Method for preparing liquid fuel through coliquefaction of coal and alage

A technology of liquid fuel and co-liquefaction, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of unsatisfactory bio-oil quality, low yield of liquid fuel oil, poor mass transfer and heat transfer effect, etc., and achieves good industrialization. Application prospect, unique performance, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

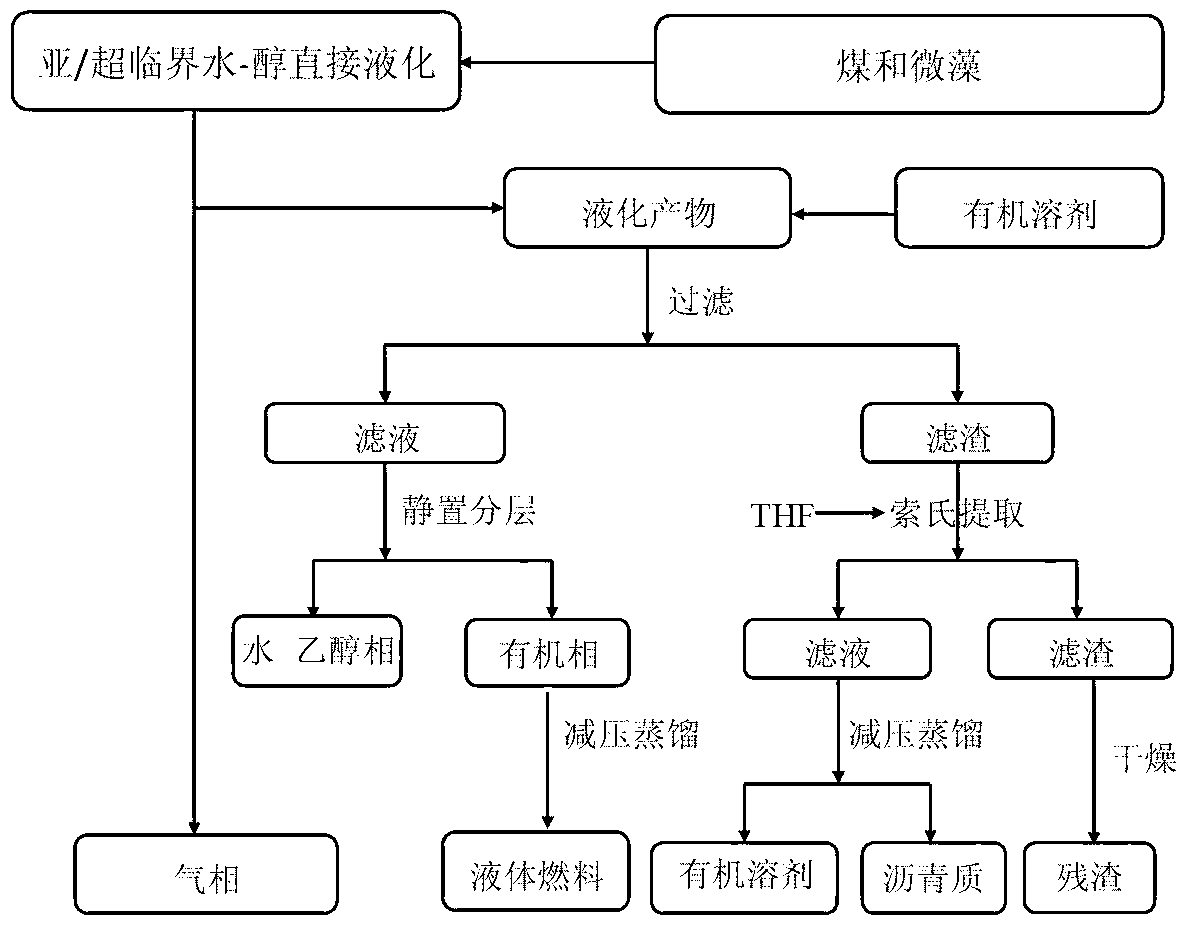

Method used

Image

Examples

Embodiment 1

[0025] According to the solid-liquid ratio of 1:10 (g / mL), 4.00 g of sample (Dunaliella salina was selected as algae, accounting for 50 wt.%, lignite as coal) and 40 mL of water-methanol mixture were added to the reaction kettle. The volume percentage of methanol in the water-alcohol mixture medium is 60%, the liquefaction temperature is 340°C, the pressure is 29.00MPa, and the reaction time is 30min. The liquefaction rate of the obtained coal and algae is 63.00%, and the oil production rate is 30.92%.

Embodiment 2

[0027] Weigh 6.00g of sample according to the ratio of solid to liquid 1.5:10 (g / mL) (select spirulina for algae, the percentage is 50 wt.%, choose lignite for coal) and add 40mL of water-isopropanol mixture into the reaction kettle , the volume percentage of isopropanol in the water-alcohol mixture medium is 40%, the liquefaction temperature is 320°C; the pressure is 26.00MPa; the reaction time is 30min, the liquefaction rate of the obtained coal and algae is 63.01%, and the oil production rate is 25.93%.

Embodiment 3

[0029]According to the solid-liquid ratio of 1:10 (g / mL), 4.00 g of sample (Dunaliella salina was selected as algae, accounting for 50 wt.%, lignite as coal) and 40 mL of water-methanol mixture were added to the reaction kettle. The volume percentage of methanol in the water-alcohol mixture medium is 60%, the liquefaction temperature is 360°C, the pressure is 39.00MPa, and the reaction time is 90min. The liquefaction rate of the obtained coal and algae is 70.82%, and the oil production rate is 38.19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com