Preparation method for reactive polyurethane hot melt composition and applications thereof

A polyurethane hot-melt adhesive, reactive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of difficult disassembly, easily damaged parts, etc., and achieves convenient use and recycling. The effect of reuse and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of sample in the embodiment:

[0056] The preparation method of the composition described in embodiment 1 to embodiment 13 is a one-step method, as follows:

[0057] Add all polyester polyols, polyether polyols and thermoplastic polymer resins to the reactor equipped with gas inlet and outlet joints, thermometers, stirrers, heating systems and vacuum systems, heat and stir and melt under vacuum and mix and dehydrate To obtain a homogeneous mixture with a moisture content of less than 0.05% by mass, then add polyisocyanate to carry out polymerization reaction, the polymerization reaction is carried out under the protection of dry inert gas, and accompanied by proper stirring and mixing, until the reaction is completed, to obtain the reaction Type polyurethane hot melt adhesive composition. Then the obtained reactive polyurethane hot-melt adhesive composition is placed in a container, and the inner space of the container is protected with dry nitro...

Embodiment 14

[0058] The preparation method of the composition described in embodiment 14 is a two-step method, as follows:

[0059] The first step: Synthesis of diisocyanate group-terminated prepolymer compound 1

[0060] Add 800g of polyether diol (hydroxyl value 110mgKOH / g) to the reactor equipped with gas inlet and outlet joints, thermometer, stirrer, heating system and vacuum system, heat, stir and vacuumize to remove water until the moisture content is lower than 250ppm, add 590g of 4,4'-MDI into the reactor according to the ratio of NCO / OH of 3:1, carry out the polymerization reaction under the protection of heating, stirring and dry inert gas, and measure the content of isocyanate group during the reaction. When the content of isocyanate groups decreases continuously and finally reaches a stable value, the unreacted monomer 4,4'-MDI in the reactor is distilled off by vacuuming, and the -NCO content is measured by sampling during the process until the -NCO content reaches a stable va...

Embodiment 15

[0064] The first step: Synthesis of diisocyanate group-terminated prepolymer compound 2

[0065] The method is the same as the first step in Example 14, except that 800 g of polyester diol (hydroxyl value: 110 mgKOH / g) is used instead of polyether diol.

[0066] Step 2: Synthesis of Hot Melt Adhesive Composition

[0067] The prepolymer compound 2 was used to replace the prepolymer compound 1, and the others were combined according to the formula of this example to synthesize a composition.

