A kind of refining method of lignin

A refining method and lignin technology, applied in the field of comprehensive utilization of biomass, can solve the problems of inability to obtain pure lignin products, high equipment requirements, long dissolution time, etc., and achieve the effects of low cost, high economic value and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

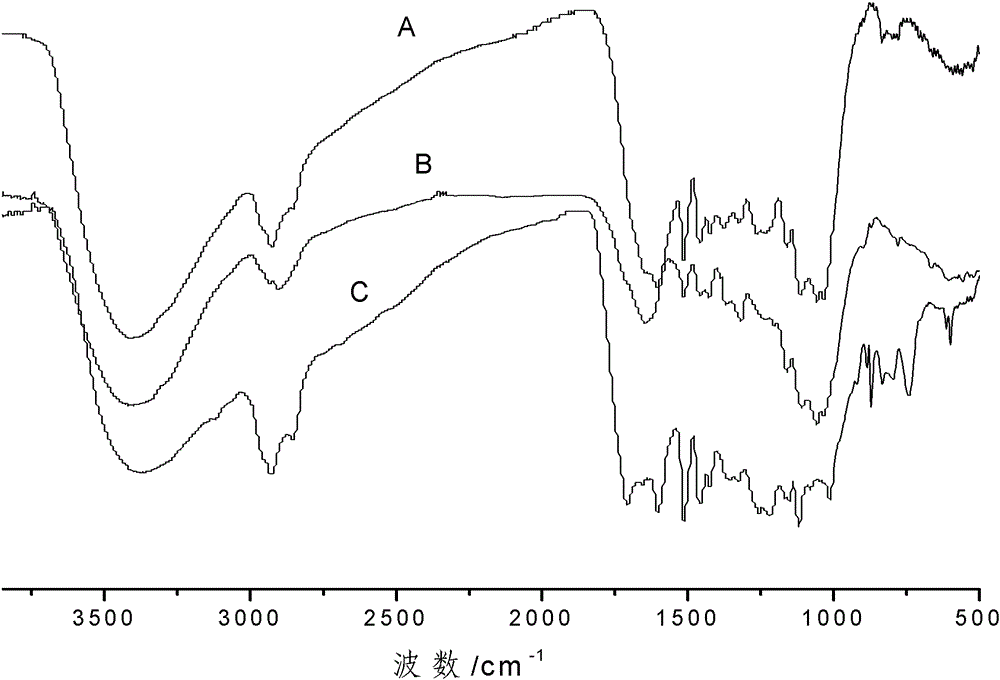

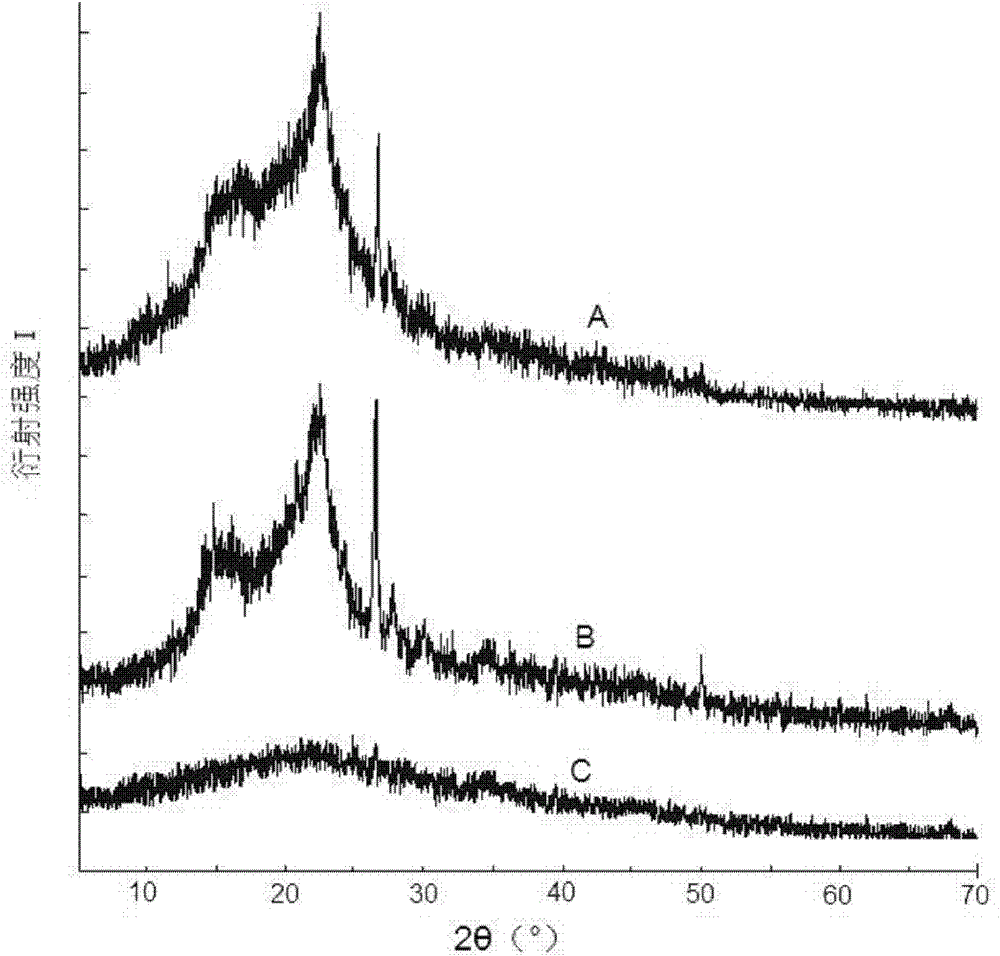

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: Add enzymatic lignin raw material and liquefaction reagent furfuryl alcohol into the reactor at a mass ratio of 1:3, liquefy and dissolve at 120°C for 15 minutes, cool to 25°C after liquefaction, then filter to remove the residue, and put The filtrate is distilled to recover the solvent to obtain refined lignin.

[0017] The lignin yield obtained in this embodiment is 43%, which shows that the lignin refining method has high efficiency.

specific Embodiment approach 2

[0018] Specific embodiment two: Add enzymatic lignin raw material and liquefaction reagent furfuryl alcohol into the reactor at a mass ratio of 1:5, liquefy and dissolve at 140°C for 30 minutes, cool to 80°C after liquefaction, then filter to remove the residue, and put The filtrate is distilled to recover the solvent to obtain refined lignin.

[0019] The yield of lignin obtained in this embodiment is 48%, which shows that the lignin preparation method has high efficiency.

specific Embodiment approach 3

[0020] Specific embodiment three: Add the enzymatic lignin raw material and liquefaction reagent furfuryl alcohol into the reactor at a mass ratio of 1:4, liquefy and dissolve at 170°C for 90 minutes, cool to 20°C after liquefaction, then filter to remove the residue, and put The filtrate is distilled to recover the solvent to obtain refined lignin.

[0021] The yield of lignin obtained in this embodiment is 49%, which shows that the lignin preparation method has high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com