Cutting torch and manufacturing method thereof

A manufacturing method and cutting nozzle technology, applied in the direction of combustion method, gas fuel burner, combustion type, etc., can solve the problems of inability to clean slag, difficult disassembly and disassembly of cutting nozzles, etc., to improve strength and heat resistance Sexuality and other properties, unobstructed air outlet, and easy coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

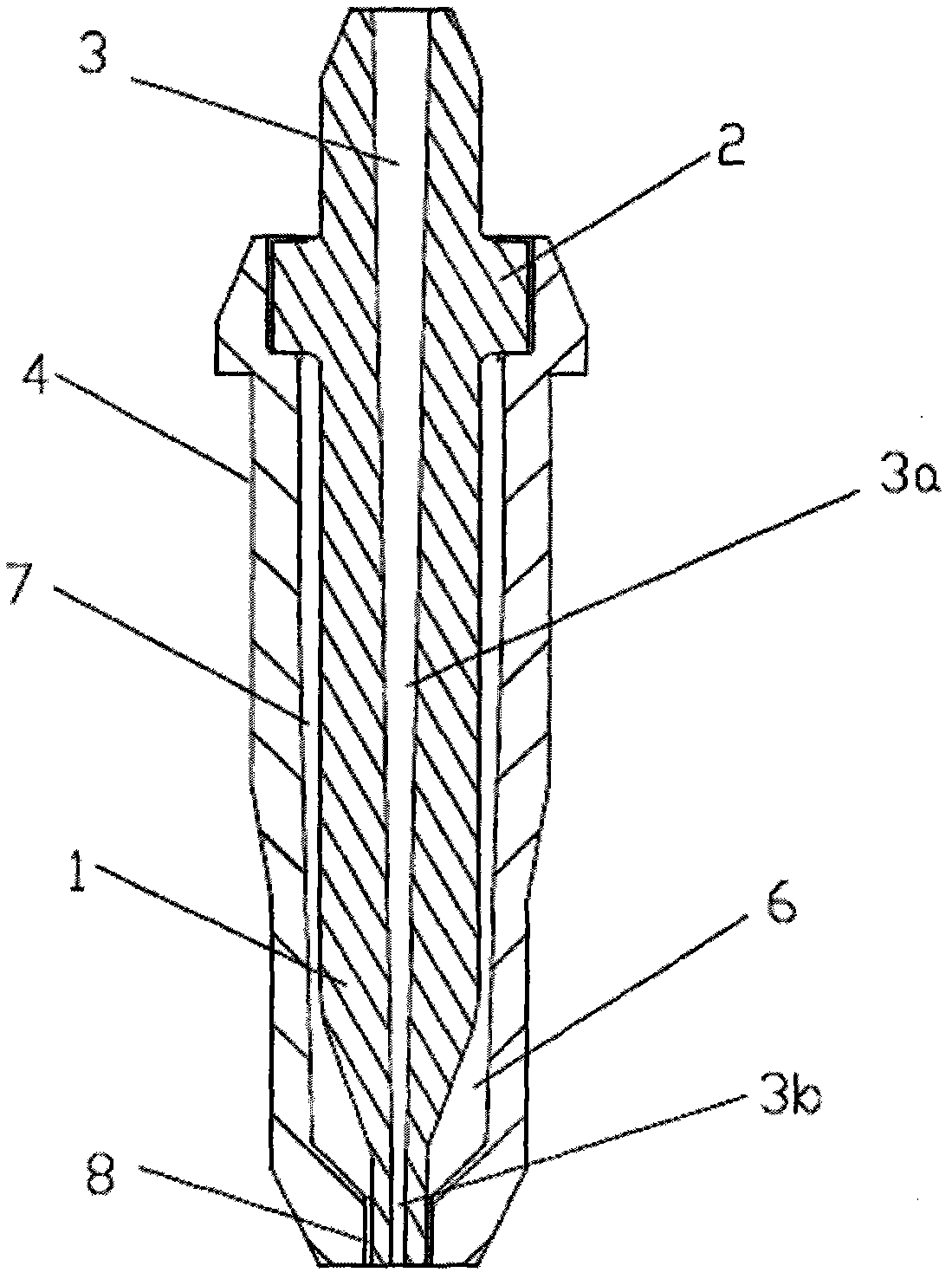

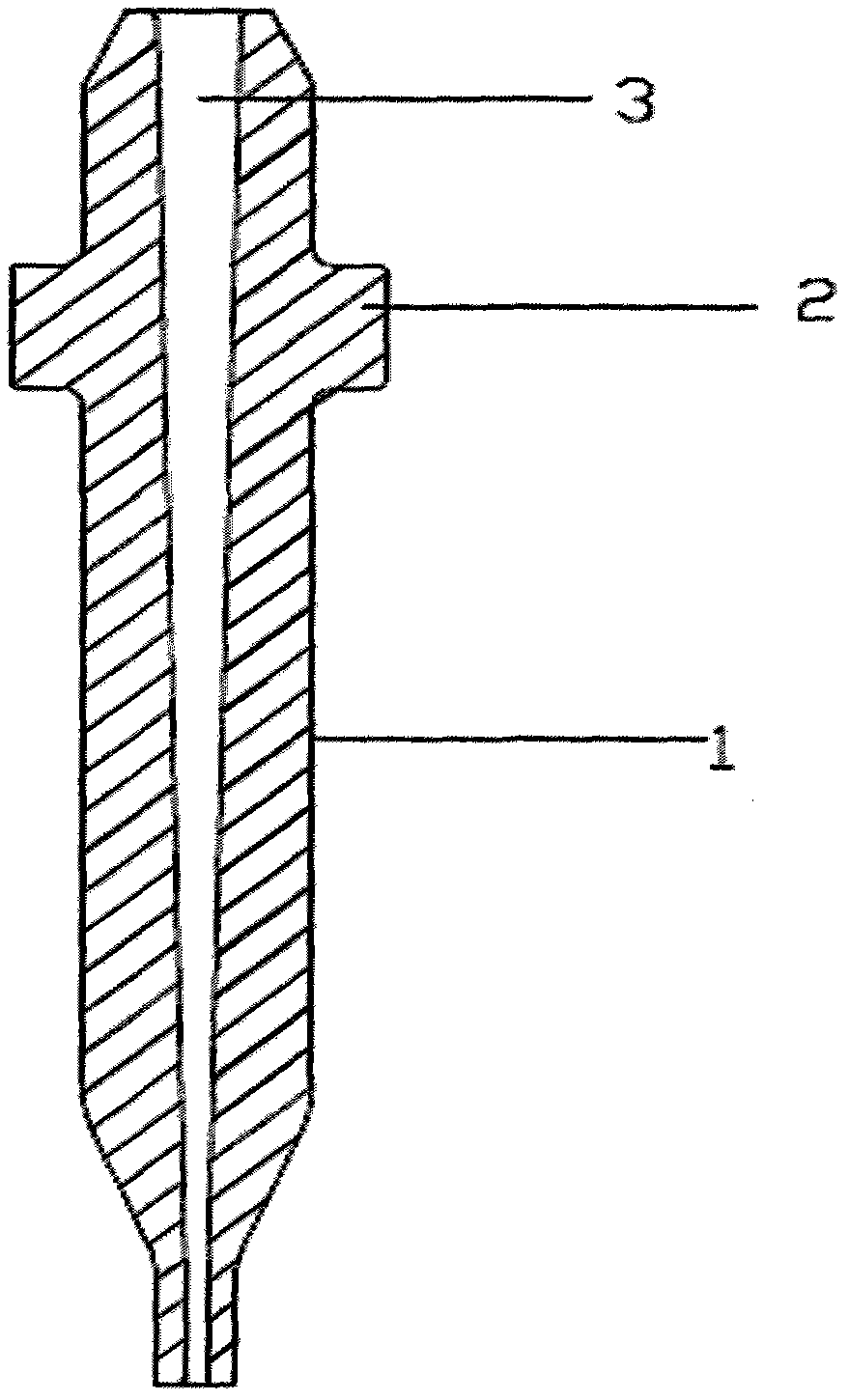

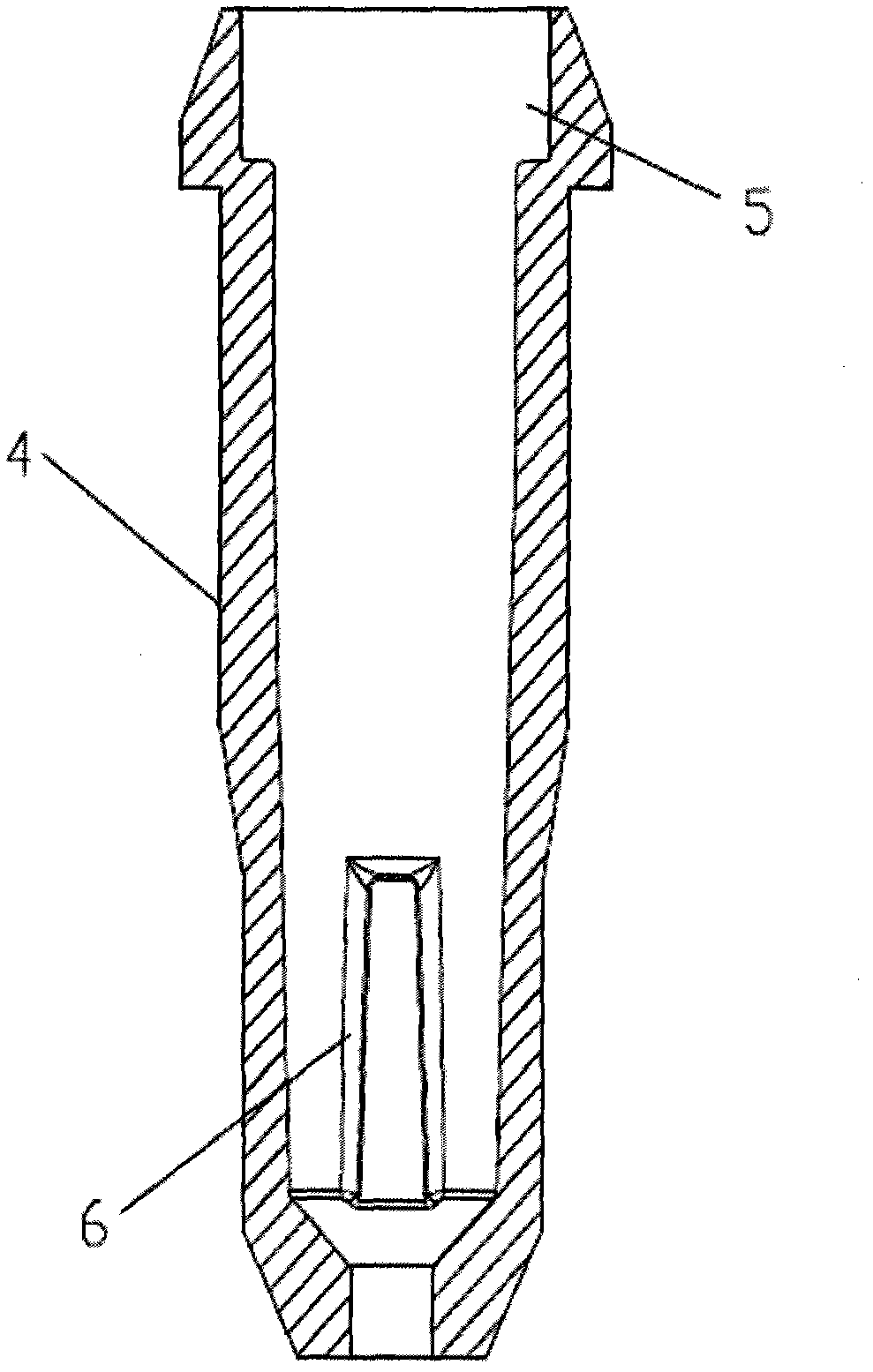

[0029] Example 1 as figure 1 As shown, a cutting nozzle is composed of a central tube 1 and a shell 4; the outer wall of the central tube 1 is provided with a wing platform 2; the inner wall of the shell 4 is provided with a sinker 5 and a rib platform 6; , where the wing platform 2 of the