Hollow interlayer heat-insulating wall board and processing and manufacturing method thereof

A thermal insulation wallboard and hollow technology, applied in the direction of thermal insulation, building components, etc., can solve the problems that aluminum foil is not easy to support and tighten, difficult to assemble and process, easy to tear, etc., to meet the cost performance requirements, solve the difficulty of assembly and processing, eliminate The effect of making errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Hollow interlayer thermal insulation wallboard.

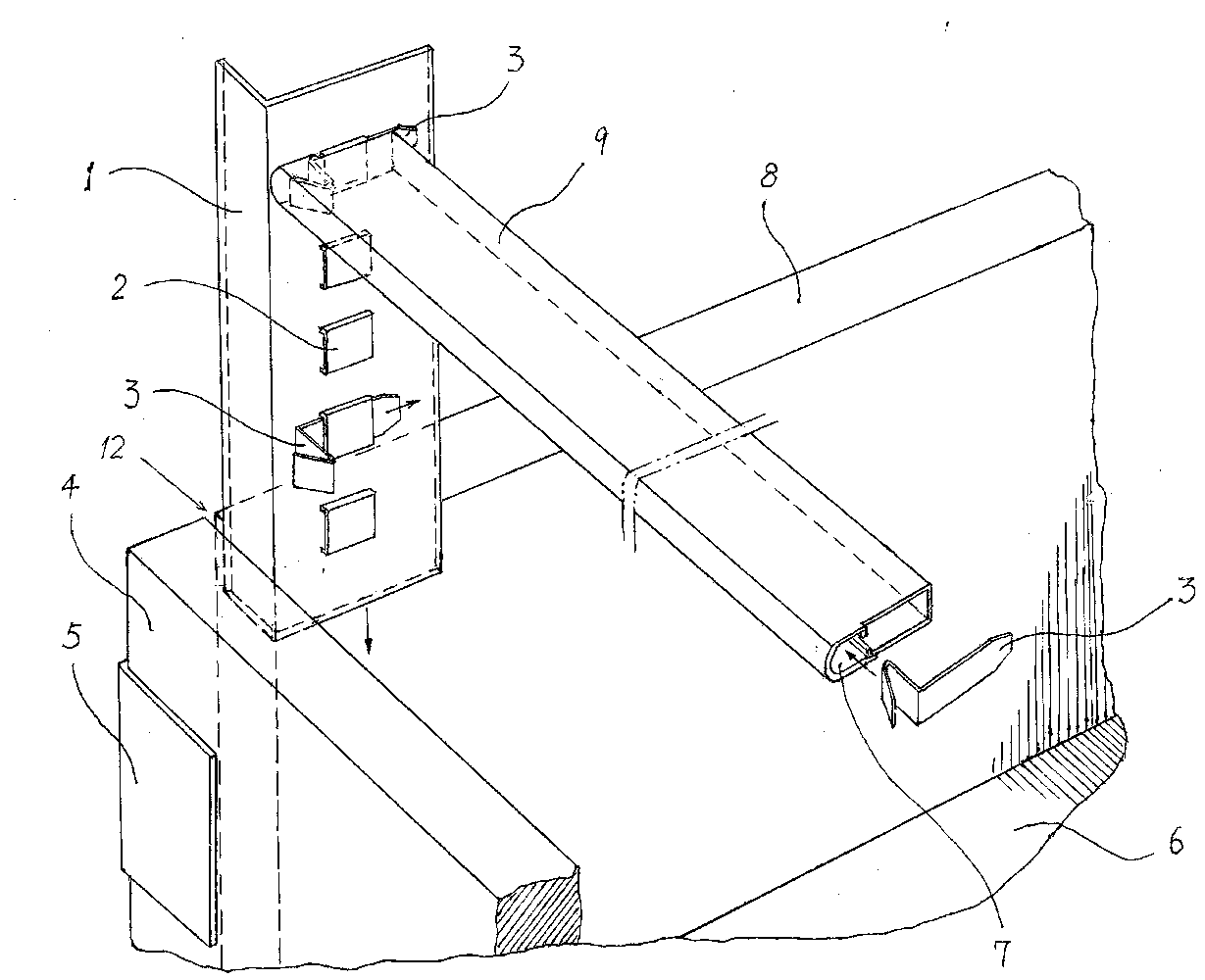

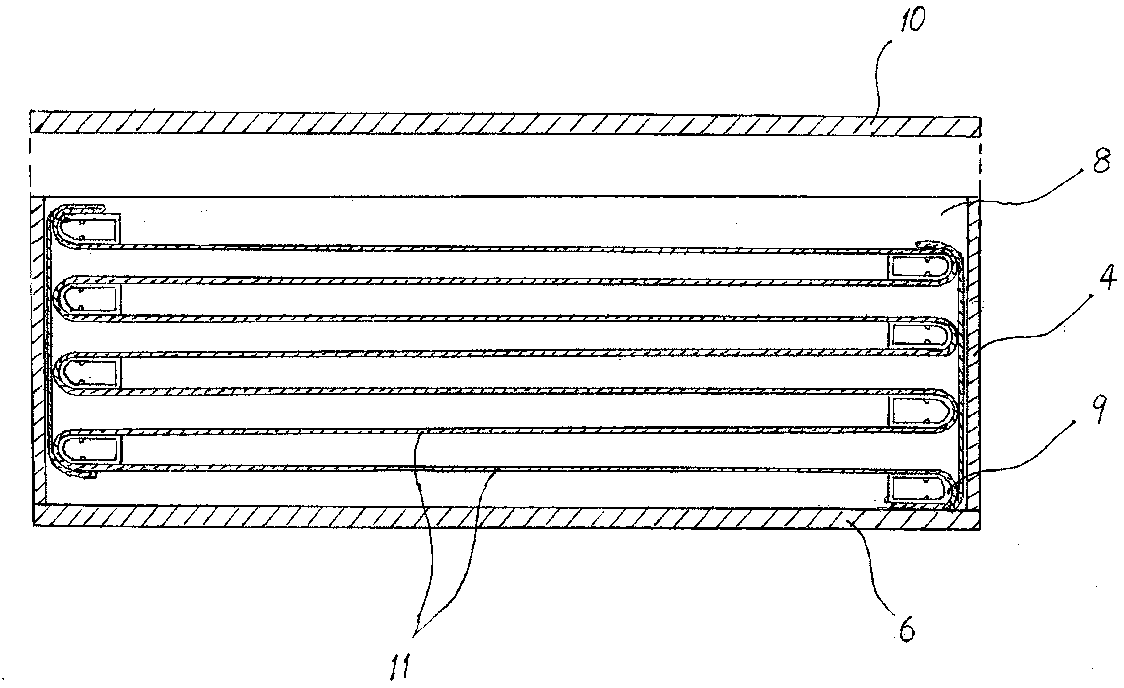

[0030] Such as figure 1 , figure 2 As shown, the hollow interlayer thermal insulation wallboard of the present invention includes two components of a shell and a diaphragm winding.

[0031] The shell is in the shape of a cuboid, surrounded by two side plates 8, two end plates 4, a bottom plate 6 and a top plate 10. A clamping gap 12 of about 1mm is left, and the clamping gap can be formed by fixing the end plate and the side plate by the outer fixing plate 5, or can be formed by processing the stepped surface of the end surface of the side plate. The top plate 10 on the casing is sealed and positioned after the diaphragm winding is assembled.

[0032] Diaphragm windings are continuously wound on the support with diaphragm 11 to form several air compartments. The diaphragm 11 used is a film material with low emissivity and high reflectivity. Aluminum foil can be selected, or a composite layer with alumi...

Embodiment 2

[0039] Embodiment 2: The processing and manufacturing method of the insulating wallboard with hollow interlayer.

[0040] refer to figure 1 , figure 2 , the processing and manufacturing method of the hollow interlayer insulation wallboard of the present invention comprises the following steps:

[0041] a, the making of the housing: on the assembly platform, assemble two side plates 8, two end plates 4 and a base plate 6 into a cuboid housing with an open top, and cover the top plate 10 for the open top The size is the same as that of the bottom plate 6, and it is placed for use; when assembling the shell, a 0.9-1.5mm clamping gap 12 ( figure 1 ).

[0042] b. Production of card holder: punch a long strip of metal sheet along the long direction into an L-shaped folded corner card holder 1 ( figure 1 ), on one of the folded edges of the deck 1, a number of horizontal slots 2 equidistantly distributed and with horizontal penetration openings are stamped out longitudinally, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com