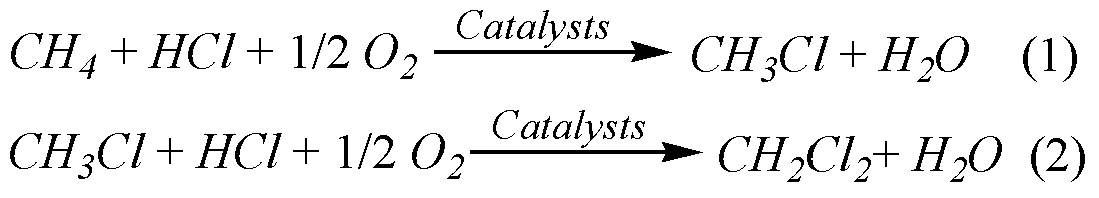

Cerium-based catalyst for producing chloromethane by catalyzing oxidization reaction of methane chloride and preparation method thereof

A technology of methane chlorination and cerium-based catalysts, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of halogenated hydrocarbons, etc., and can solve the problems of high cost and large energy consumption. Achieve the effect of simple preparation method and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

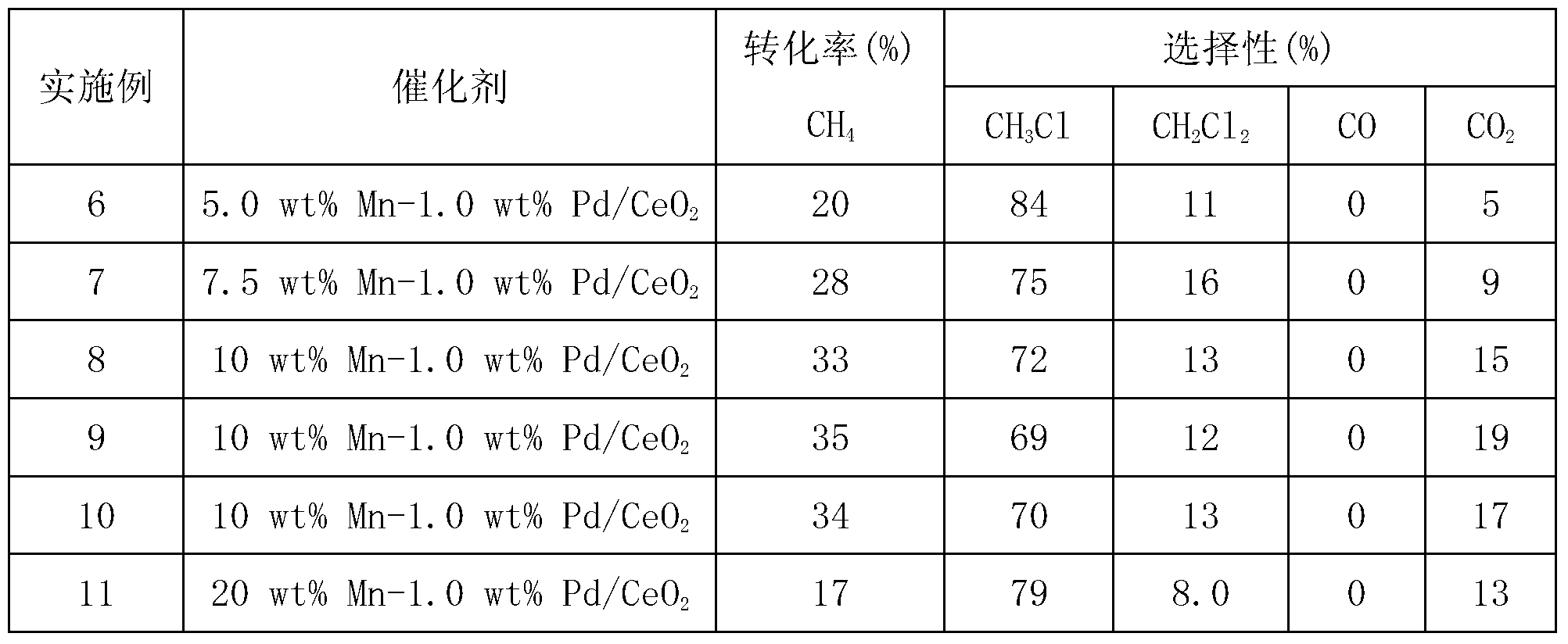

Examples

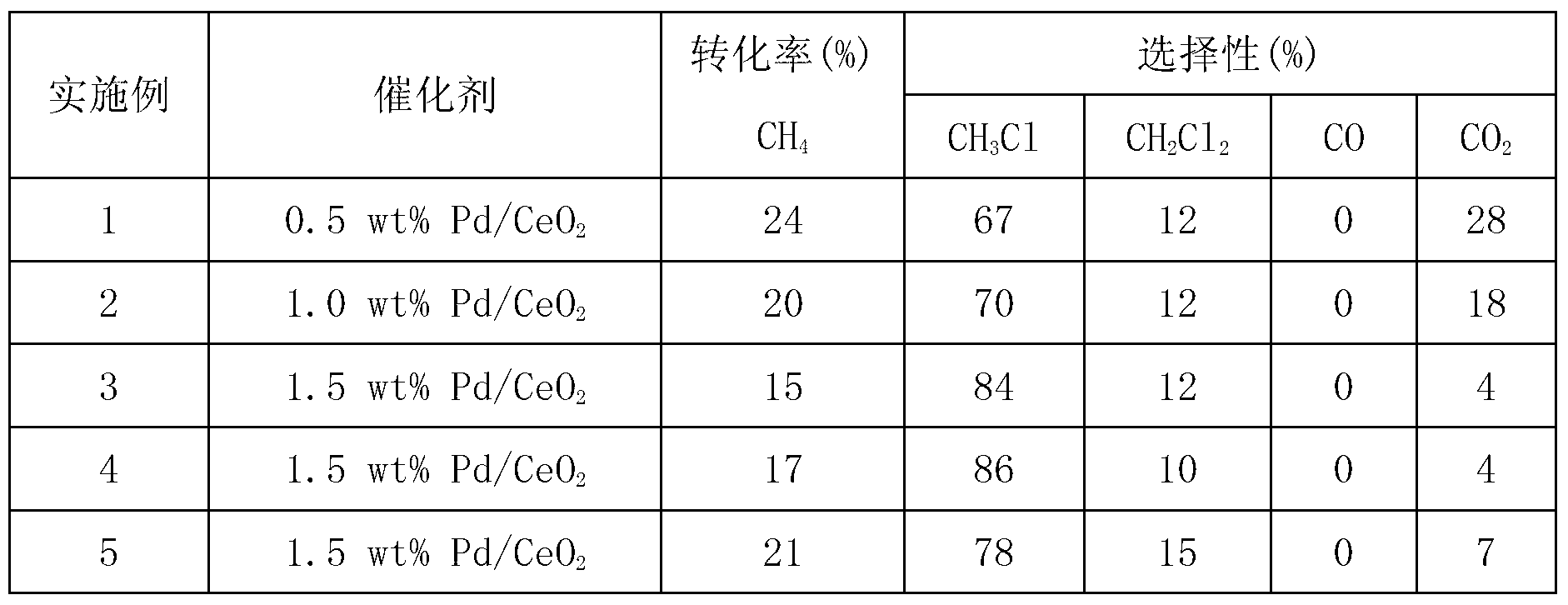

Embodiment 1

[0031] Catalyst preparation:

[0032] (1)CeO 2 Preparation of:

[0033] 3.47g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of deionized water, and 140mL of 9M NaOH solution was added under stirring, then transferred to an autoclave for 24 hours at 100°C, cooled, filtered with suction, washed, washed and filtered three times, and finally dried at 100°C for 5 hours, 550°C ℃ calcination for 6h to produce CeO 2 .

[0034] (2) 0.5wt%Pd / CeO 2 Catalyst preparation:

