Metallic oxide thin film transistor and manufacturing method thereof

An oxide thin film and oxide semiconductor technology, applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as increasing cost and difficulty of preparation process, reducing device aperture ratio, and affecting the performance of metal oxide semiconductors. , to achieve better display effect, large source-drain current, and improved carrier mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

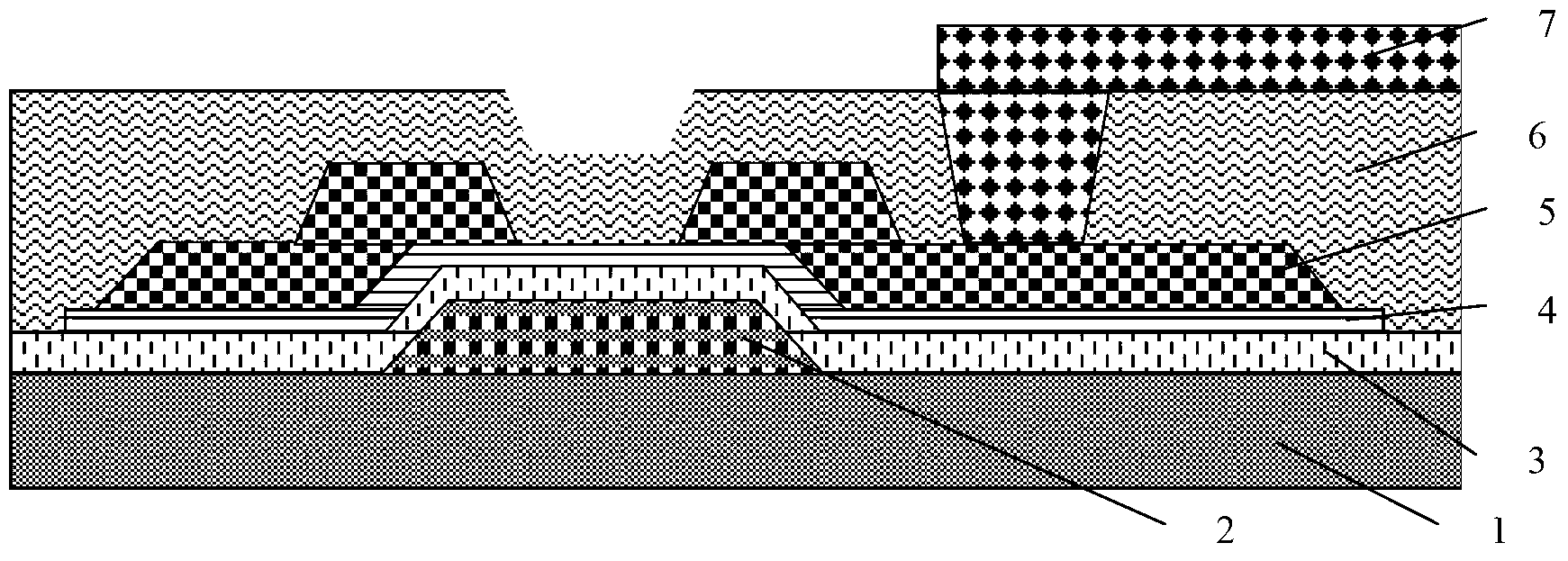

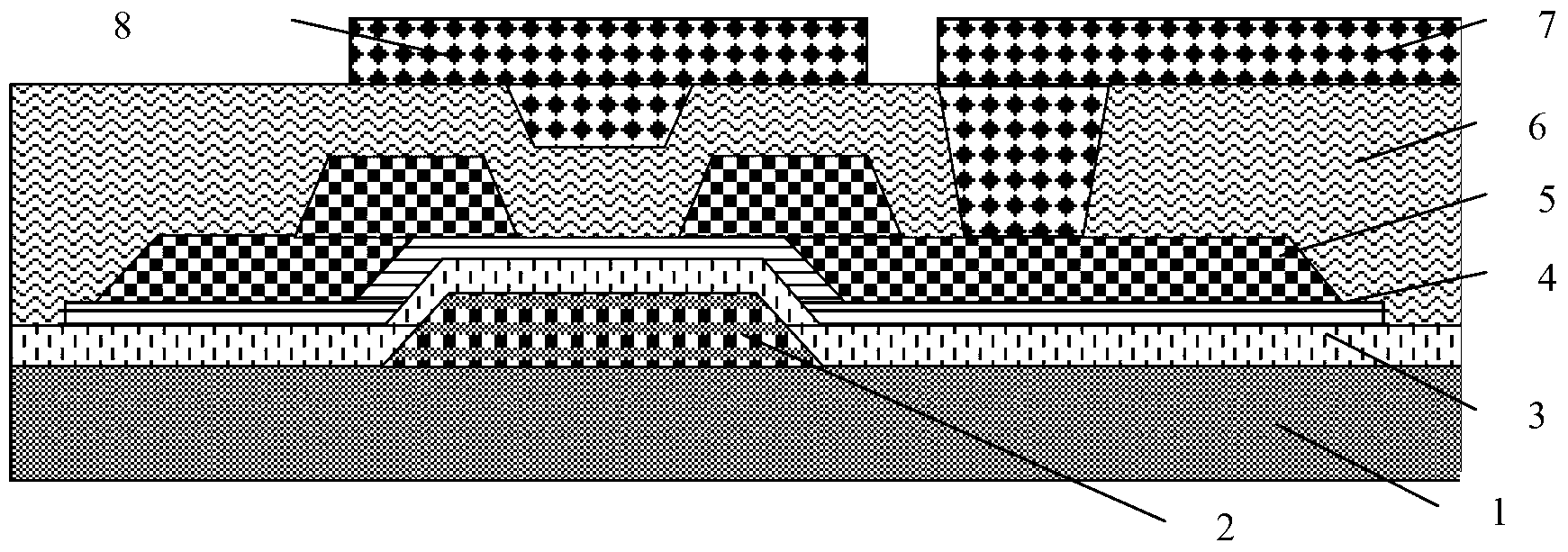

[0054] This embodiment provides a metal oxide thin film transistor, such as figure 2 As shown, it includes a substrate 1, and a gate 2, a gate insulating layer 3, a metal semiconductor oxide layer 4, a source / drain conductive layer 5, and an interlayer insulating layer 6 arranged in sequence along a direction away from the substrate 1, The interlayer insulating layer 6 fills the gap between the source conductive layer and the drain conductive layer to form a channel layer; an anode conductive layer 7 and a conductive upper gate 8 are formed on the upper surface of the interlayer insulating layer 6; The upper gate 8 completely covers the channel layer, and the light reflectance of its material is greater than 85%.

[0055] This embodiment also provides a method for preparing the above-mentioned metal oxide thin film transistor, such as Figure 3A to Figure 3F shown, including the following steps:

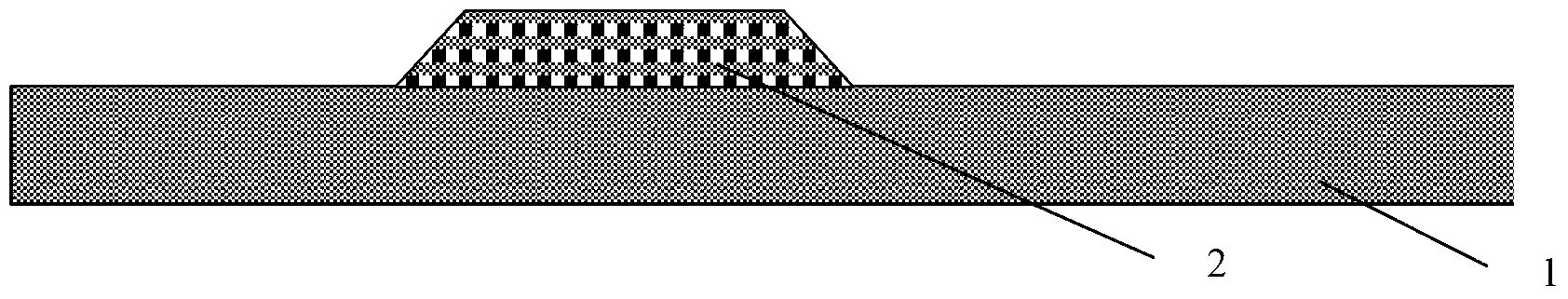

[0056] S1. On the substrate 1, the gate 2, the gate insulating layer 3, the m...

Embodiment 2

