Method for preparing modified activated carbon at normal pressure

An activated carbon and modified technology, applied in chemical instruments and methods, inorganic chemistry, ion exchange, etc., can solve the problems of increasing the operating cost of the preparation process, and achieve the effect of saving the preparation cost and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

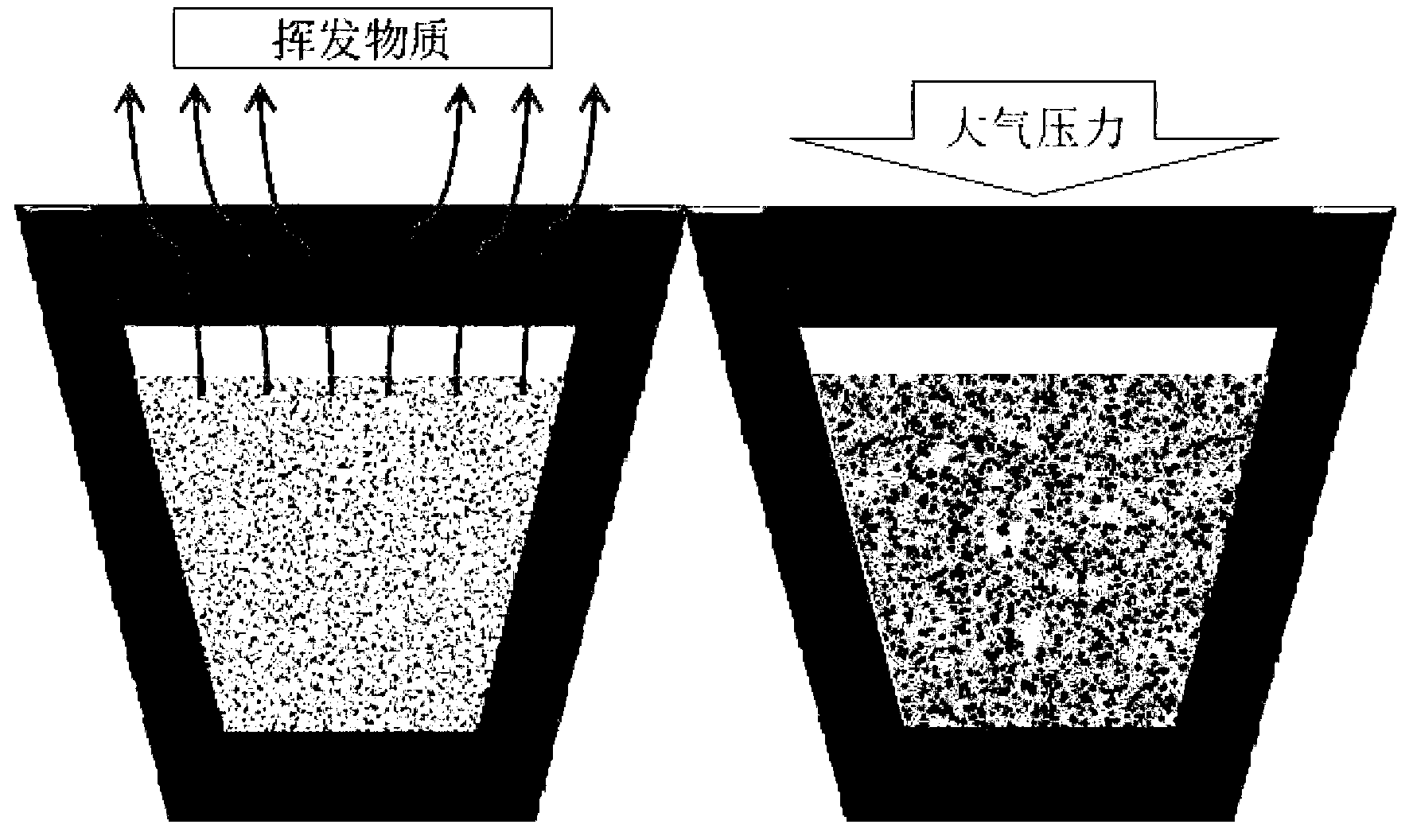

Method used

Image

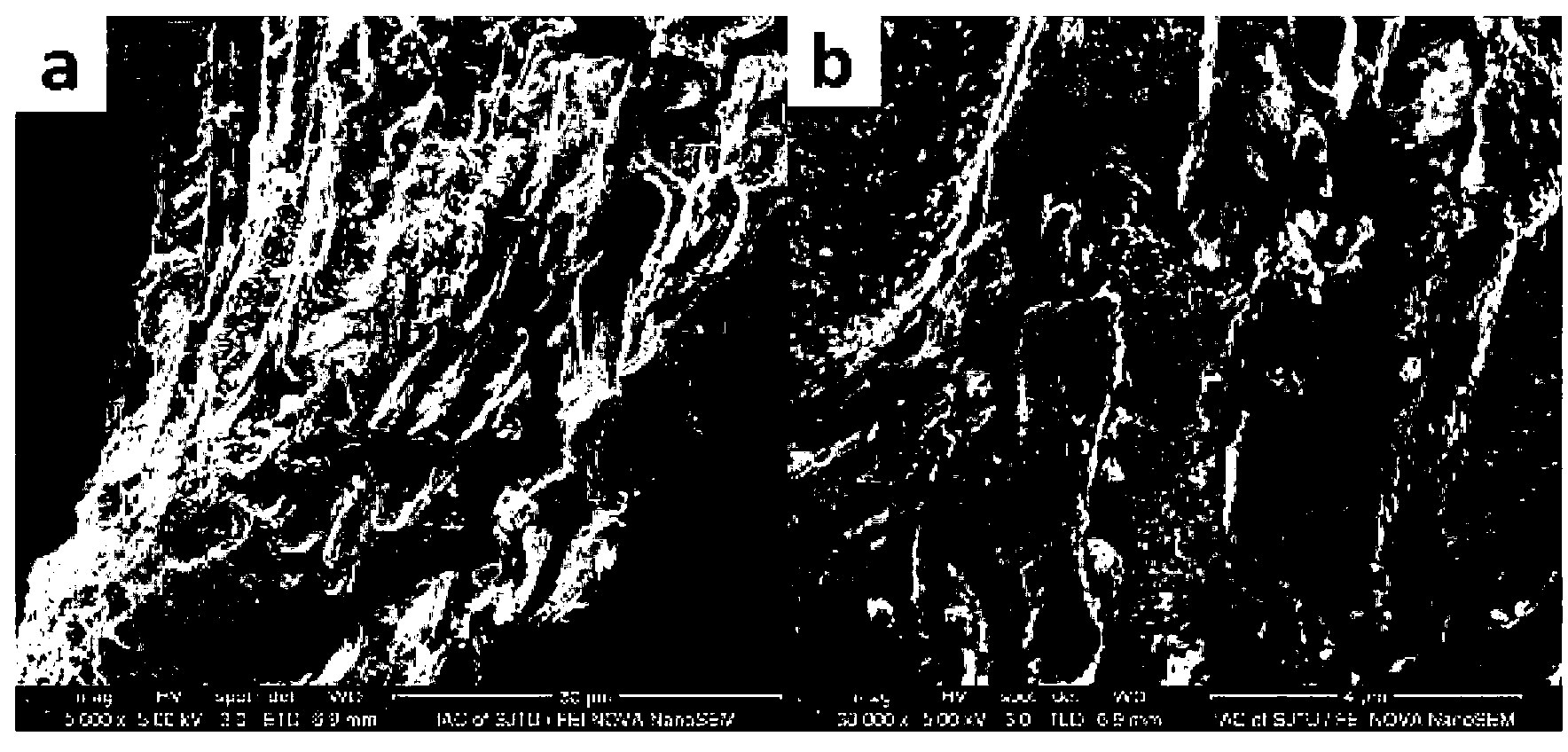

Examples

Embodiment 1

[0028] Mix 3g of straw powder with 3mL of calcium acetate solution (the concentration of calcium acetate solution is 10% by mass) in a beaker. Ultrasound for 5 minutes, stand still for 5 minutes, repeat the ultrasound three times, and stand at room temperature for 3 hours. Then the straw powder / calcium acetate mixture was dried in an oven at 180° C. and kept at 180° C. for 1 h. Add 60mL of zinc chloride solution (mass percentage concentration of zinc chloride solution is 10%) to the dried mixture, ultrasonic for 5 minutes, stand for 5 minutes, repeat three times, stir, so that the sample and solution are fully mixed, and stand at room temperature 3h. Then the mixture was baked in an oven at 110°C until it became viscous, and then the precursor was transferred to a crucible and compacted. Cover the crucible and place it in a muffle furnace, raise the temperature to 700°C, keep it for 1h, cool to room temperature and take out the modified activated carbon. Grind the block act...

Embodiment 2