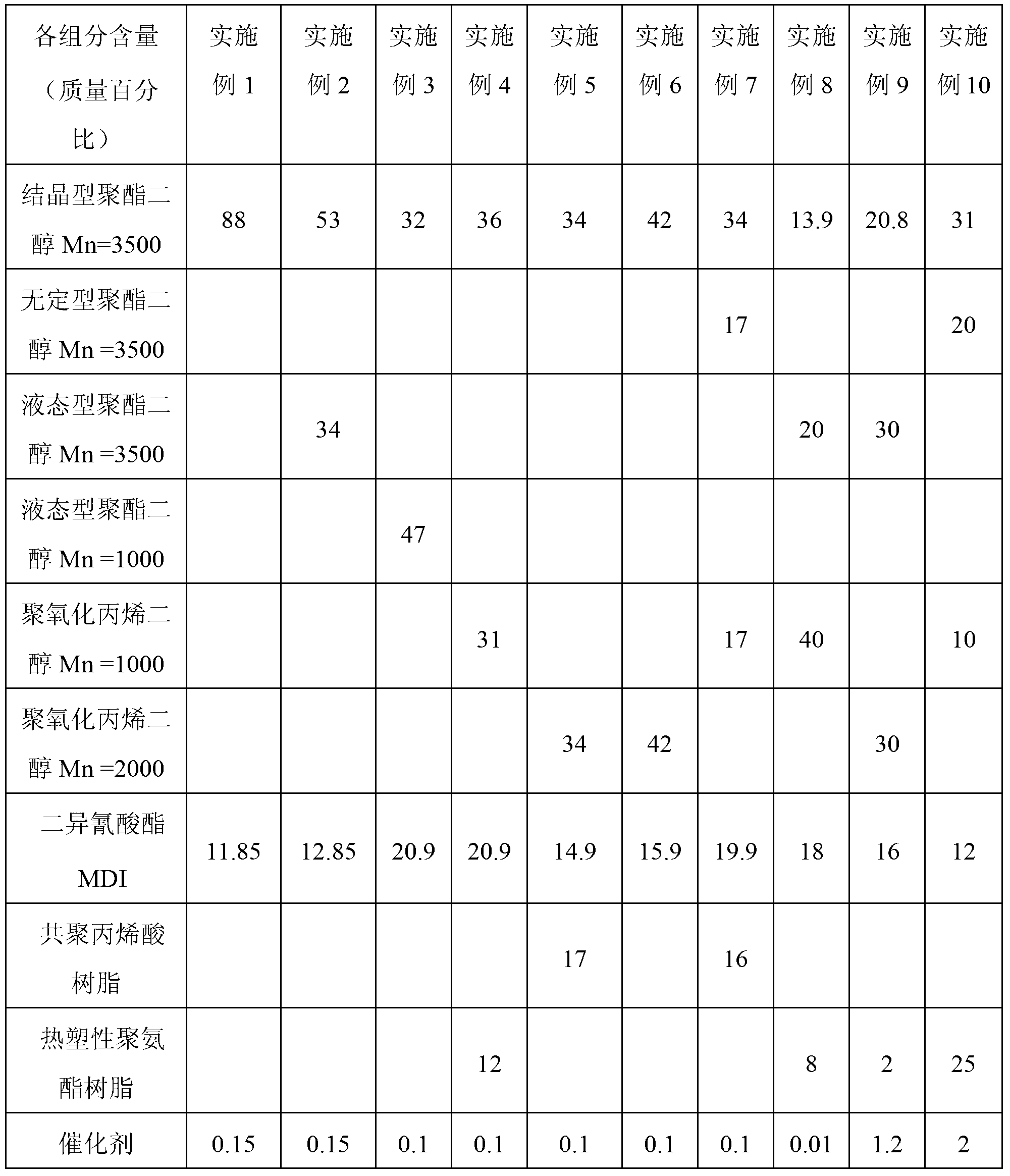

[0068] Table 1 is synthesized and has reactive polyurethane hot-melt adhesive composition formula

[0069]

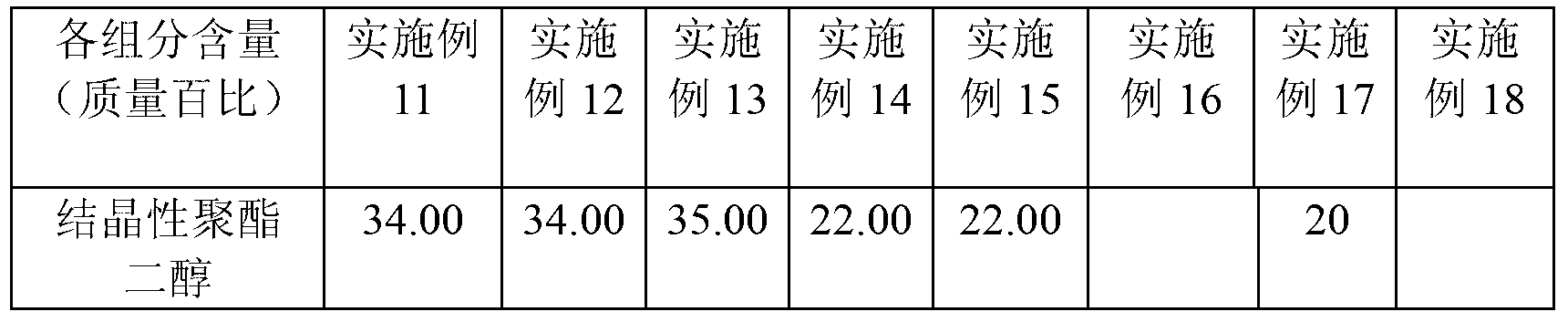

[0070] Table 2 synthesis has reactive polyurethane hot-melt adhesive composition formula

[0071]

[0072]