[0068] In this embodiment, as a further improvement of Embodiment 1, the work function of the material of the upper grid 8 is between 4.9ev-5.2ev; more preferably, the surface resistance of the material of the upper grid 8 is less than 10Ω / □.

[0069] In the prior art, there are many materials that meet the above conditions. Considering the relatively mature materials used in OLED devices, the material of the upper gate 8 includes any one of the following groups of materials: ITO / Ag / ITO, ITO / Ag, ITO / Al / ITO, ITO / Al. The above materials are only preferred embodiments of this application, and other qualified materials can also be selected.

Embodiment 3

[0071] In order to make the manufacturing process of the metal oxide semiconductor thin film transistor simpler, the anode conductive layer 7 is made of the same material as the upper gate 8 .

[0072] In the method for preparing the metal oxide thin film transistor, the step S2 also includes the following steps:

[0073] S2_1. Photoetching an anode contact hole pattern on the interlayer insulating layer 6, and etching to obtain an anode contact hole, the anode contact hole penetrates the interlayer insulating layer 6 and communicates with the metal oxide semiconductor layer 4;

[0074] S2_2. Deposit a layer of anode conductive material on the interlayer insulating layer 6, the anode conductive material fills the anode contact hole and contacts the metal oxide semiconductor layer 4; the method for depositing the anode conductive material includes: Physical vapor deposition method, evaporation method and other deposition methods, etc.;

[0075] S2_3, photoetching an upper grid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com