Process for preparing hydrogen by strengthening chemical chain reforming in continuous catalytic adsorption manner via moving bed

A technology for reforming hydrogen production and chemical chain, applied in chemical recycling, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high energy consumption, increased hydrogen production cost, inability to carry out engineering applications, etc., and achieves reduction of hydrogen production reaction temperature. , The effect of reducing energy consumption for hydrogen production and continuous and stable production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

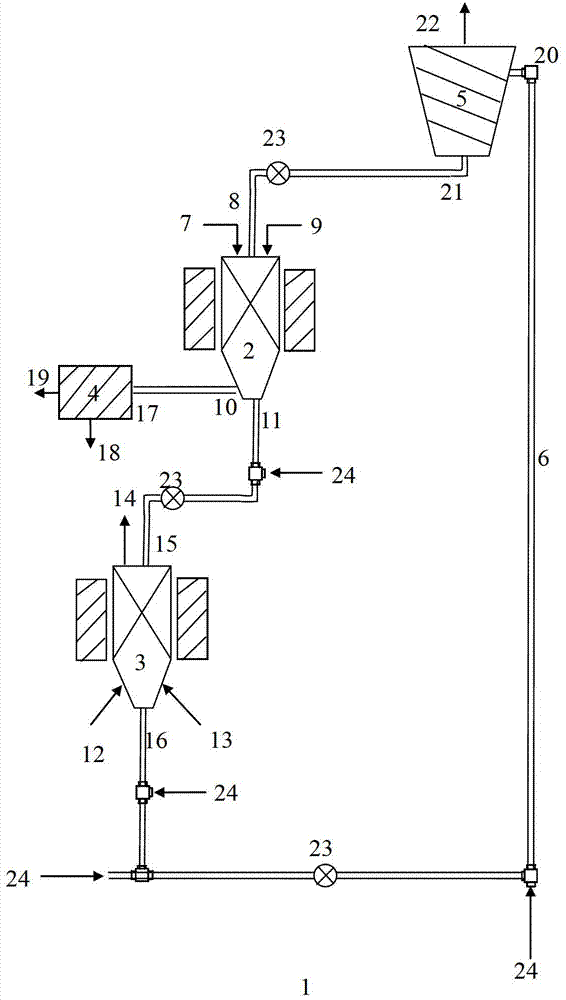

Method used

Image

Examples

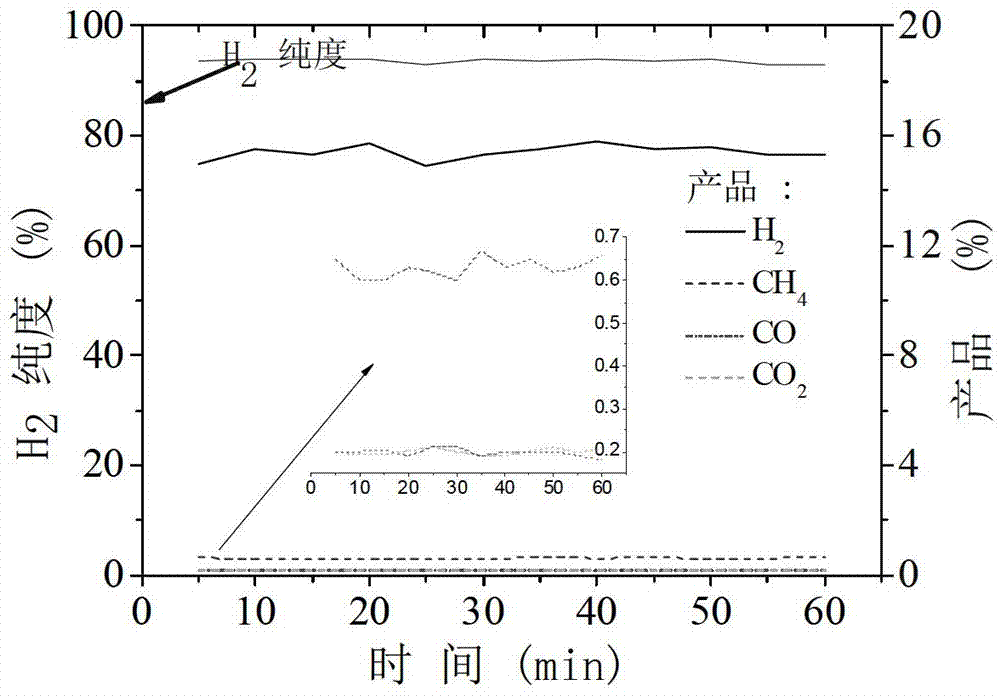

Embodiment 1

[0037] The carbon content of water vapor and biodiesel by-product glycerol is sent to the reformer according to the molar ratio S / C of 20.8 / 1.78, wherein the flow rate of water vapor is: 0.3×10 -3 m 3 min -1 (STP), the temperature of the reformer starts to supply heat externally to 500°C to start the hydrogen production operation. Due to the heat generated by partial oxidation, the temperature rises, the external heat supply stops, and the reactor itself generates heat to maintain the reforming hydrogen production process. When the temperature of the reformer drops to 500°C, the external heat source starts to supply heat, so the temperature of the reformer has been fluctuating between 500-530°C, the temperature of the regenerator is maintained at a constant 850°C, and the particle size of the catalyst and the adsorbent are uniform. (0.40-0.90) mm, the moving rate of the catalyst and adsorbent in the reformer and regenerator is maintained at 10.0 cm / min, the device runs for 60...

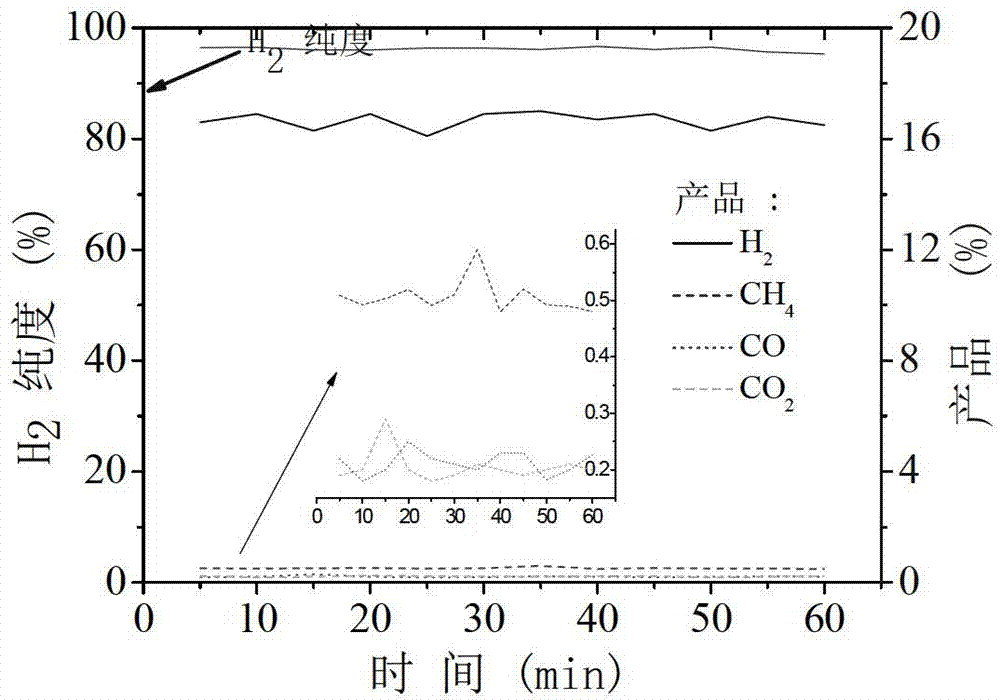

Embodiment 2

