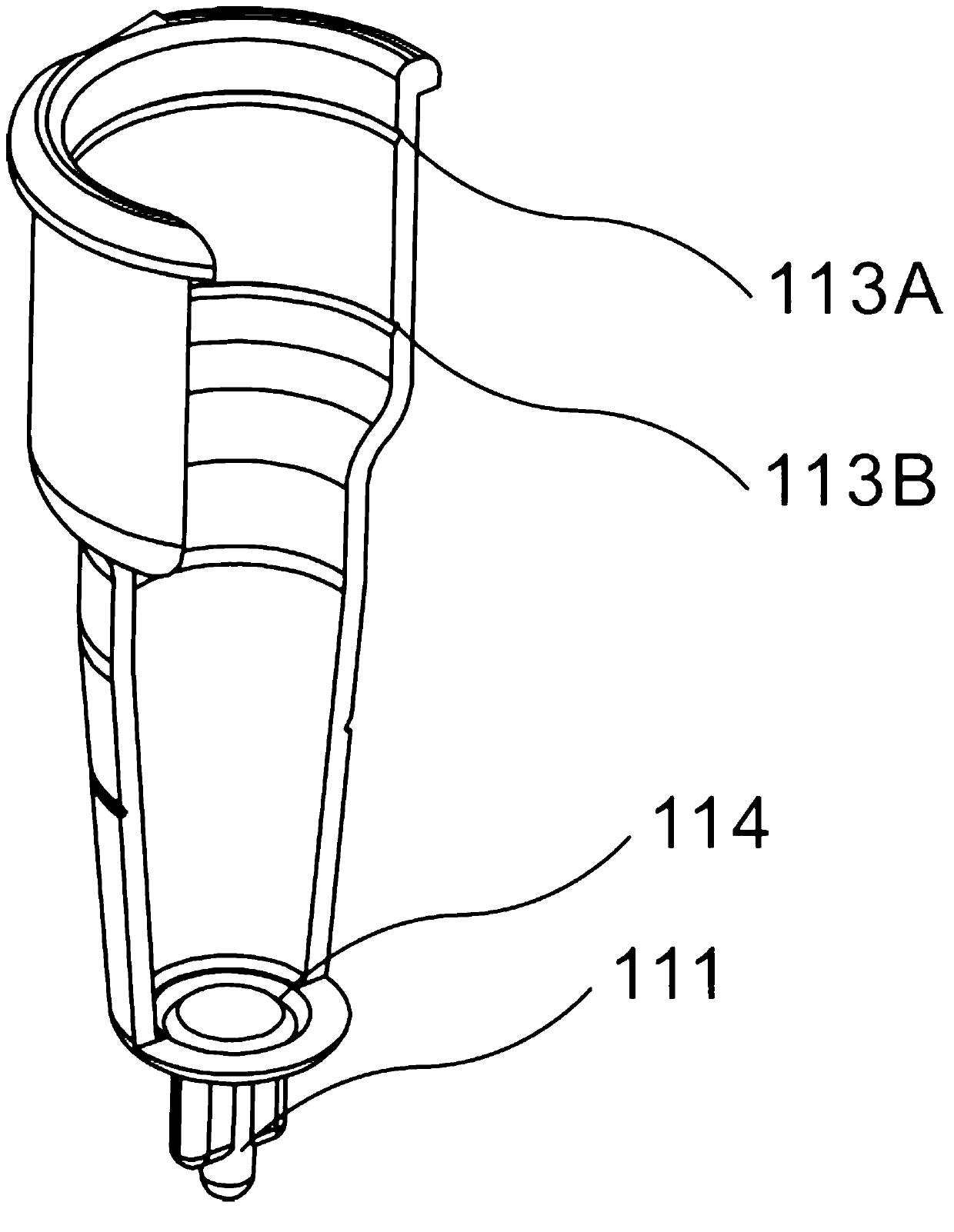

[0111] Such as Figure 11-13 As shown, the difference between this embodiment 3 and embodiment 1 is: the bottom structure of the solution tube is provided with a bottom cut 114, but there is no bottom protrusion; The solution channel hole 25B is composed of the raised part 25A against the bottom structure of the solution tube. When the bottom structure of the solution tube is subjected to the force of the raised part 25A against the top, it breaks away from the bottom cut 114. At this time, it is pre-packed in the solution tube. The sample solution in the tube 1 can flow out from the fracture gap, and flow to the sample solution receiving area of the chromatography test paper in the test paper tube through the solution channel hole 25B at the bottom of the connecting tube; the cut mark 114 at the bottom of the solution tube is a line or point shape, the material thickness of the cut part is 0.05-0.5mm less than that of other parts; when the bottom structure of the solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com