Process for producing albite

A production method, the technology of albite, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of complex process, product loss, high production cost, etc., achieve the effect of simple production process, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The production equipment used in this embodiment is commonly used mining machinery, which is a known technology. In this embodiment, the Xianyang ceramic plunger pump of model Y200-20, Xingyuan van filter press and piston air compressor of model X25MDYW800-UB are selected for dehydration in the process of filter press shrinkage; 2 The deep conical inclined tube thickener thickens the slurry, and can also be used for other commonly used mining machinery and equipment.

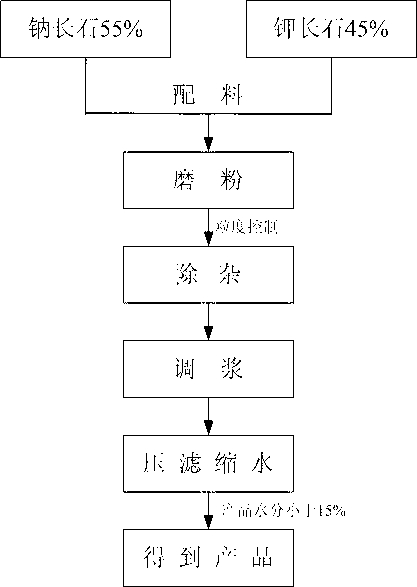

[0037] A kind of production method of albite, its step is as follows:

[0038] (1), ingredients

[0039] Select Hunan Hengyang hydrophilic albite feldspar and Guangdong Qingyuan hydrophobic potassium feldspar and crush them into granular raw materials with a particle size of less than 5mm, and then make 55% of Hunan Hengyang hydrophilic albite and Guangdong Qingyuan hydrophobic potassium feldspar according to the weight percentage of raw materials. 45% of feldspar is batched, and the main chemical compo...

Embodiment 2

[0050] The production equipment used in this embodiment is commonly used mining machinery, which is a known technology. In this embodiment, the Xianyang ceramic plunger pump of model Y200-20, Xingyuan van filter press and piston air compressor of model X25MDYW800-UB are selected for dehydration in the process of filter press shrinkage; 2 The deep conical inclined tube thickener thickens the slurry, and can also be used for other commonly used mining machinery and equipment.

[0051] A kind of production method of albite, its step is as follows:

[0052] (1), ingredients

[0053] Select Hunan Hengyang hydrophilic albite feldspar and Guangdong Qingyuan hydrophobic potassium feldspar and crush them into granular raw materials with a particle size of less than 5mm, and then make 55% of Hunan Hengyang hydrophilic albite and Guangdong Qingyuan hydrophobic potassium feldspar according to the weight percentage of raw materials. 45% of feldspar is batched, and the main chemical compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com