[0030] Mix 3g of straw powder with 3mL of calcium acetate solution (the concentration of calcium acetate solution is 10% by mass) in a beaker. Ultrasound for 5 minutes, stand still for 5 minutes, repeat the ultrasound three times, and stand at room temperature for 3 hours. Then the straw powder / calcium acetate mixture was dried in an oven at 180° C. and kept at 180° C. for 1 h. Add 45mL of zinc chloride solution (mass percentage concentration of zinc chloride solution is 10%) to the dried mixture, ultrasonic for 5min, stand for 5min, repeat three times, stir, so that the sample and solution are fully mixed, and stand at room temperature 3h. Then the mixture was baked in an oven at 110°C until it became viscous, and then the precursor was transferred to a crucible and compacted. Cover the crucible and place it in a muffle furnace, raise the temperature to 700°C, keep it for 1h, cool to room temperature and take out the modified activated carbon. Grind the block activated car...

Embodiment 3

[0032] Mix 3g of straw powder with 3mL of calcium acetate solution (the concentration of calcium acetate solution is 10% by mass) in a beaker. Ultrasound for 5 minutes, stand still for 5 minutes, repeat the ultrasound three times, and stand at room temperature for 3 hours. Then the straw powder / calcium acetate mixture was dried in an oven at 180° C. and kept at 180° C. for 1 h. Add 30mL of zinc chloride solution (mass percentage concentration of zinc chloride solution is 10%) to the dried mixture, ultrasonic for 5 minutes, stand for 5 minutes, repeat three times, stir, so that the sample and solution are fully mixed, and stand at room temperature 3h. Then the mixture was baked in an oven at 110°C until it became viscous, and then the precursor was transferred to a crucible and compacted. Cover the crucible and place it in a muffle furnace, raise the temperature to 700°C, keep it for 1h, cool to room temperature and take out the modified activated carbon. Grind the block act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com