Preparation method of graphene lubricating grease

A technology of olefin grease and grease, which is applied in the field of preparation of graphene grease, can solve the problems of poor mixing uniformity, high addition amount, and low utilization rate, and achieve the effect of reducing friction and wear and improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

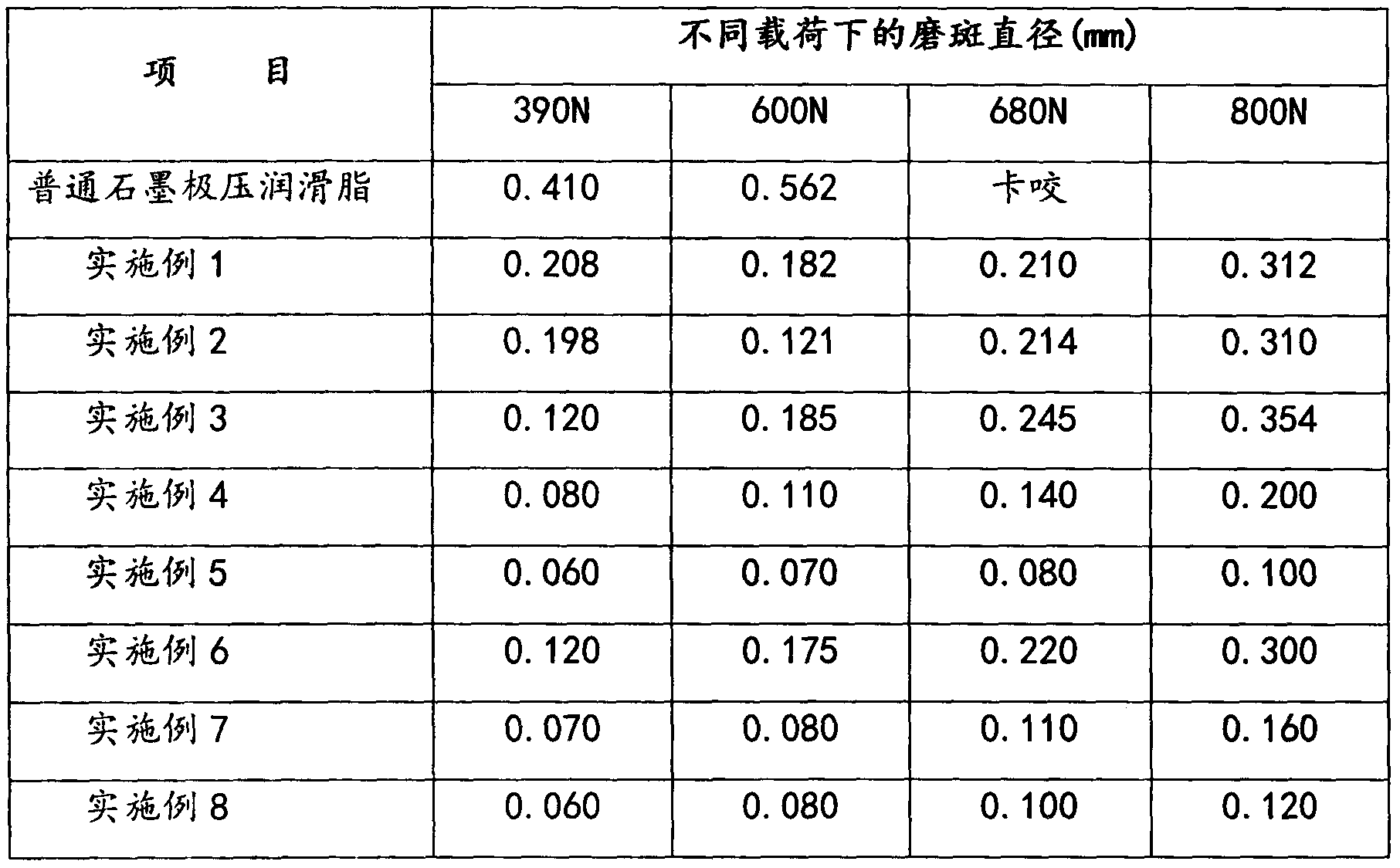

Examples

Embodiment 1

[0020] Add 1g of graphene to a solvent containing 0.02g of silicon-based coupling agent, treat it at a temperature of 60°C for 3h, filter and dry to obtain modified graphene powder; preheat the base oil of the grease, and then add the hydroxyl Stearic acid, calcium hydroxide aqueous solution and 0.1% of the above modified graphene are saponified at 105-110°C for 3 hours, then heated to 200-220°C for dehydration, quenched to a temperature of 150-170°C, then sheared, homogenized and combined After degassing, a graphene-based calcium-based grease is prepared.

Embodiment 2

[0022] 1g of graphene was added to a solvent containing 0.005g of titanium-based coupling agent, treated at a temperature of 30°C for 3h, filtered and dried to obtain modified graphene powder. Preheat the base oil of the grease, then add hydroxystearic acid and calcium acetate complex fatty acid calcium, saponify at 105-110°C for 3 hours, heat up to 200-220°C for dehydration, quench to 150-170°C, add 0.05% The modified graphene described above is then sheared, homogenized and degassed to obtain a graphene-based composite calcium grease.

Embodiment 3

[0024] 1g of graphene was added to a solvent containing 0.01g of aluminum-based coupling agent, treated at a temperature of 40°C for 8h, filtered and dried to obtain modified graphene powder. Preheat the base oil of the grease, then add hydroxystearic acid, sodium hydroxide aqueous solution, saponify at 105-110°C for 3 hours, add 0.004% of the above modified graphene, heat up to 200-220°C for dehydration, and then quench to The temperature is 150-170℃, and then shearing, homogenizing and degassing, to obtain graphene-based sodium-based grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com