Entry plate for drilling

A cover plate and resin composition technology, applied in metal processing, electrical components, printed circuit manufacturing, etc., can solve problems such as gaps and slow development of printed circuit board technology, achieve excellent hole position accuracy, reduce drill damage, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

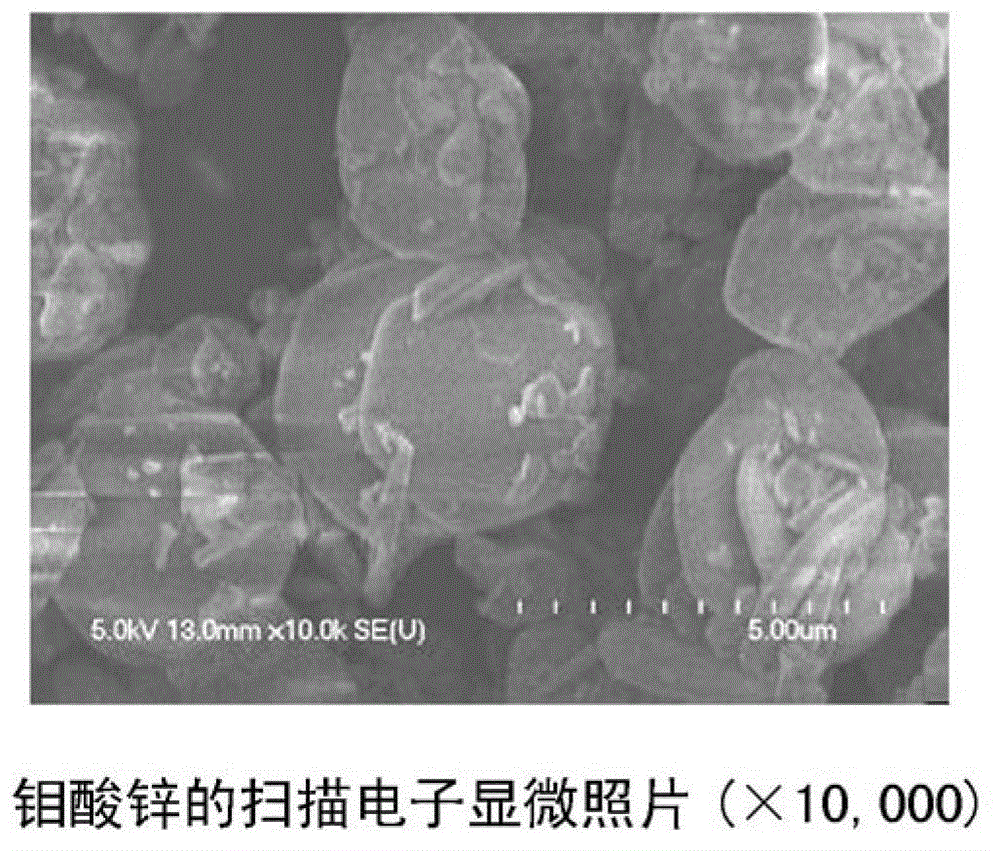

[0068] 30 parts by weight of polyethylene oxide (ALTOP MG-150, manufactured by Meisei Chemical Works, Ltd.) with a weight average molecular weight of 150,000 and 70 parts by weight of polyethylene glycol (PEG20000, manufactured by Sanyo Chemical Industries, Ltd.) with a weight average molecular weight of 20,000 were mixed. Ltd.) was dissolved in a mixed solution of water / MeOH (methanol) so that the resin solid content was 30%. At this point, the ratio of water to MeOH is 60 / 40. In addition, 5 parts by weight of zinc molybdate (manufactured by Nippon Inorganic Colour & Chemical Co., Ltd, particle diameter 0.4 μm to 13 μm, average particle diameter 3μm) as solid lubricant (B), and fully dispersed. The solution of the water-soluble resin composition was applied to an aluminum foil having an epoxy resin film having a thickness of 0.01 mm formed on one surface using a bar coater (aluminum foil used: 1N30, thickness 0.1 mm, manufactured by Mitsubishi Aluminum Co, Ltd. . system) so...

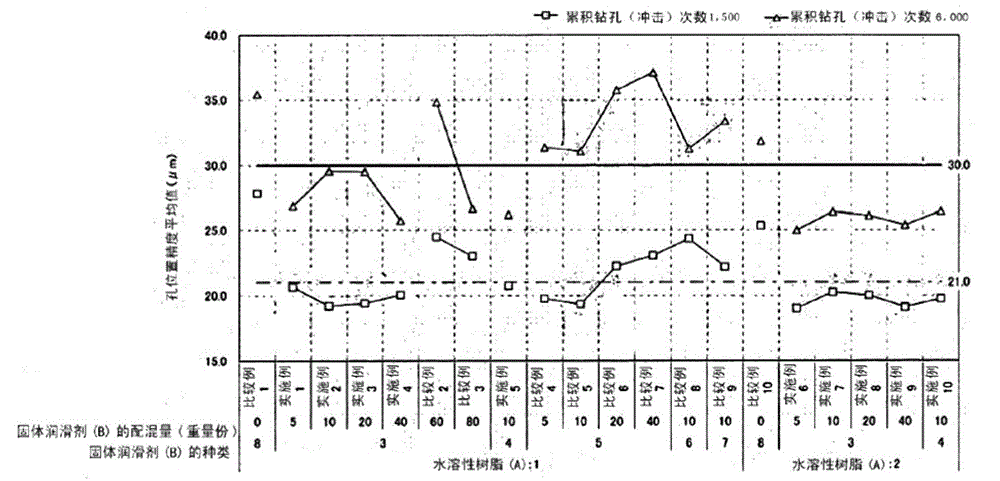

Embodiment 2 to 14

[0070] The water-soluble resin composition shown in Table 1 was prepared according to the method of Example 1, thereby producing an entry sheet for drilling having a thickness of the water-soluble resin composition layer after drying of 0.05 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com