Block copolymer and methods relating thereto

A technology of block copolymers and diblock copolymers, which can be used in other household appliances, devices for coating liquid on surfaces, coatings, etc., and can solve the problems of block copolymer orientation control and long-range order difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

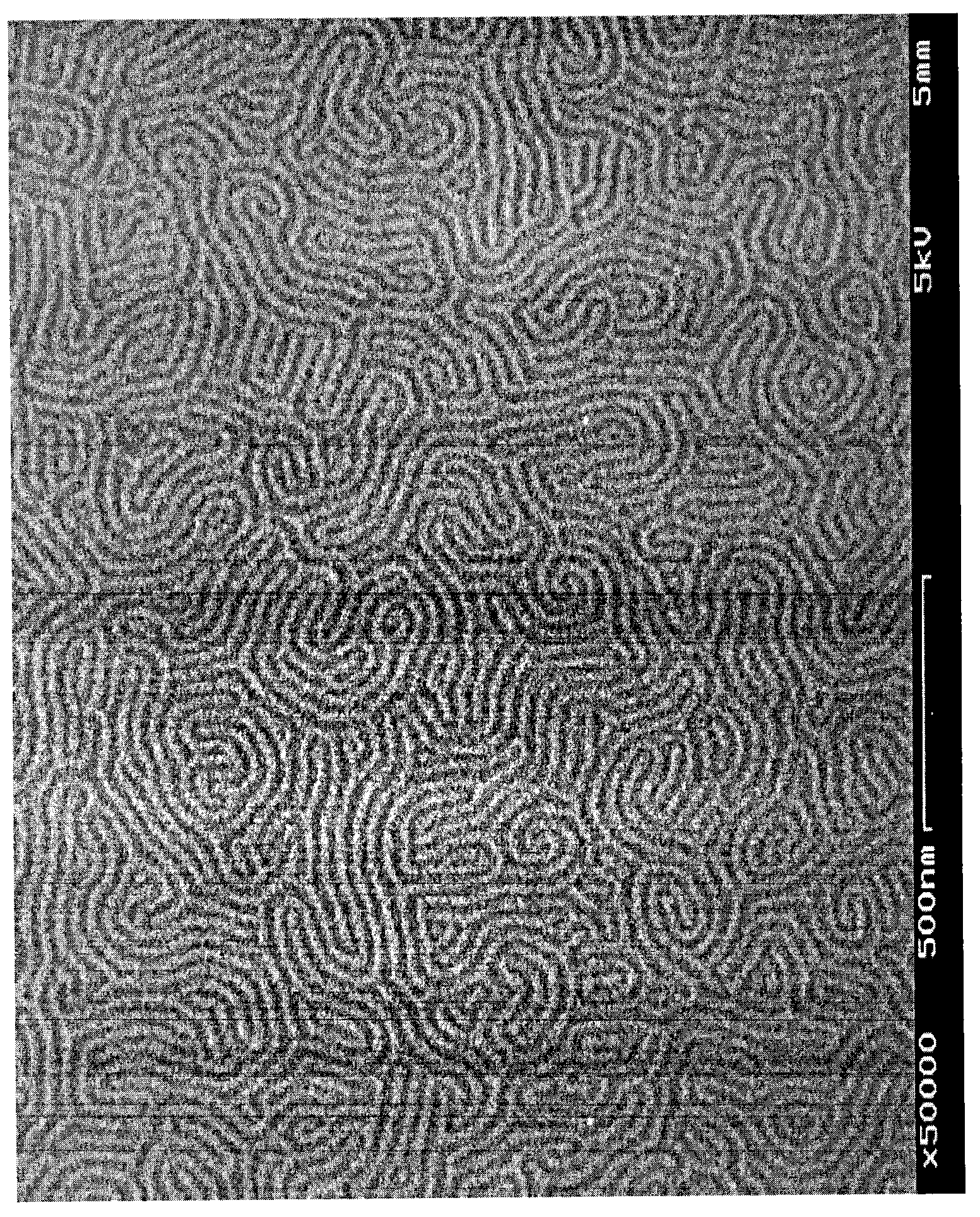

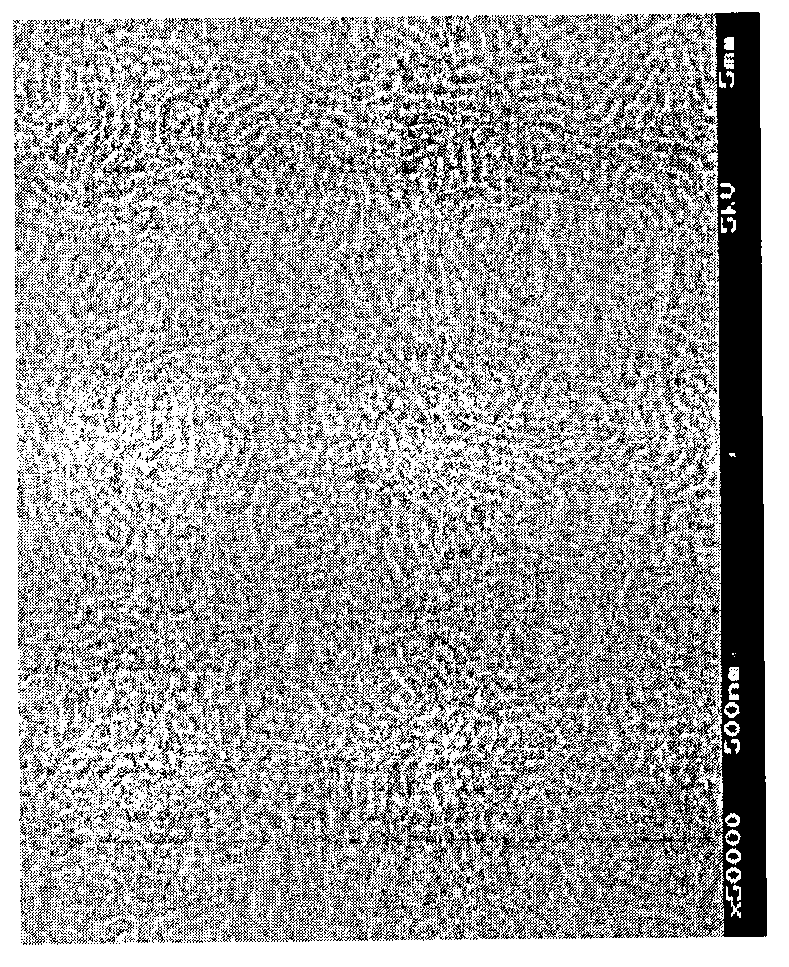

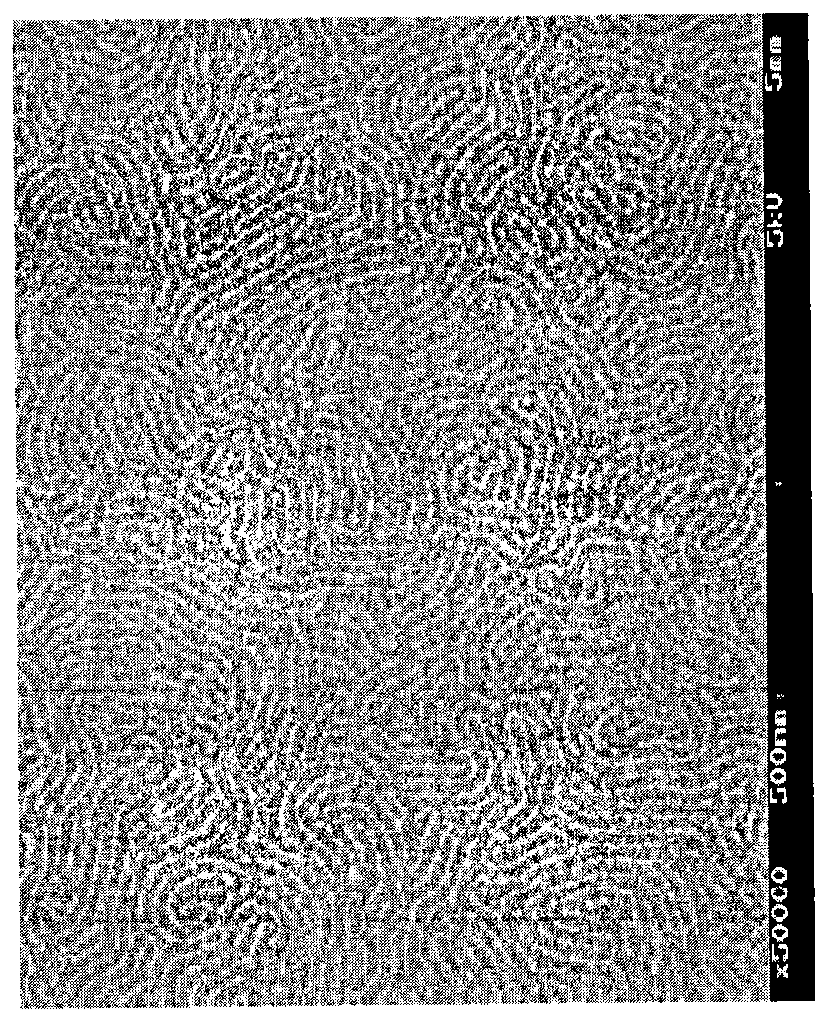

Image

Examples

Embodiment 1

[0053] Example 1: Preparation of hydroxyl-terminated polyethylene brushes

[0054] Cyclohexane (1500 g) was added in a 2 liter glass reactor under nitrogen atmosphere. Styrene (50.34 g) was then added to the reactor via cannula. The contents of the reactor were then heated to 40°C. A solution of sec-butyllithium (19.18 g) diluted at 0.32 M in cyclohexane was then added rapidly to the reactor via cannula, causing the contents of the reactor to turn yellow. The contents of the reactor were stirred for 30 minutes. The reactor contents were then cooled to 30°C. Ethylene oxide (0.73 g) was then sent to the reactor. The contents of the reactor were stirred for 15 minutes. 