Sample preparation method of alloying hot-dip galvanized coating section transmission sample

A hot-dip galvanizing and alloying technology, applied in the field of transmission electron microscope analysis of alloy coatings, can solve the problems of high cost, demanding sample preparation conditions, and inability to effectively prevent the outer layer from loosening and falling off, so as to achieve the effect of preventing falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of DX56D+Z alloyed hot-dip galvanized layer section transmission electron microscope sample

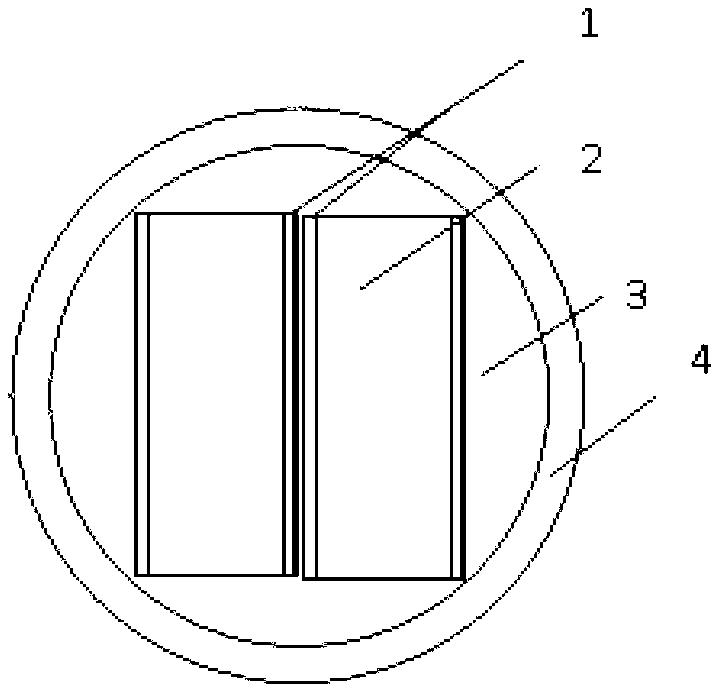

[0017] (1) Pre-cut sample: The thickness of the sample plate is 0.6 mm, and the inner diameter of the copper tube is 2.4 mm. According to the geometric relationship between the sample and the copper tube, the width of the sample is calculated to be 2.0 mm. The sample was cut into 2 strips of 2.0mm wide and 15mm long.

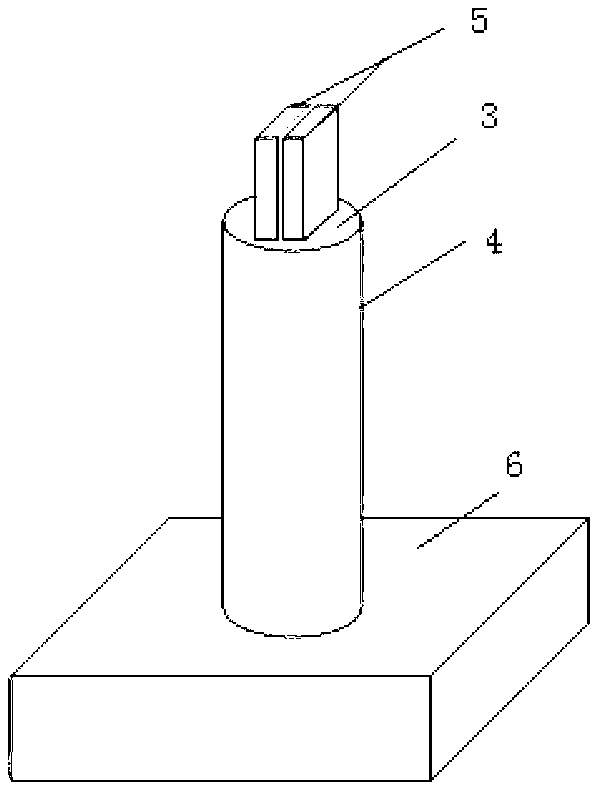

[0018] (2) Fix the sample: After gluing the two cut strip samples with G1 glue, let them stand on a hot stage at 130°C for 15 minutes until the glue is completely cured. Then put the copper tube into it and fix it with G1 glue, place it upright in the pit of the sample stage, and place it on a hot stage at 130°C for 15 minutes after the air bubbles are completely discharged.

[0019] (3) Slicing: Use a high-precision diamond grinding wheel to cut the copper tube vertically to obtain a disc with a thickness of 0.2mm and a diameter of 3.05mm.

[0020]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com