Kelp extracting solution steel bar corrosion inhibitor and application thereof

The invention relates to a technology for a steel bar rust inhibitor and an extracting solution, which is applied in the field of building materials, and can solve the problems of the rust inhibitor polluting the environment, large environmental pollution, and heavy environmental load, and achieves the effects of low price, simple preparation process and natural source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

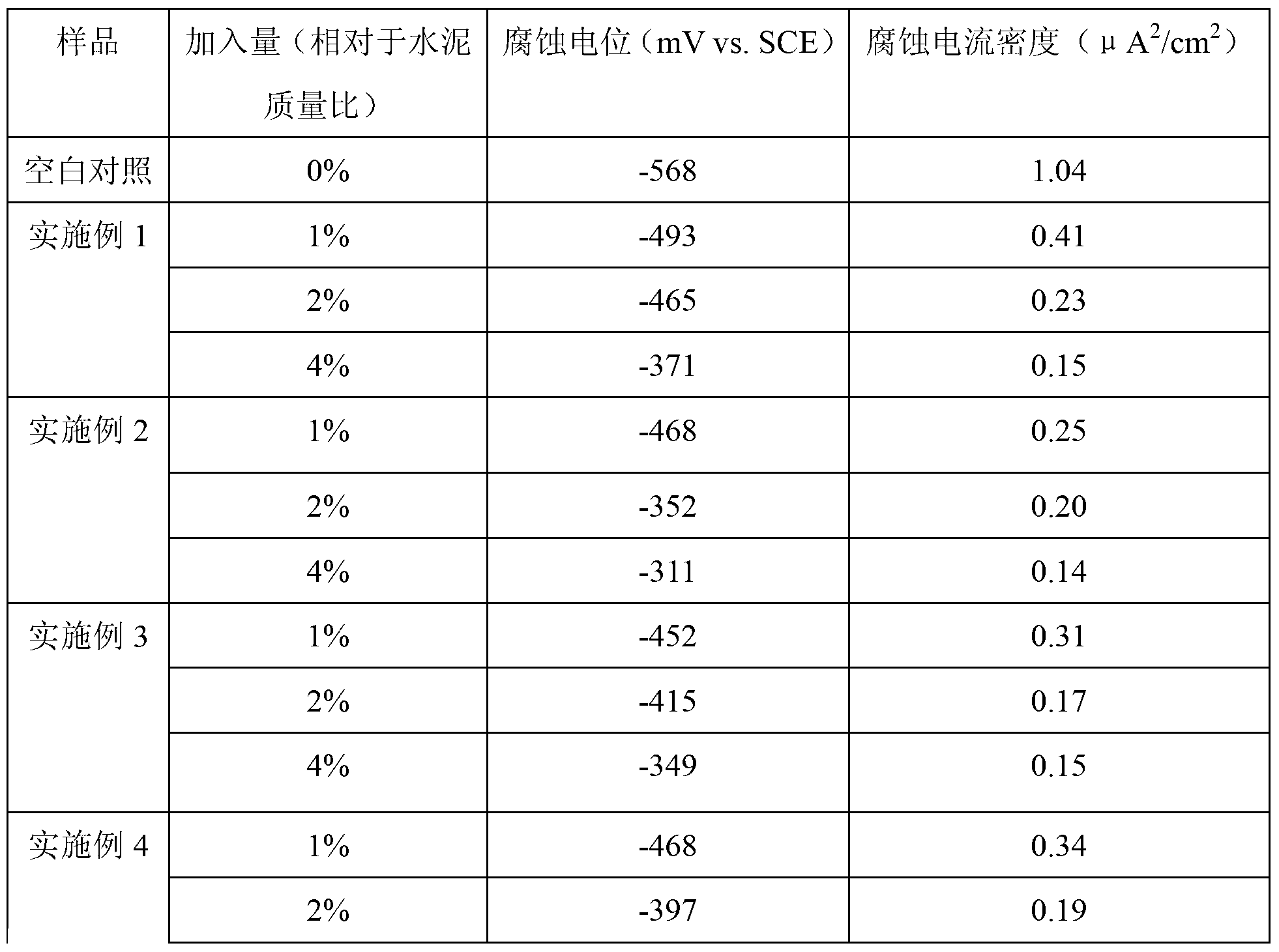

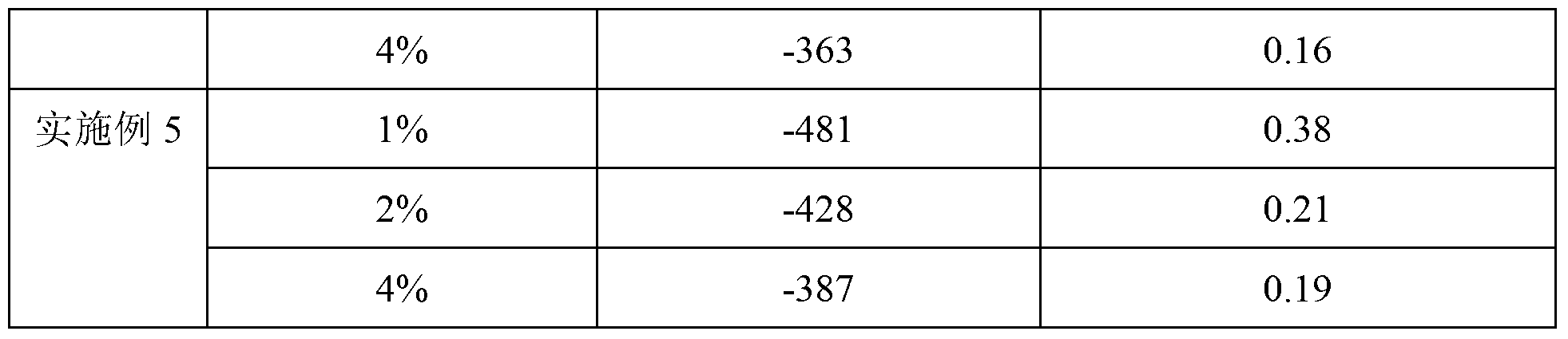

Examples

Embodiment 1

[0019] The kelp extract liquid steel rust inhibitor is prepared by the following method: wash the kelp with clean water, dry it in an oven at a constant temperature of 60°C, pulverize it with a plant grinder, and sieve it with a 0.63 sieve to obtain dry kelp powder. Weigh kelp powder, dissolve it in 0.1mol / L sodium hydroxide solution according to the mass ratio of 0.6%, stir evenly, let it stand at 20°C for 24 hours, filter to remove the sediment, adjust the pH value of the extract with nitric acid, so that the pH is at 12.5 or so, that is, steel rust inhibitor.

Embodiment 2

[0021] The kelp extract liquid steel rust inhibitor is prepared by the following method: wash the kelp with clean water, dry it in an oven at a constant temperature of 60°C, pulverize it with a plant grinder, and sieve it with a 0.63 sieve to obtain dry kelp powder. Weigh kelp powder, dissolve it in 0.1mol / L sodium hydroxide solution according to the mass ratio of 0.3%, stir evenly, let it stand at 40°C for 36h, filter to remove the sediment, adjust the pH value of the extract with nitric acid, so that the pH is 9.0, that is, steel bar rust inhibitor.

Embodiment 3

[0023] The kelp extract liquid steel rust inhibitor is prepared by the following method: wash the kelp with clean water, dry it in an oven at a constant temperature of 60°C, pulverize it with a plant grinder, and sieve it with a 0.63 sieve to obtain dry kelp powder. Weigh kelp powder, dissolve it in 0.1mol / L sodium hydroxide solution according to the mass ratio of 1.2%, stir evenly, let it stand at 10°C for 8 hours, filter to remove the sediment, adjust the pH value of the extract with nitric acid, so that the pH is 11.0, namely steel bar rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com