Preparation method of high purity cyclopentene

A cyclopentene and high-purity technology, which is applied in the field of preparation of high-purity cyclopentene, can solve the problems of high energy consumption in the production process and low purity of cyclopentene, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

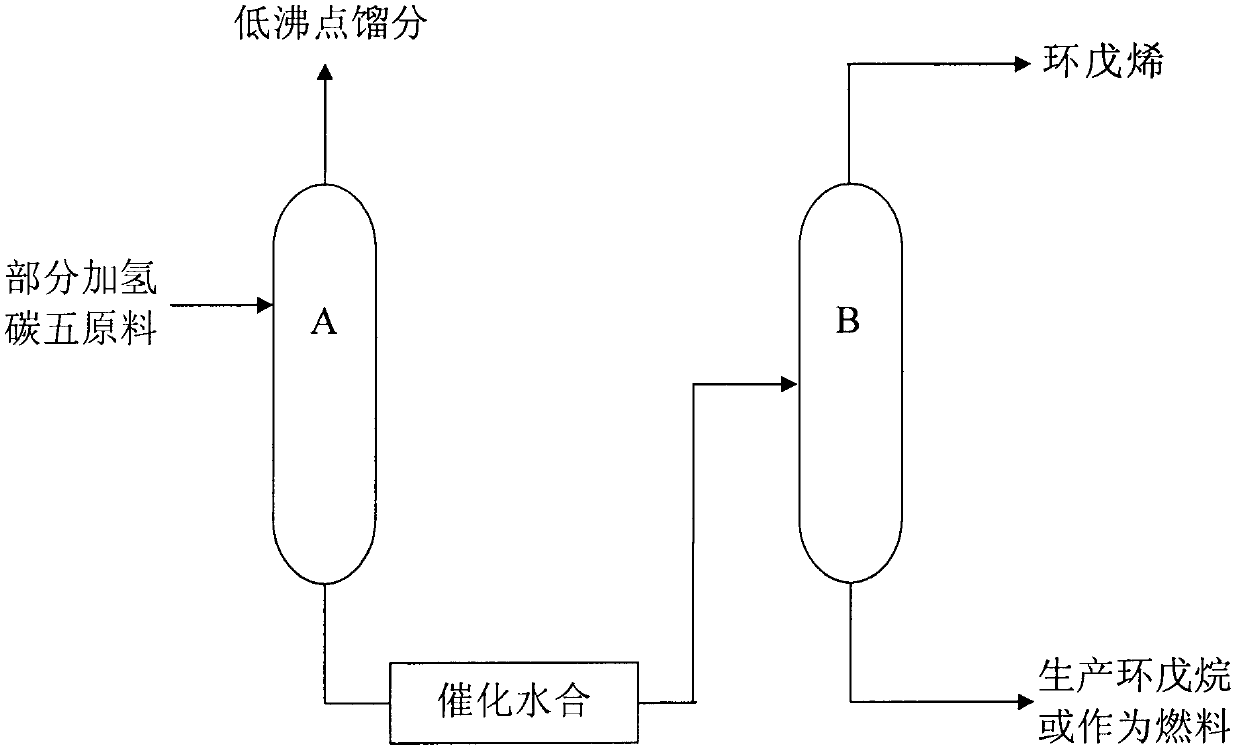

[0024] Examples, see figure 1 Shown:

[0025] The partly hydrogenated C5 fraction whose composition is shown in Table 1 is rectified in the rectifying tower A. The rectification tower A is a packed tower with a theoretical plate number of 90-110. Partially hydrogenated C5 fraction is fed from the fiftieth plate of rectification tower A when it is preheated to 45-55°C. The temperature at the top is 45-55°C, the reflux ratio is 8-15, the low-boiling fraction with a mass percentage of 71% is extracted from the top of the tower, and the cyclic hydrocarbon fraction with a mass percentage of 21% is discharged from the bottom of the tower. In this step, light components with a boiling point lower than 38.57°C (2-methyl-2-butene boiling point) are separated from the top of the rectification tower A, while light compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com