Preparation method of anti-corrosion high-temperature-resistant wear-resistant casting pipe

A high-temperature-resistant and wear-resistant pipeline technology, applied in anti-corrosion coatings, manufacturing tools, heat treatment equipment, etc., can solve problems such as inappropriateness, and achieve the effects of improving work efficiency, low production costs, and strong resistance to organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

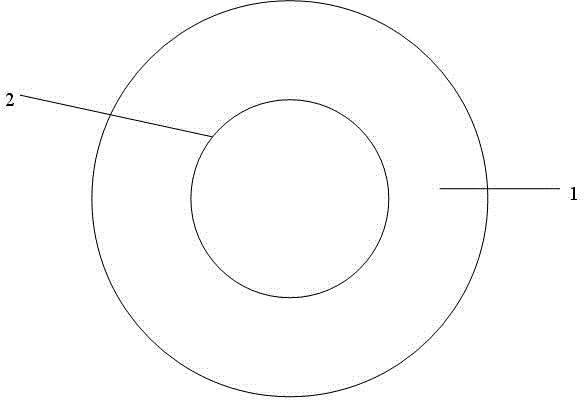

Image

Examples

Embodiment 1

[0057] A) Preparation of wear-resistant pipe body

[0058] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0059] C: 1.6%, V: 4.5%,

[0060] W: 9.1%, Mo: 7.6%,

[0061] Cr: 3.8%, RE: 0.15%,

[0062] Mn: 0.7%, Si: 0.05%,

[0063] B: 0.02%, Al: 0.2%,

[0064] Nb: 0.08%, Ni: 0.1%,

[0065] The balance is Fe and trace unavoidable impurities;

[0066] 2) Mix and heat ordinary steel scrap, micro-carbon ferrochrome, ferroniobium, ferronickel, ferrotungsten, ferromolybdenum, ferrochrome and ferromanganese, add carbon with pig iron or graphite, mix and heat to melt into molten steel, and add the molten steel after it is melted Ferrosilicon for pre-deoxidation;

[0067] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1580°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0068] 4) Put the rare earth ferrosi...

Embodiment 2

[0090] A) Preparation of wear-resistant pipe body

[0091] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0092] C: 2.7%, V: 6.0%,

[0093] W: 6.9%, Mo: 5.3%,

[0094] Cr: 5.4%, RE: 0.23%,

[0095] Mn: 0.6%, Si: 0.08%,

[0096] B: 0.01%, Al: 0.5%,

[0097] Nb: 1.1%, Ni: 0.2%,

[0098] The balance is Fe and trace unavoidable impurities;

[0099] 2) Mix and heat ordinary steel scrap, micro-carbon ferrochrome, ferroniobium, ferronickel, ferrotungsten, ferromolybdenum, ferrochrome and ferromanganese, add carbon with pig iron or graphite, mix and heat to melt into molten steel, and add the molten steel after it is melted Ferrosilicon for pre-deoxidation;

[0100] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1600°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0101] 4) Put the rare earth ferrosil...

Embodiment 3

[0123] A) Preparation of wear-resistant pipe body

[0124] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0125] C: 3.7%, V: 8.5%,

[0126] W: 3.2%, Mo: 2.4%,

[0127] Cr: 8.9%, RE: 0.4%,

[0128] Mn: 0.3%, Si: 1.0%,

[0129] B: 0.01%, Al: 0.8%,

[0130] Nb: 2.4%, Ni: 0.3%,

[0131] The balance is Fe and trace unavoidable impurities;

[0132] 2) Mix and heat ordinary steel scrap, micro-carbon ferrochromium, ferroniobium, ferronickel, ferrotungsten, ferromolybdenum, ferrochromium, ferroniobium, ferronickel and ferromanganese, add carbon with pig iron or graphite, mix and heat and melt into molten steel After the molten steel is melted, ferrosilicon is added for pre-deoxidation;

[0133] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1630°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0134] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com