One-component ultraviolet-light-anaerobic dual-curing adhesive

A dual-curing, ultraviolet light technology, applied in the direction of adhesives, modified epoxy resin adhesives, adhesive types, etc., can solve the problems of low shear strength, unsuitable for shading or translucent materials, etc., to achieve bonding High reliability, wide application range and excellent curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

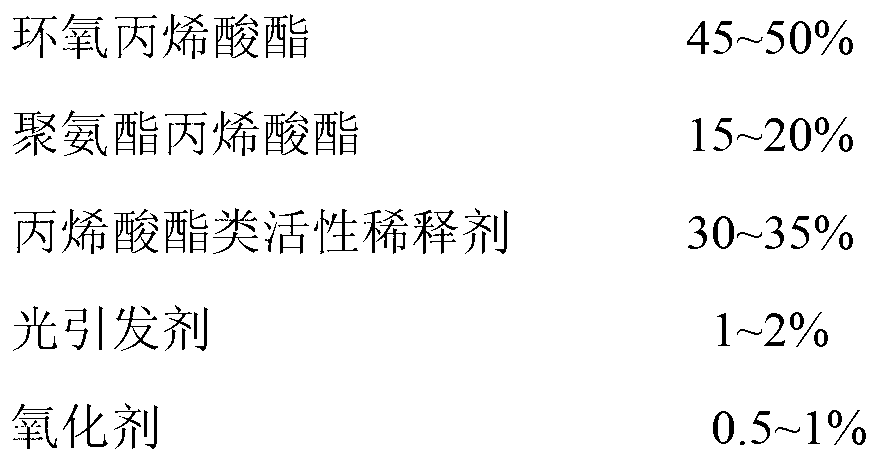

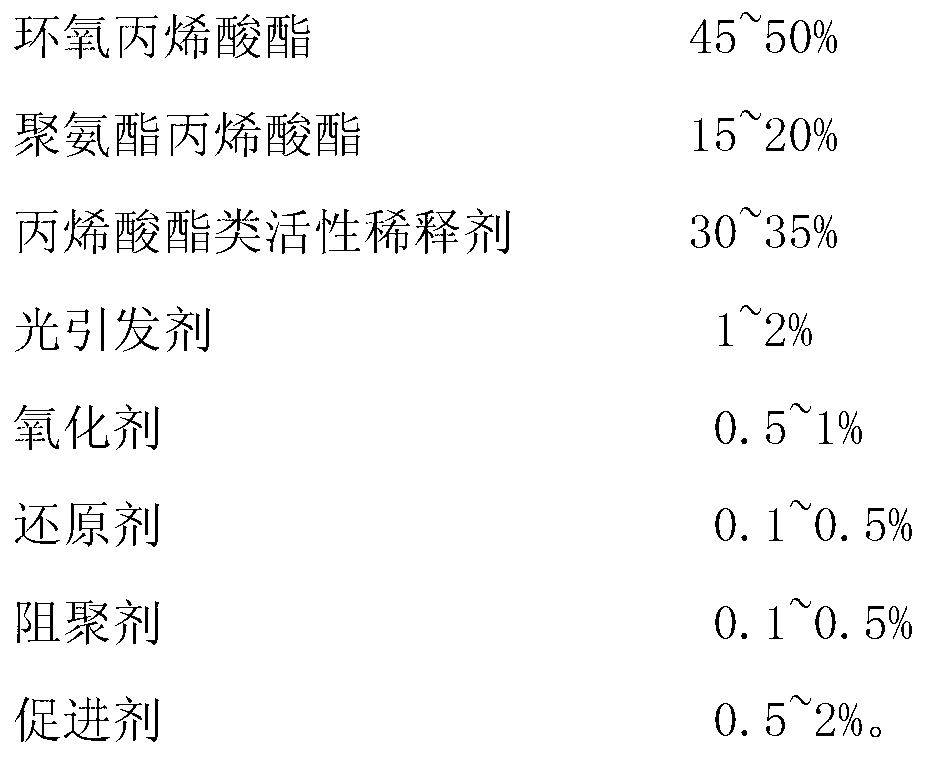

[0027] 1. The composition and ratio of UV-anaerobic dual curing adhesive. The ultraviolet light-anaerobic dual curing adhesive of the embodiment 1-18 of the present invention is made of the following raw materials in weight percentage:

[0028]

[0029] (The symbol " / " in the table means none)

[0030] 2. Performance test. The sample of embodiment 1-18 and existing common photocurable adhesive have been carried out the comparative test of mechanical property by following method:

[0031] Sample preparation method: apply glue to two stainless steel plates for curing;

[0032] Light curing conditions: light intensity 80W / cm 2 , light time 15s;

[0033] Post-curing conditions: 48 hours at room temperature or 1.5 hours at 80 degrees;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com