Zero addictive environment-friendly composite shell and manufacturing process thereof

A technology of composite fabric and manufacturing process, applied in the field of textile fabrics, to achieve the effect of soft texture, low cost, excellent elasticity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

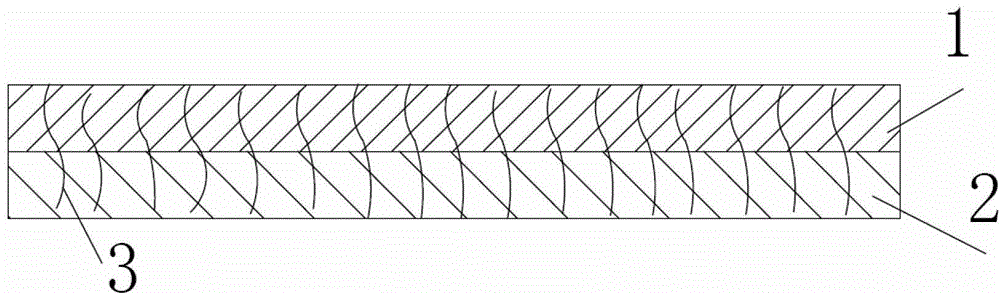

[0026] The present invention is a zero-additive environment-friendly composite fabric, such as figure 1 As shown, the composite fabric includes a base layer fabric 2 and a woolen woven fabric 1, the woolen woven fabric 1 and the base layer fabric 2 are compounded by needle punching, and the wool fiber 3 in the woolen woven fabric 1 passes through Acupuncture passes through the base fabric 2, and the woolen woven fabric 1 is combined with the base fabric 2; wherein the wool fiber can be one of wool fiber, rabbit hair fiber and camel hair fiber or any combination thereof, Preferably the wool fiber is wool fiber, and the woolen woven fabric 1 is the woolen woven fabric.

[0027] In addition, the woolen woven fabric 1 is a woolen plain fabric with a warp density of 10.5-12.5 threads / cm and a weft density of 10-12 threads / cm. The yarn counts of the warp and weft threads are 10-12. Cotton woven fabrics, of course the base fabric 2 can also be other woven fabrics such as wool and ch...

Embodiment 2

[0032] The present invention is a zero-additive environment-friendly composite fabric, such as figure 1 As shown, the composite fabric includes a base layer fabric 2 and a woolen woven fabric 1, the woolen woven fabric 1 and the base layer fabric 2 are compounded by needle punching, and the wool fiber 3 in the woolen woven fabric 1 passes through Acupuncture passes through the base fabric 2, and the woolen woven fabric 1 is combined with the base fabric 2; wherein the wool fiber can be one of wool fiber, rabbit hair fiber and camel hair fiber or any combination thereof, Preferably the wool fiber is wool fiber, and the woolen woven fabric 1 is the woolen woven fabric.

[0033] Among them, the woolen woven fabric 1 is a woolen twill fabric with a warp density of 13-16 threads / cm and a weft density of 12.5-15.5 threads / cm, and the warp and weft yarn counts are 10-12; the base fabric 2 is knitted The cloth fabric can be specifically one of wool knitted fabric, chemical fiber knit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com