Ion sensitive sensor and manufacturing method thereof

The technology of an ion-sensitive sensor and a manufacturing method is applied in the field of graphene ion-sensitive sensor based on a field-effect transistor structure and its preparation field, which can solve problems such as difficult industrial production, few detection samples, and poor selectivity, and achieve short response time, The effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

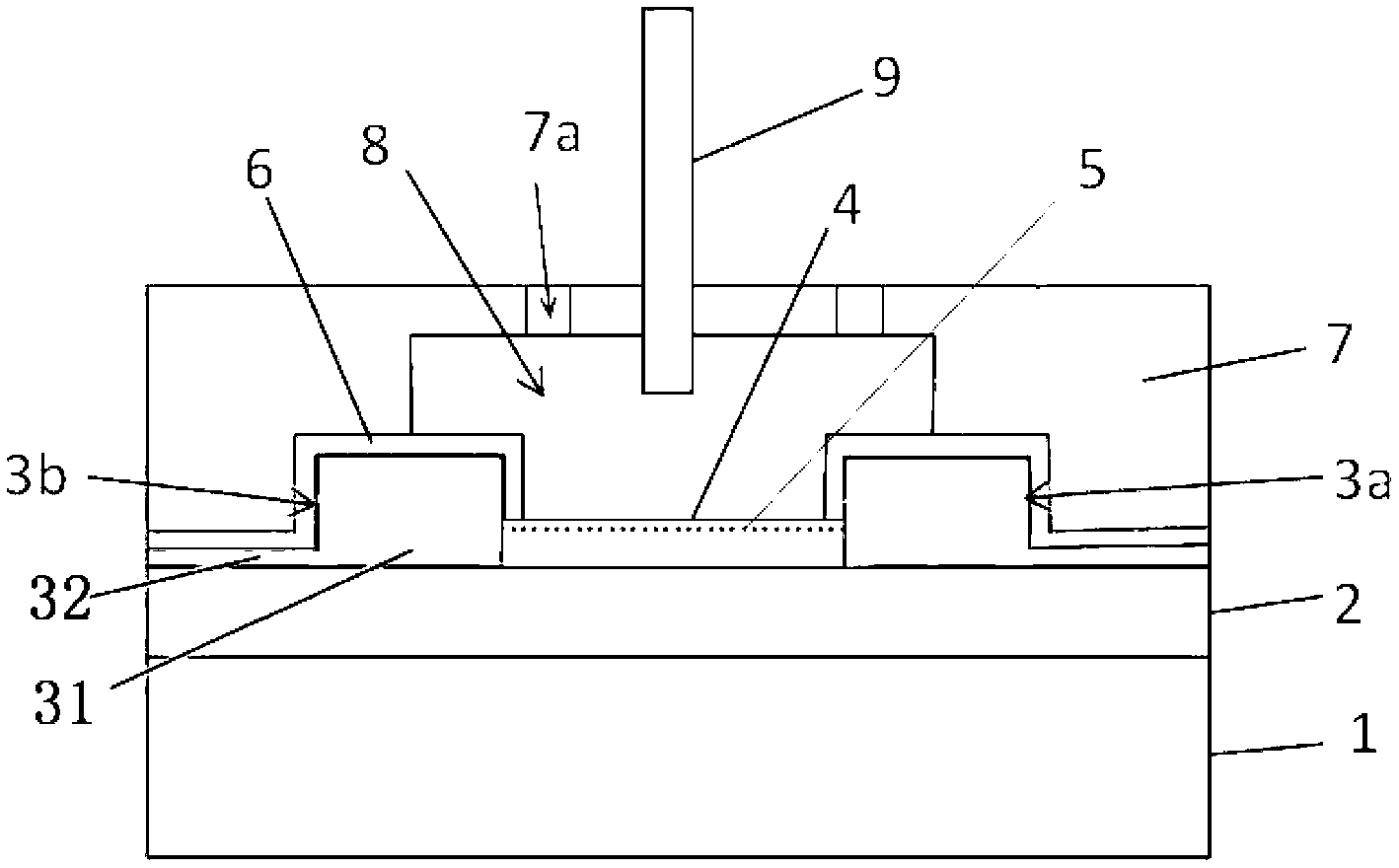

[0037] Such as figure 1 Shown, the graphene ion sensitive sensor of the present embodiment comprises:

[0038] stacking silicon oxide layer 2 and silicon substrate 1 up and down;

[0039] The source electrode 3a and the drain electrode 3b arranged on the silicon oxide layer 2 at intervals; the source electrode 3a and the drain electrode 3b each include a plug-in portion 31 and a socket for electrical connection with an external circuit (not shown in the figure). extension 32;

[0040] The graphene layer 4 arranged on the surface of the silicon oxide layer 2 between the source electrode 3a and the drain electrode 3b, the graphene layer 4 is respectively connected to the source electrode 3a inserting portion 31 and the drain electrode 3b inserting portion 31 connection; the surface layer of the graphene layer 4 is permeated with metal oxide particles 5;

[0041] An insulating layer 6 covering the surfaces of the source electrode 3a and the drain electrode 3b.

[0042] The mi...

Embodiment 2

[0067] The structure of the graphene ion-sensitive sensor of this embodiment is the same as that of Embodiment 1. The difference is that the source and drain are made of Pt, and the insulating layer is made of photoresist AZ4602.

[0068] Moreover, in this embodiment, a graphene solution with a concentration of 0.1 mg / mL is printed between the source electrode and the drain electrode by an aerosol printing method. Then place the chip in 1mol / L NiCl 2 , 0.2mol / L NH 4 Cl and 0.06875mol / L NaOH mixed solution, placed in a constant temperature oven at 55°C for 40min. Then place the chip under the protection of Ar gas for annealing at 350° C. for 120 minutes, and keep it warm for 2 hours.

[0069] The remaining steps can be shown in Example 1 with reference to.

Embodiment 3

[0071] The structure of the graphene ion-sensitive sensor of this embodiment is the same as that of Embodiment 1. The difference is that the source and drain are made of Pt, and the insulating layer is made of polymethyl methacrylate.

[0072] Moreover, in this embodiment, a graphene solution with a concentration of 0.05 mg / mL is printed between the source electrode and the drain electrode by means of aerosol printing. Then place the chip in 1mol / L NiCl 2 , 0.2mol / L NH 4 Cl and 0.06875mol / L NaOH mixed solution, placed in a constant temperature oven at 55°C for 30min. Then place the chip under the protection of Ar gas for annealing at 350° C. for 30 minutes, and keep it warm for 2 hours.

[0073] The remaining steps can be shown in Example 1 with reference to.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com