Method for preparing dual-curing single-component silk-screen printing photosensitive adhesive

A screen printing, dual-curing technology, applied in the field of preparation of dual-curing single-component screen printing photoresist, can solve the problems of pollution, poor water resistance, low initial strength, etc., and achieve improved comprehensive performance and high crosslinking density. , The effect of production process safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

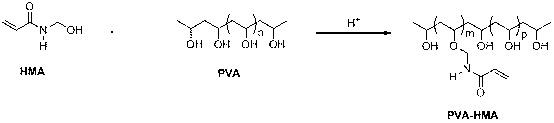

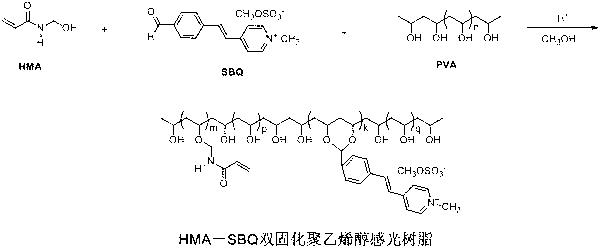

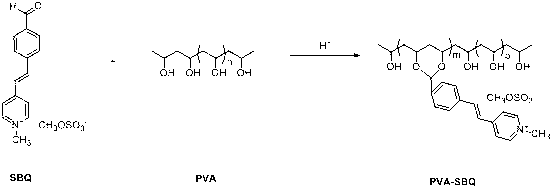

Method used

Image

Examples

Embodiment 1

[0020] Example 1, carried out under shading conditions, in a 1000 ml three-necked round-bottomed reaction bottle with mechanical stirring and a thermometer, add 600 ml of anhydrous methanol, add 100 grams of polyvinyl alcohol (PVA) 1788 (degree of polymerization) crushed to 200 mesh 1700, alcoholysis degree is 88%) powder, stirred and swelled at room temperature for 2 hours, added 15 grams of N-methylolacrylamide (HMA), 10 grams of N-methyl-4-formyl styryl pyridylmethyl Sulphate (SBQ), then add 0.1 g of 2,6-di-tert-butylphenol as a polymerization inhibitor, and 2 g of p-toluenesulfonic acid as a catalyst, heat up to 60 ° C, stir for 10 hours, and cool down to Room temperature, suction filtration, the filter cake is washed three times with methanol, each time with 50ml of methanol, the washed methanol is merged into the filtrate, the filter cake is dried to obtain 112 grams of light yellow powder HMA-SBQ dual-cure photosensitive resin product, the product has Good water solubil...

Embodiment 2

[0021] Embodiment two, in the filtrate that embodiment one produces, continue to add the powder of the pulverized polyvinyl alcohol 1788 of 100 grams. Stir at room temperature for 2 hours, add 12 gram of HMA monomer and 8 gram of SBQ photosensitizer, then can prepare about 115 gram of light yellow powder products according to the method of embodiment one, product performance has no significant difference with the first batch of products, filtrate Continue to apply mechanically for the third time, and the color of the product prepared is darker than that of the previous two batches, and the photosensitivity and water solubility slightly decline.

Embodiment 3

[0022] Example 3, take 15 grams of the prepared HMA-SBQ dual-curing photosensitive resin, add 85 grams of deionized water, and heat it to 80°C under stirring conditions to dissolve it to obtain a light yellow transparent aqueous solution, cool it down to 60°C, add 200 grams of solid 50% polyvinyl acetate emulsion, add dropwise 5ml of isopropanol solution containing 0.5g of water-soluble photoinitiator 2959, add a small amount of defoamer and dyeing agent, stir and mix at 60°C for 3 hours to obtain uniform silk Screen printing photosensitive emulsion, with a solid content of about 38%, can be used in the water-based screen printing industry; the screen printing plate made of this screen printing photosensitive emulsion has fast exposure speed, good bridging performance, and high resolution , high printing durability of the screen plate, because the screen printing photosensitive adhesive is a one-component product, there is no obvious change in product performance after one year...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com