Method for preparing multi-stage hierarchical structure super-hydrophobic material

A hierarchical structure and super-hydrophobic technology, which is applied in chemical instruments and methods, other chemical processes, silicon oxide, etc., can solve the problems that cannot realize the characteristics of super-hydrophobic performance, and achieve the effect of excellent super-hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the preparation method of a kind of multi-level hierarchical structure superhydrophobic material of this embodiment is carried out according to the following steps:

[0023] 1. Preparation of polystyrene nanoparticle sol solution: Mix deionized water and styrene in a container loaded with polytetrafluoroethylene stirring paddles at a stirring speed of 280rpm to 320rpm, and continue to mix at a stirring speed of 280rpm to 320rpm. Add α-methyl methacrylate at 320rpm, reflux at a temperature of 40-60°C for 8min-12min, then add K 2 S 2 o 8 , constant temperature reaction at 75~85°C for 1.5h~2.5h to obtain polystyrene nanoparticle sol solution; wherein the volume ratio of deionized water and styrene is (4~6):1, and the α - the volume ratio of methyl methacrylate and styrene is (4~6): 100, the K 2 S 2 o 8 The ratio of the mass of styrene to the volume of styrene is (0.4~0.6) g: 100mL;

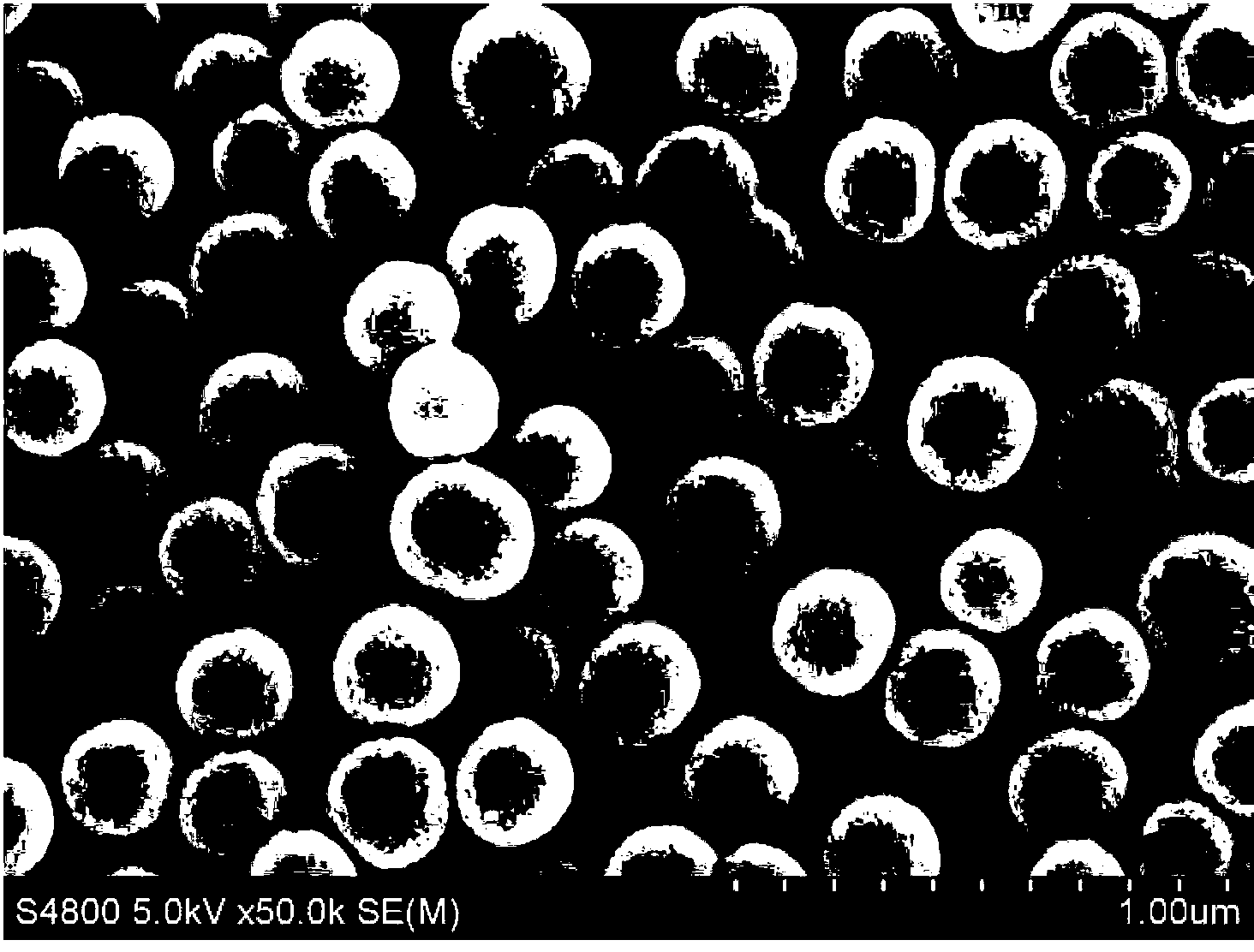

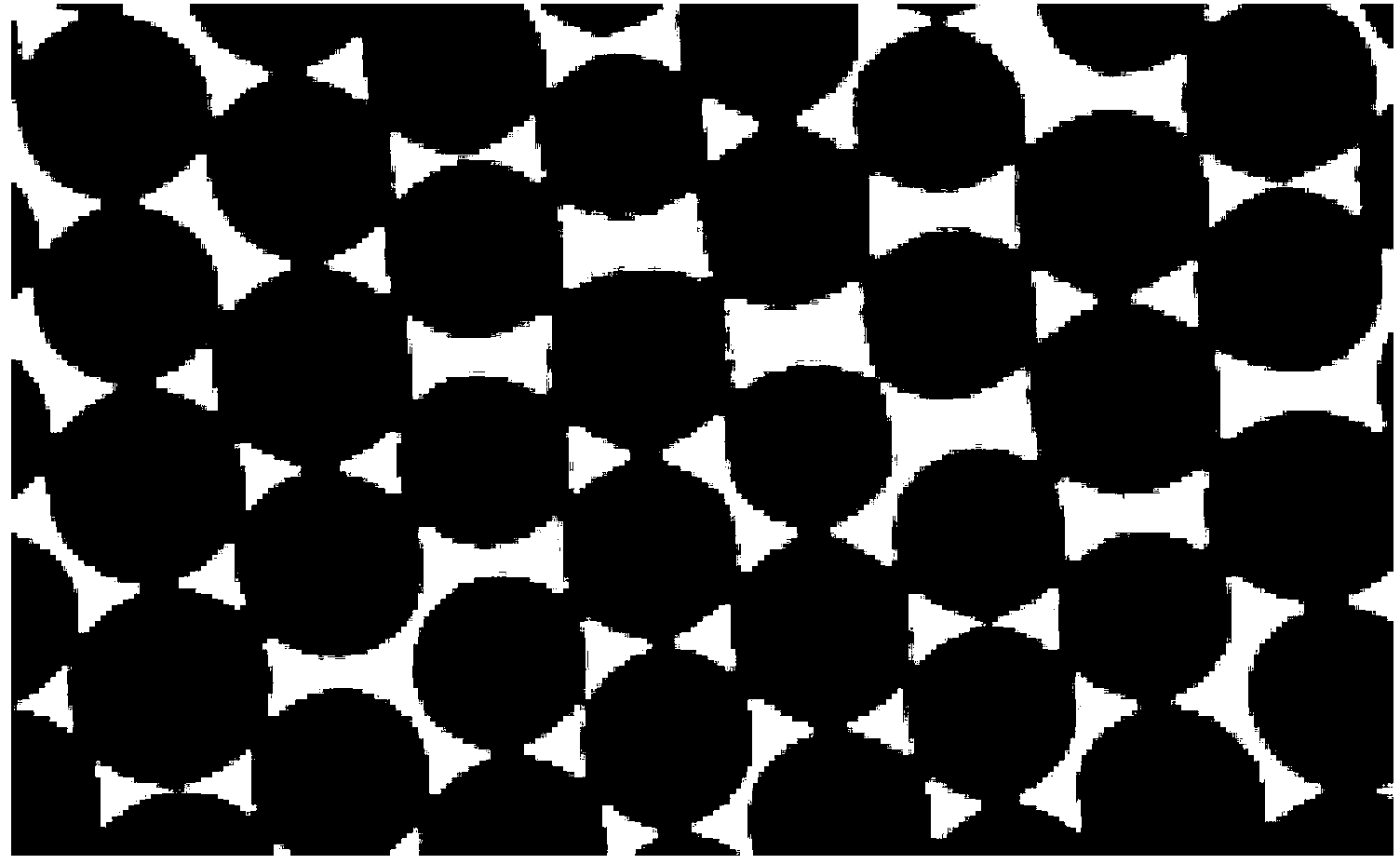

[0024]2. Preparation of polystyrene mesoporous silica nanop...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step two, cetyltrimethylammonium bromide solution is added at a rate of 2 mL / min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