20 mL of a 1.4 M solution of HCl in methanol was then added to the reactor. The polymer in the reactor was then isolated by precipitation in isopropanol at a ratio of 500 mL polymer solution / 1250 mL isopropanol. The resulting precipitate was then filtered and dried in a vacuum oven at 60°C overnight to yie...

Embodiment 2

[0057] Embodiment 2: prepare PMMA-b-PTMSMMA diblock copolymer

[0058] In a 500 mL 3 neck round bottom reactor under argon atmosphere was added tetrahydrofuran ("THF") (113 g). The THF was then cooled to -78°C in the reactor. A 0.36M solution of sec-butyllithium in cyclohexane was then titrated into the reactor contents until the reactor contents exhibited a solid pale yellow color. The contents of the reactor were then warmed and held at 30°C until the color of the material disappeared completely (approximately 10-15 minutes). 1,1-Diphenylethylene (0.116 g) diluted in cyclohexane (2.278 g) was then cannulated into the reactor. The reactor contents were then cooled to -78°C. Sec-butyllithium (6.15 g) diluted at 0.065 M in cyclohexane was then rapidly added to the reactor via cannula, causing the contents of the reactor to turn a deep ruby red color. The contents of the reactor were stirred for 10 minutes. Methyl methacrylate (11.53 g) in cyclohexane (5.31 g) was then ...

Embodiment 3

[0059] Embodiment 3: prepare PMMA-b-PTMSMMA diblock copolymer

[0060]In a 500 mL 3 neck round bottom reactor under argon atmosphere was added tetrahydrofuran ("THF") (142 g). The THF was then cooled to -78°C in the reactor. A 0.36M solution of sec-butyllithium in cyclohexane was then titrated into the reactor contents until the reactor contents exhibited a solid pale yellow color. The contents of the reactor were then warmed and held at 30°C until the color of the material disappeared completely (approximately 10-15 minutes). 1,1-Diphenylethylene (0.086 g) diluted in cyclohexane (1.63 g) was then cannulated into the reactor. The reactor contents were then cooled to -78°C. Sec-butyllithium (4.5 g) diluted at 0.065 M in cyclohexane was then added rapidly to the reactor via cannula, causing the contents of the reactor to turn a deep ruby red color. The contents of the reactor were stirred for 21 minutes. Methyl methacrylate (11.5 g) in cyclohexane (17.81 g) was then can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com