Automobile tire recovery processing method

An automobile tire and recycling technology, applied in the field of rubber recycling, can solve the problems of heavy pollution, high energy consumption, restricting the development of the enterprise industry, etc., and achieve the effect of high oil quality and oil yield, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

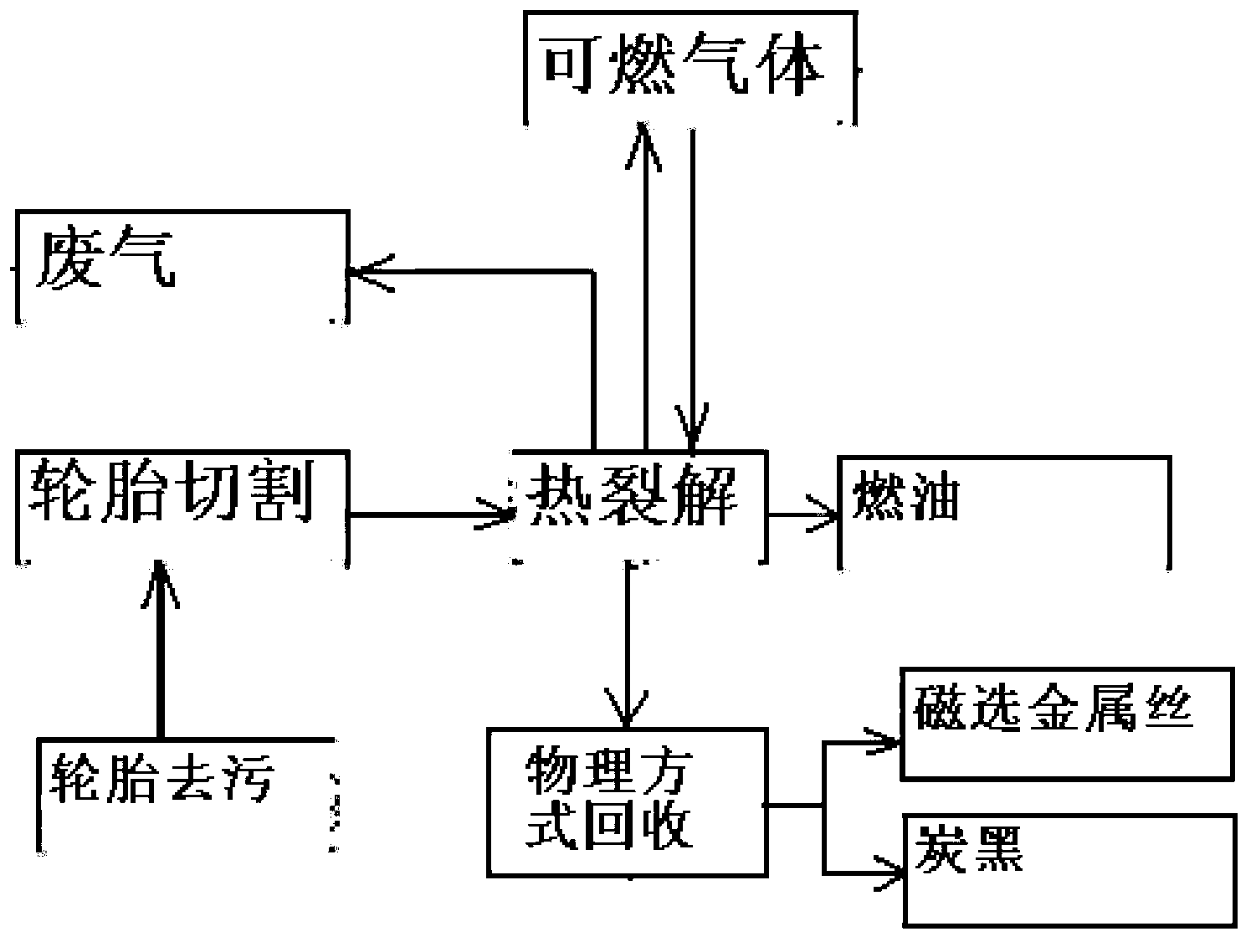

[0011] This embodiment provides a method for recycling automobile tires, which is characterized in that: the method for recycling automobile tires mainly includes decontaminating the automobile tires and breaking them into strips with an end surface area of less than 50 square millimeters. Rubber is thermally cracked in a special thermal cracking furnace at a temperature of 450°C and under a negative pressure of 0.05 MPa for 10 minutes. The gas and oil are recovered and separated through a condenser. The primary fuel used for cracking is coal After continuous operation of the cracking device, all the combustible gas produced can be returned to the bottom of the furnace as a secondary energy source for pyrolysis heating, replacing 30% of the primary energy. Electromagnets are used to remove the metal part, and the carbon black is 700 mesh.

[0012] The structure of the special pyrolysis furnace is a split barrel structure, the sealing and opening are controlled by electromagne...

Embodiment 2

[0014] This embodiment provides a method for recycling automobile tires, which is characterized in that: the method for recycling automobile tires mainly includes decontaminating the automobile tires and breaking them into strips with an end surface area of less than 50 square millimeters. Rubber is thermally cracked in a special thermal cracking furnace at a temperature of 475°C and under a negative pressure of 0.06 MPa for 13 minutes. The gas and oil are recovered and separated through a condenser. The primary fuel used for cracking is coal After continuous operation of the cracking device, all the combustible gas produced can be returned to the bottom of the furnace as a secondary energy source for cracking heating, replacing 35% of the primary energy. Electromagnets are used to remove metal parts, and the carbon black is 800 mesh.

[0015] The structure of the special pyrolysis furnace is a split barrel structure, the sealing and opening are controlled by electromagnet po...

Embodiment 3

[0017] This embodiment provides a method for recycling automobile tires, which is characterized in that: the method for recycling automobile tires mainly includes decontaminating the automobile tires and breaking them into strips with an end surface area of less than 50 square millimeters. Rubber is thermally cracked in a special thermal cracking furnace at a temperature of 500°C and under a negative pressure of 0.07 MPa for 15 minutes. The gas and oil are recovered and separated through a condenser. The primary fuel used for cracking is coal After continuous operation of the cracking device, all the combustible gas produced can be returned to the bottom of the furnace as a secondary energy source for cracking heating, replacing 40% of the primary energy. Electromagnets are used to remove metal parts, and the carbon black is 900 mesh.

[0018] The structure of the special pyrolysis furnace is a split barrel structure, the sealing and opening are controlled by electromagnet po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com