[0035] Mix 1.70 mL of 0.006 g / mL (calculated as Pd) palladium chloride solution in 20 mL of deionized water, and add 2.0 g of the CeO prepared above under stirring. 2 , after stirring continuously for 12h, evaporated to dryness in 80°C water bath, dried at 100°C for 5h, and calcined at 550°C for 6h to obtain 0.5wt%Pd / CeO 2 catalyst.

[0036] Catalyst Test:

[0037] The reaction was carried out in a fixed-bed flow reactor at normal pressure. The reactor was a quartz glass tube with an inner diameter of 10 mm. The ...

Embodiment 2

[0039] Catalyst preparation:

[0040] The operating process was carried out as in Example 1, and the consumption of the palladium chloride solution was changed to 3.30 mL. The obtained catalyst is 1.0wt%Pd / CeO 2 catalyst.

[0041] Catalyst Test:

[0042] According to the test conditions in Example 1, the activity evaluation results of Example 2 are listed in Table 1.

Embodiment 3

[0044] Catalyst preparation:

[0045] The operation process is carried out according to Example 1, and the consumption of palladium chloride solution is changed to 5.00mL. The resulting catalyst is 1.5wt%Pd / CeO 2 catalyst.

[0046] Catalyst Test:

[0047] According to the test conditions in Example 1, the activity evaluation results of Example 3 are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com