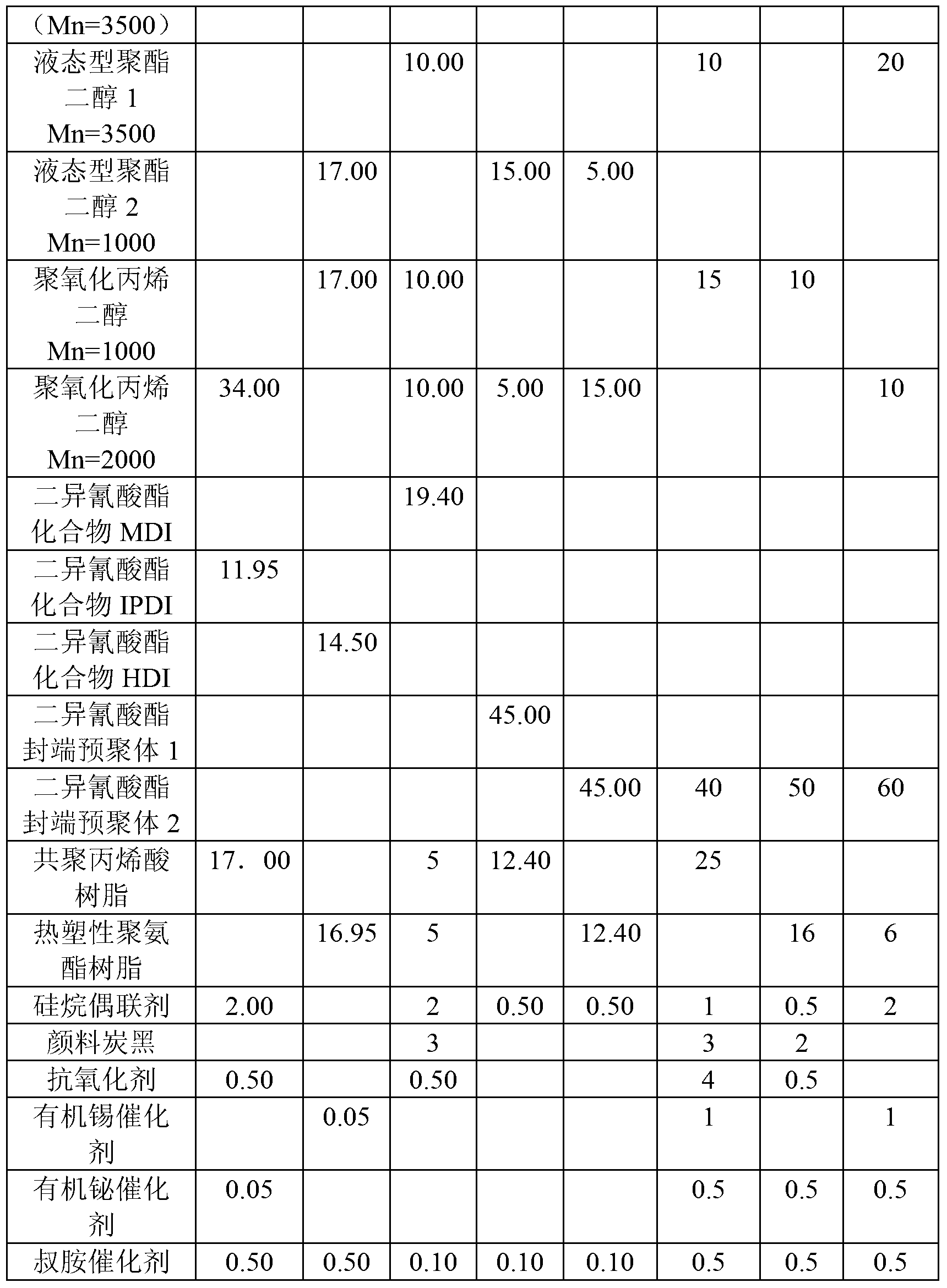

[0073] Table 3 The changes in the bonding strength of each embodiment composition at different temperatures

[0074]

[0075]

[0076] Table 1 and Table 2 are the formulas for synthesizing reactive polyurethane hot melt adhesive compositions. From the test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com