Preparation method of microchip for microprotein detection

A micro-protein and microchip technology, applied in the fields of plasma separation and protein detection, can solve problems such as reduced separation efficiency, blockage of filter membrane pores, and sample contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Plasma Separation and Protein Detection of Healthy Whole Blood

[0030] Using a microfluidic system to separate plasma from whole blood of healthy people and detect proteins, the specific steps are as follows:

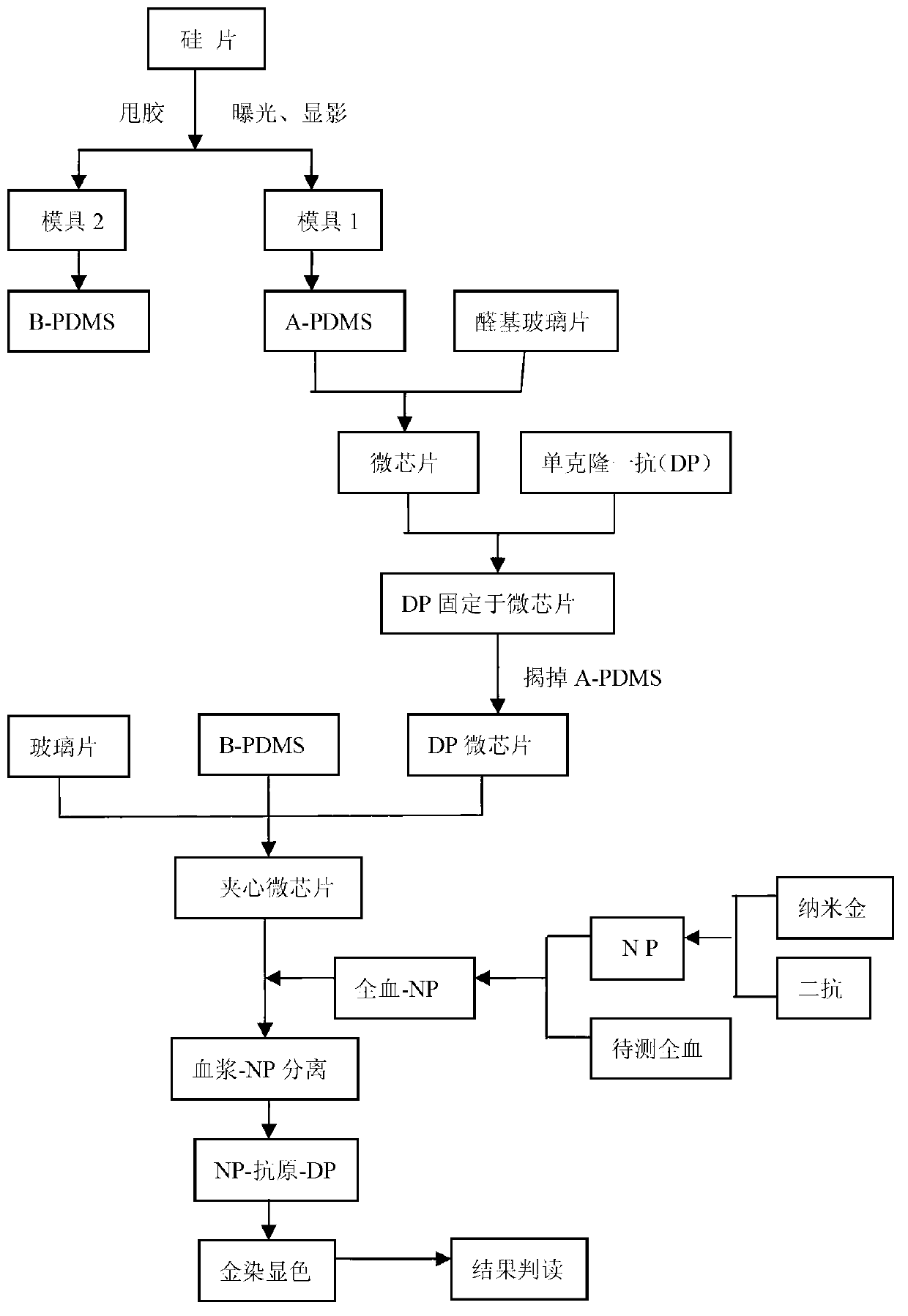

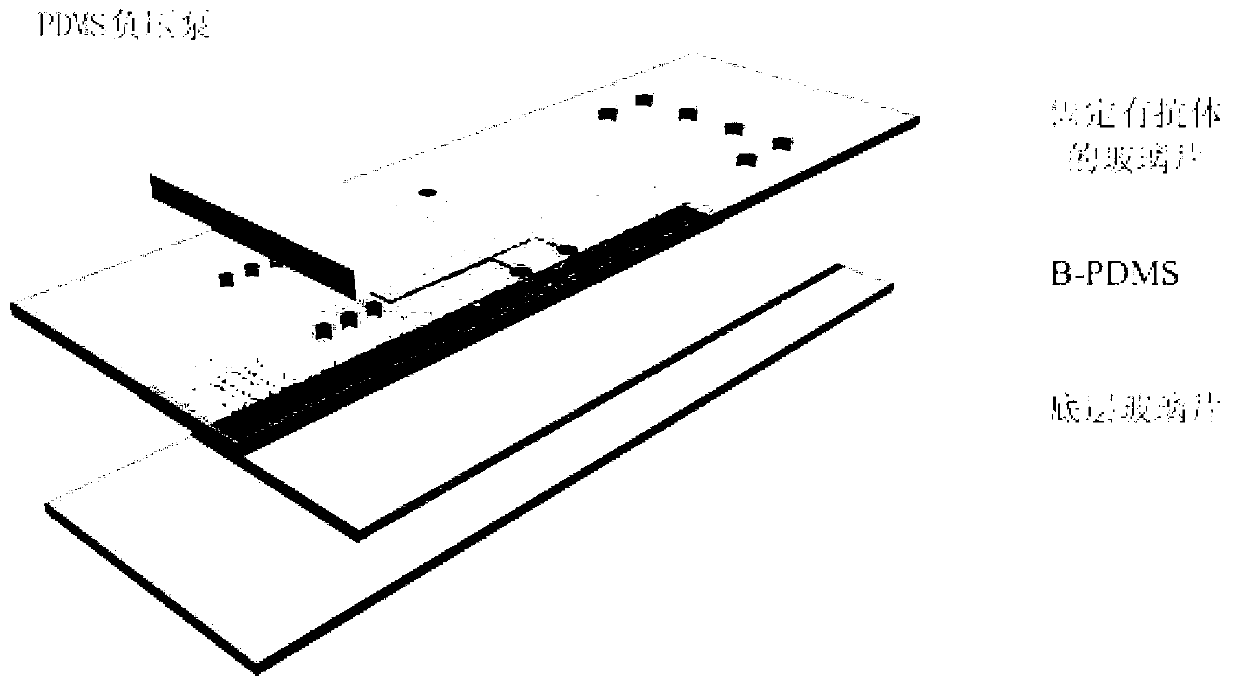

[0031] (1) Microfluidic chip preparation and protein immobilization

[0032] 1. Silicon wafer is used as the base material, and SU-8 photoresist is used as the mask layer to expose and develop the mold A for immobilizing the protein and the mold B for separation and detection;

[0033] 2. Mix PDMS and curing agent (Sylgard184curing agent) at a ratio of 10:1 (weight ratio), pour on mold A and mold B after removing air bubbles, heat and cure at 90°C for 1 hour, and make a microstructure;

[0034] 3. Peel off the PDMS block (A-PDMS) on mold A, punch the sample inlet and outlet holes with a punching needle, and then reversibly bond them together with the aldehyde-modified glass sheet;

