Non-superimposition beam type fabricated frame-shear wall connection structure and construction method thereof

A technology for connecting structures and shear walls, which is applied to walls, building components, building structures, etc., can solve the problems of large number of steel sleeves, time-consuming, high manufacturing precision requirements, etc., to improve overall performance, convenient construction, and earthquake resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

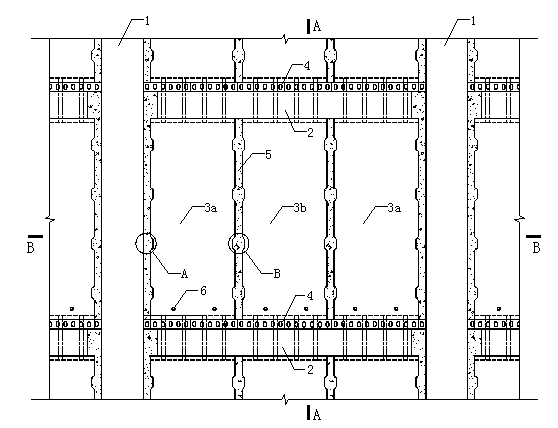

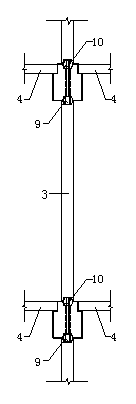

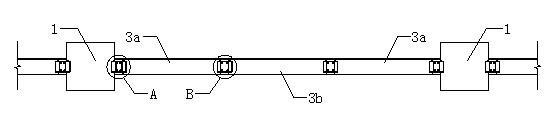

[0037] Embodiment: The non-superposed beam type assembled frame-shear wall connection structure of this embodiment is as follows figure 1 , figure 2 and image 3 As shown, it includes a column 1 prefabricated by concrete, an ear beam 2 and a shear wall 3, the column 1 and the shear wall 3 are connected in sequence in the horizontal direction, and the top of the shear wall 3 is installed with an ear beam 2, Floor slabs 4 are overlapped on the ear beams 2, and post-cast concrete 5 is filled on the connection interfaces of the above-mentioned components.

[0038] Such as Figure 4~6As shown, anchor ring steel bars 8 are pre-embedded on the side wall of the column 1 at the junction of the column 1 and the shear wall 3 . The left and right sides of the shear wall are also equipped with anchor ring steel bars 8. When the shear wall is installed, after the anchor ring steel bars on both sides of the wall are overlapped up and down, vertically insert the vertical connection longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com