center tube matches the sinking groove 5 on the inner wall of the shell, and axially positions the center tube 1 and the shell 4, and the rib platform 6 on the inner wall of the shell contacts and cooperates with the outer wall of the core tube of the center tube 1, and aligns the center The tube 1 and the shell 4 are radially positioned to ensure the concentricity of the central tube 1 and the shell 4; the central tube 1 is provided with an oxygen channel 3, and the oxygen channel is divided into two sections: a conical section 3a and a cylindrical section 3b; the central tube 1 A gas channel 7 is formed between the outer wall and the inner wall of the shell 4, and the gas channel 7 forms a...

Embodiment 2

[0032] Embodiment 2 A manufacturing method of a cutting nozzle. In this embodiment, the production cutting nozzle is made of 17-4PH stainless steel material, and the central tube 1 and the shell 4 of the cutting nozzle are processed and manufactured by using the powder metallurgy process. The specific steps are as follows:

[0033] (1) Select 17-4PH stainless steel metal powder that meets the specification requirements. The stainless steel powder is produced by water atomization or gas atomization process, with a particle size range of 2-20 μm and a tap density of 45%.

[0034] (2) Select the molding binder suitable for 17-4PH stainless steel powder, carry out mixing and granulation with the stainless steel powder and binder using a high-speed mixer and an extruder, and make feed suitable for injection molding; Percentage by weight, 17-4PH stainless steel powder accounts for 85% of the feed, and the binder accounts for 15% of the feed; the binder is polypropylene, polystyrene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com