[0039] The carbon content of water vapor and biodiesel by-product glycerol is sent to the reformer according to the molar ratio S / C of 16 / 1, and the flow rate of water vapor is: 0.3×10 -3 m 3 min -1 (STP), the temperature of the reformer starts the external heat supply to 550 °C to start the hydrogen production operation, and the heat generated by the partial oxidation of the hydrogen production reaction makes the temperature of the reformer rise. At this time, the external heat supply is stopped, and the reactor Self-heating maintains the reforming hydrogen production process. When the temperature of the reformer drops to 550°C, the external heat source starts to supply heat, so the temperature of the reformer has been fluctuating between 550-578°C, and the temperature of the regenerator remains constant at 900 ℃, the particle size of catalyst and adsorbent are both (0.40-0.90) mm, the moving speed of catalyst and adsorbent in the reformer and regenerator are maintained at 1...

Embodiment 3

[0041] The carbon content of water vapor and biodiesel by-product glycerin is sent to the reformer according to the molar ratio S / C of 15 / 1, wherein the flow rate of water vapor is: 0.3×10 -3 m 3 min -1 (STP), the temperature of the reformer starts the external heat supply to 550 °C to start the hydrogen production operation, and the heat generated by the partial oxidation of the hydrogen production reaction makes the temperature of the reformer rise. At this time, the external heat supply is stopped, and the reactor Self-heating maintains the reforming hydrogen production process. When the temperature of the reformer drops to 600°C, the external heat source starts to supply heat, so the temperature of the reformer has been fluctuating between 600-620°C, and the temperature of the regenerator remains constant at 900 ℃, the particle size of the catalyst and the adsorbent are both (0.40-0.90) mm, the moving speed of the catalyst and the adsorbent in the reformer and the regener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com