Wire cutting machine and groove path device therefore

A wire cutting machine and cutting wire technology, applied in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of insufficient introduction force, no assumed pressure, rise, etc., so as to improve cutting efficiency and improve cutting performance. , the effect of suppressing splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

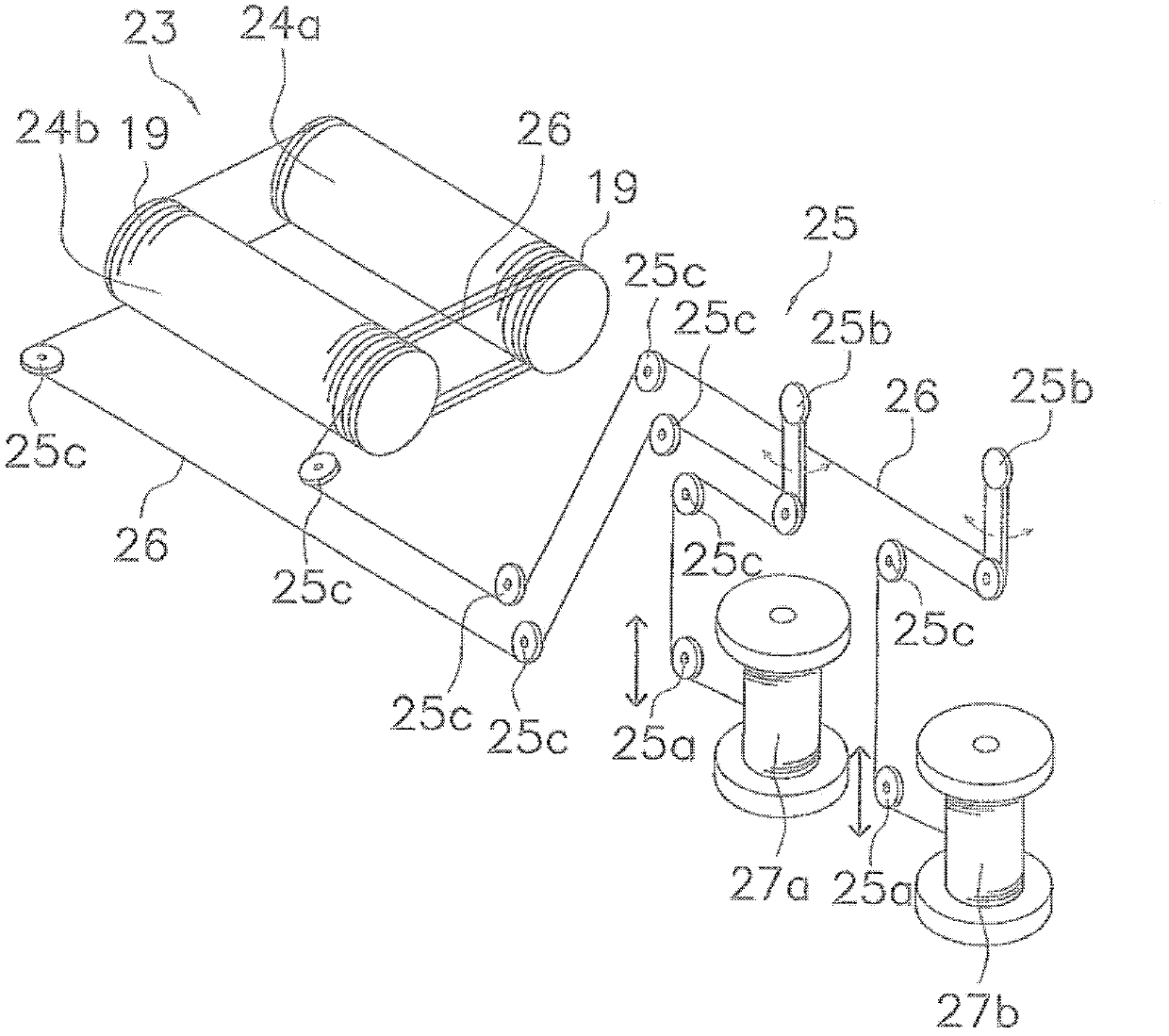

[0165] In this embodiment, confirm the use Figure 7 When the shown channel member 40 performs the cutting of the workpiece W, the feed speed of the workpiece W relative to the cutting line 26 (hereinafter referred to as the feed speed of the workpiece W), the traveling speed of the cutting line 26, and the working fluid S are changed Experiment of cutting performance under each condition of supply amount.

[0166] In addition, in Figure 7 In the channel part 40, Figure 5 The illustrated channel member 40 and the front end member 44 have different structures, and have a shape with a wide opening.

[0167] In addition, in this embodiment, as Figure 7 As shown, the distance between the front end member 44 of the first channel 42 and the opposite surface W1 of the workpiece W is set to 7 mm, the distance between the lower member 43 and the opposite surface W1 of the workpiece W is set to 5 mm, and the second processing The distance between the upper plate and the lower plate of the...

Embodiment 2

[0181] In this embodiment, confirm the use Picture 11 and Picture 12 (a)~ Picture 12 (c) When the three kinds of channel members 40 shown in FIG. 4 cut the workpiece W, an experiment in which the feed rate of the workpiece W and the supply amount of the machining fluid S are changed under the conditions of cutting performance.

[0182] (Channel)

[0183] Specifically, such as Picture 11 As shown, as the channel 1, the distance between the front end member 44 of the first channel 42 and the opposite surface W1 of the workpiece W is set to 7 mm, and the distance between the lower member 43 and the opposite surface W1 of the workpiece W is set to 5mm, the distance between the upper and lower plates of the third machining fluid supply space S3 is set to 11mm, and the height distance of the front end opening of the second machining fluid supply space S2 opposite to the opposite surface W1 of the workpiece W is set to 23mm 的channel part 40.

[0184] In addition, as the channel 2, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com