Production method for extracting and purifying hyaluronic acid

A hyaluronic acid and production method technology, applied in the field of microorganisms and biological products, can solve problems such as low product yield, long process lines, and high labor intensity, and achieve the goals of shortening process lines, reducing production costs, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

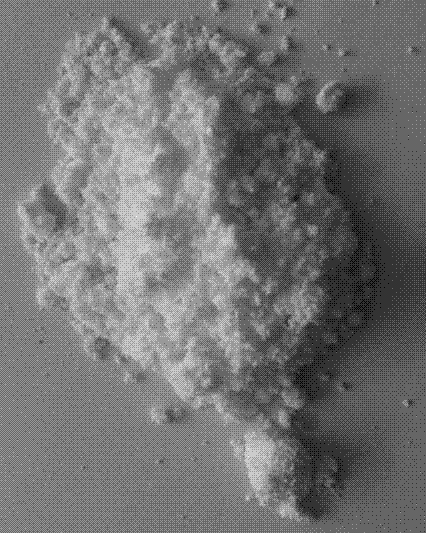

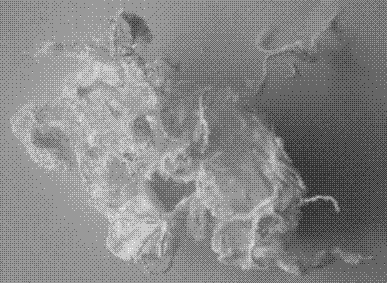

Image

Examples

Embodiment 1

[0037] Fermentation broth inactivation: put the fermentation broth into the first fermentation tank, stir, and the stirring speed is 60 rpm, then add trichloroacetic acid to the first fermentation tank, adjust the pH value of the fermentation broth to 4.0, stir for 60min, The enzyme in the fermentation broth is inactivated, and the acidic protein in it reaches the isoelectric point to aggregate and precipitate, and the inactivated fermentation broth is obtained. In this step, using trichloroacetic acid to adjust the pH value of the fermentation broth can inactivate the fermentation broth and precipitate acidic proteins.

[0038] Primary alcohol precipitation: transfer the inactivated fermentation broth to the first settling tank, slowly add 95% ethanol twice the volume of the inactivated fermentation broth to the first settling tank, and turn on the air flotation device in the first settling tank , while stirring for 30-60min.

[0039] Coarse separation: after the stirring is...

Embodiment 2

[0051] Fermentation broth inactivation: put the fermentation broth into the first fermenter, stir, and the stirring speed is 40 rpm, then add trichloroacetic acid to the first fermenter, adjust the pH value of the fermented broth to 4.5, stir for 80min, The enzyme in the fermentation broth is inactivated, and the acidic protein in it reaches the isoelectric point to aggregate and precipitate, and the inactivated fermentation broth is obtained.

[0052] Primary alcohol precipitation: transfer the inactivated fermentation broth to the first settling tank, slowly add 2.2 times the volume of inactivated fermentation broth with 95% ethanol to the first settling tank, and turn on the air flotation device in the first settling tank , while stirring for 50min.

[0053] Coarse separation: after the stirring is completed, collect the crude hyaluronic acid product floating in the inactivated fermentation broth and the crude hyaluronic acid product at the bottom of the first settling tank...

Embodiment 3

[0062] Fermentation broth inactivation: put the fermentation broth into the first fermentation tank, stir, and the stirring speed is 100 rpm, then add trichloroacetic acid to the first fermentation tank, adjust the pH value of the fermentation broth to 4.0, stir for 30min, The enzyme in the fermentation broth is inactivated, and the acidic protein in it reaches the isoelectric point to aggregate and precipitate, and the inactivated fermentation broth is obtained.

[0063] Primary alcohol precipitation: transfer the inactivated fermentation broth to the first settling tank, slowly add 2.5 times the volume of inactivated fermentation broth with 95% ethanol to the first settling tank, and turn on the air flotation device in the first settling tank , while stirring for 30min.

[0064] Coarse separation: after the stirring is completed, collect the crude hyaluronic acid product floating in the inactivated fermentation broth and the crude hyaluronic acid product at the bottom of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com