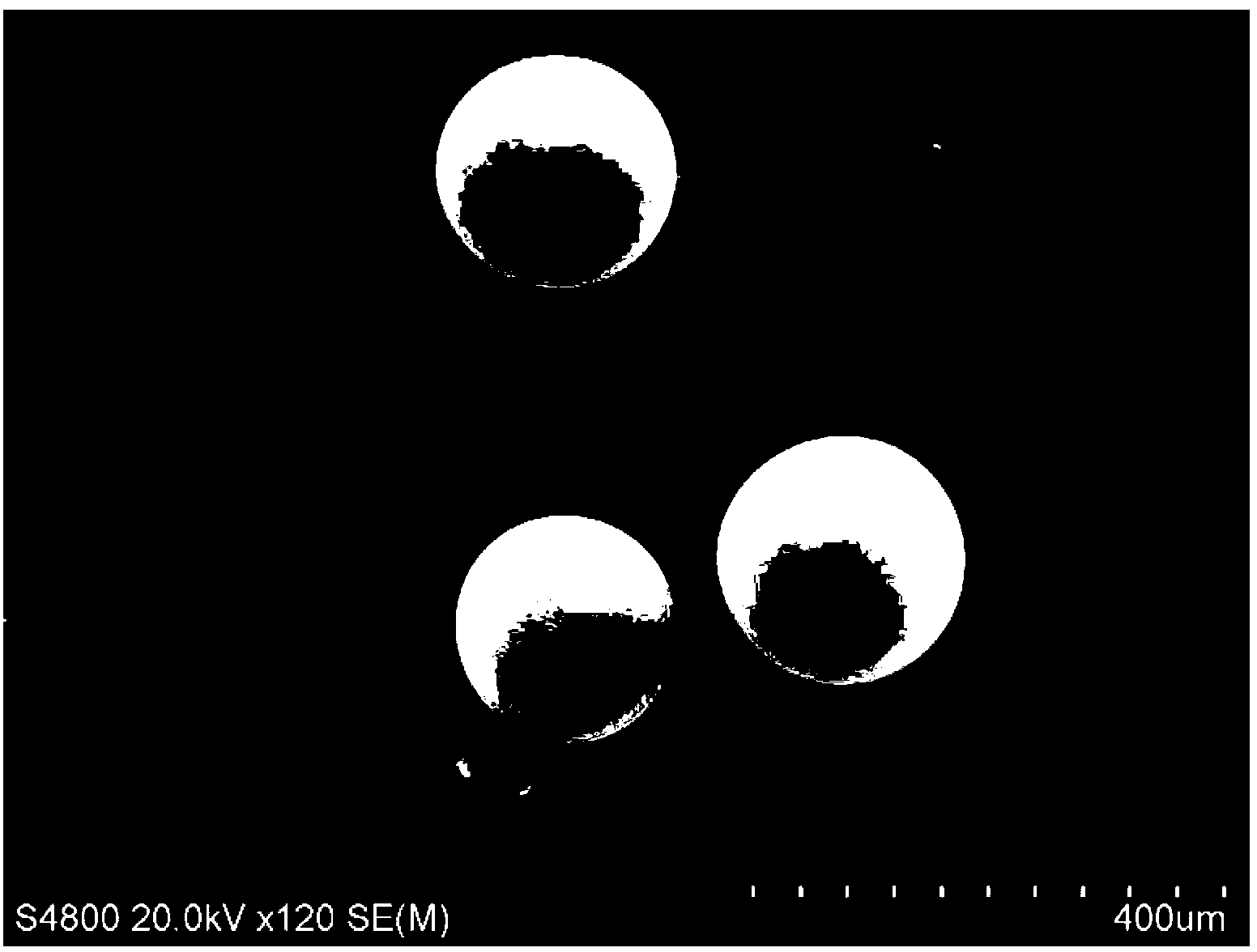

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the particle diameter of the polystyrene mesoporous silica nanoparticle precursor of the core-shell structure obtained in step two described in step three is 200nm . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com