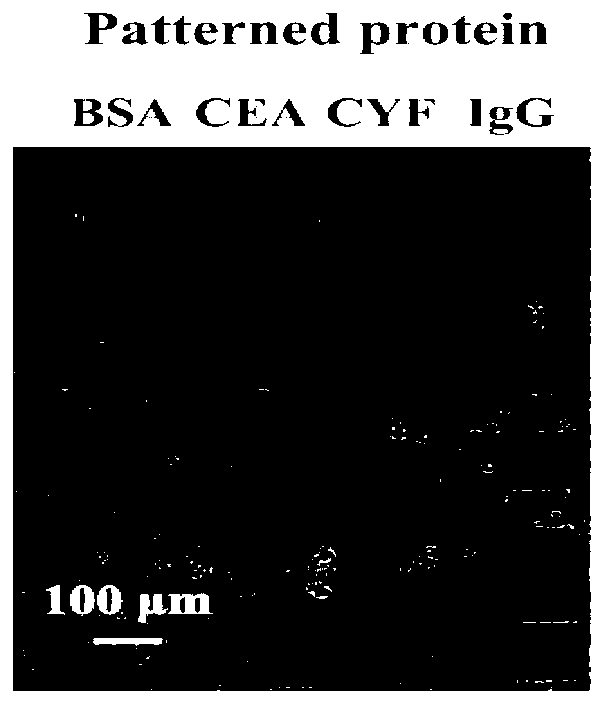

[0035] 4. Add 4 different primary antibody solutions (BSA, CEA, CyFRA21-1 and ...

Embodiment 2

[0050] Clinical whole blood plasma separation and protein detection

[0051] (1) Preparation of microfluidic chip

[0052] Same as (1) in Example 1.

[0053] (2) Preparation of gold nanoparticles and antibody labeling

[0054] Same as (2) in Example 1.

[0055] (3) Testing and interpretation of results

[0056] 1. Put the negative-pressured PDMS block in the sample hole of the sandwich microchip prepared above.

[0057] 2. Mix 10 μl of fresh lung cancer whole blood (contains CEA and CyFRA21-1 antigens identified in it), 0.5 μl of NP probe and mix evenly, take 3 μl of whole blood-NP mixed solution and add it to the injection port of the chip, under the action of negative pressure The blood flows into the microchannel, the blood cells naturally settle in the channel, the plasma / NP mixture flows into the detection area after separation, and forms a sandwich structure with the protein immobilized on the surface of the chip (i.e. NP-antigen-protein microchip), incubate at 37°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com