Technological process for treating casting surface

A process method and casting technology, applied in the field of casting production and manufacturing, can solve the problems of molten iron scouring and falling, efficiency decline, failure, etc., and achieve the effects of stable coating performance, reduced leakage rate, and grain refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

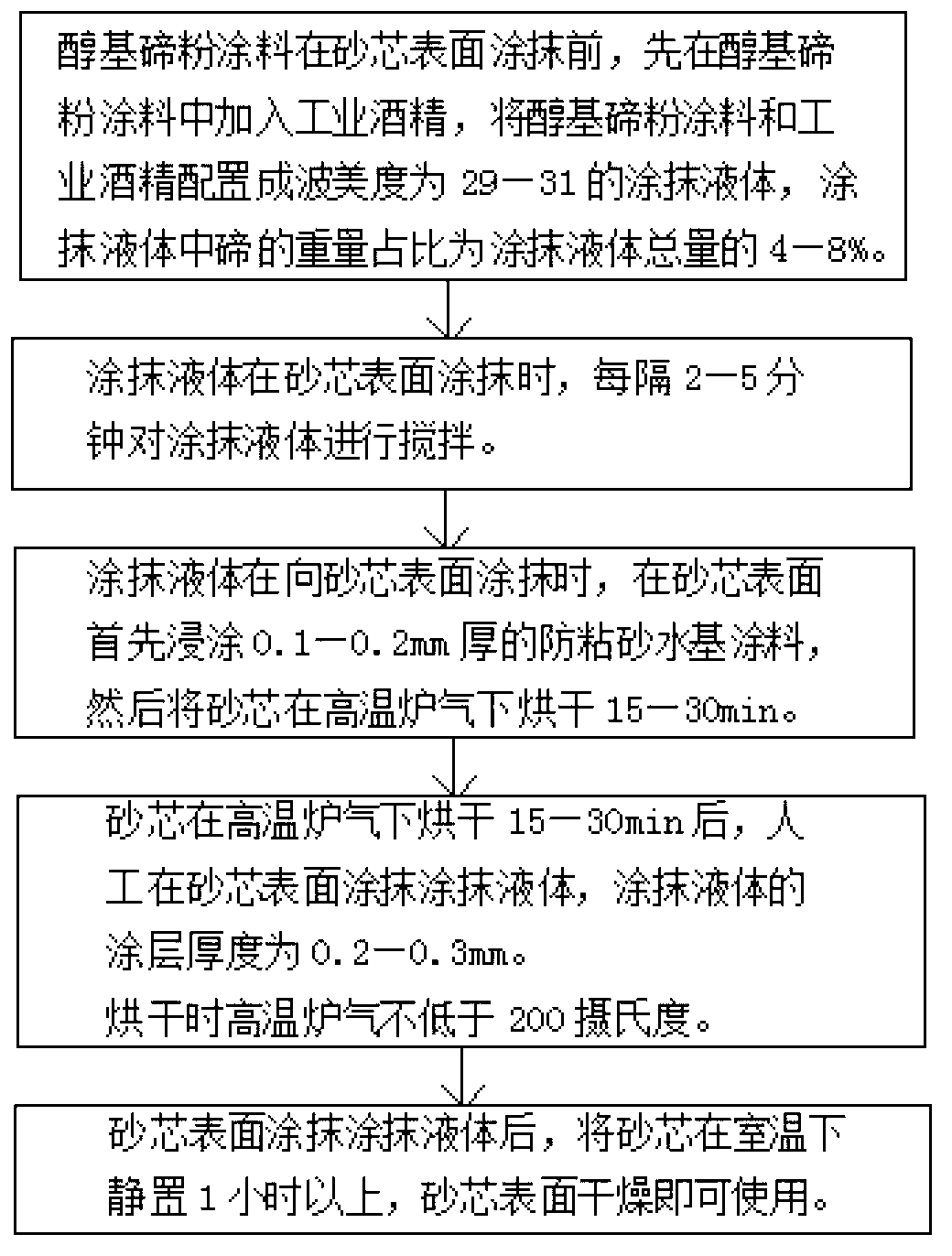

[0014] In the following, referring to the drawings, through the description of the embodiments, the specific embodiments of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, etc. Detailed description:

[0015] As attached figure 1 As shown, the present invention is a process method for treating the surface of a casting. The casting is formed by a sand mold and a sand core fixed in the sand mold. The process method includes applying alcohol to the surface of the sand core. The process steps of tellurium-based powder coating, before the alcohol-based tellurium powder coating is applied on the surface of the sand core, industrial alcohol is added to the alcohol-based tellurium powder coating, and the alcohol-based tellurium powder coating and industrial alcohol are configured to a Baume degree of 29-31 The smear liquid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com