Air-gas linkage ratio adjustment and control system of combustor in commercial kitchen equipment

A proportional adjustment and air-gas linkage technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems such as failure to achieve simultaneous deployment of air and air, incomplete combustion of gas, waste of resources, etc., to eliminate gas energy Waste, simple and reasonable structure, convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

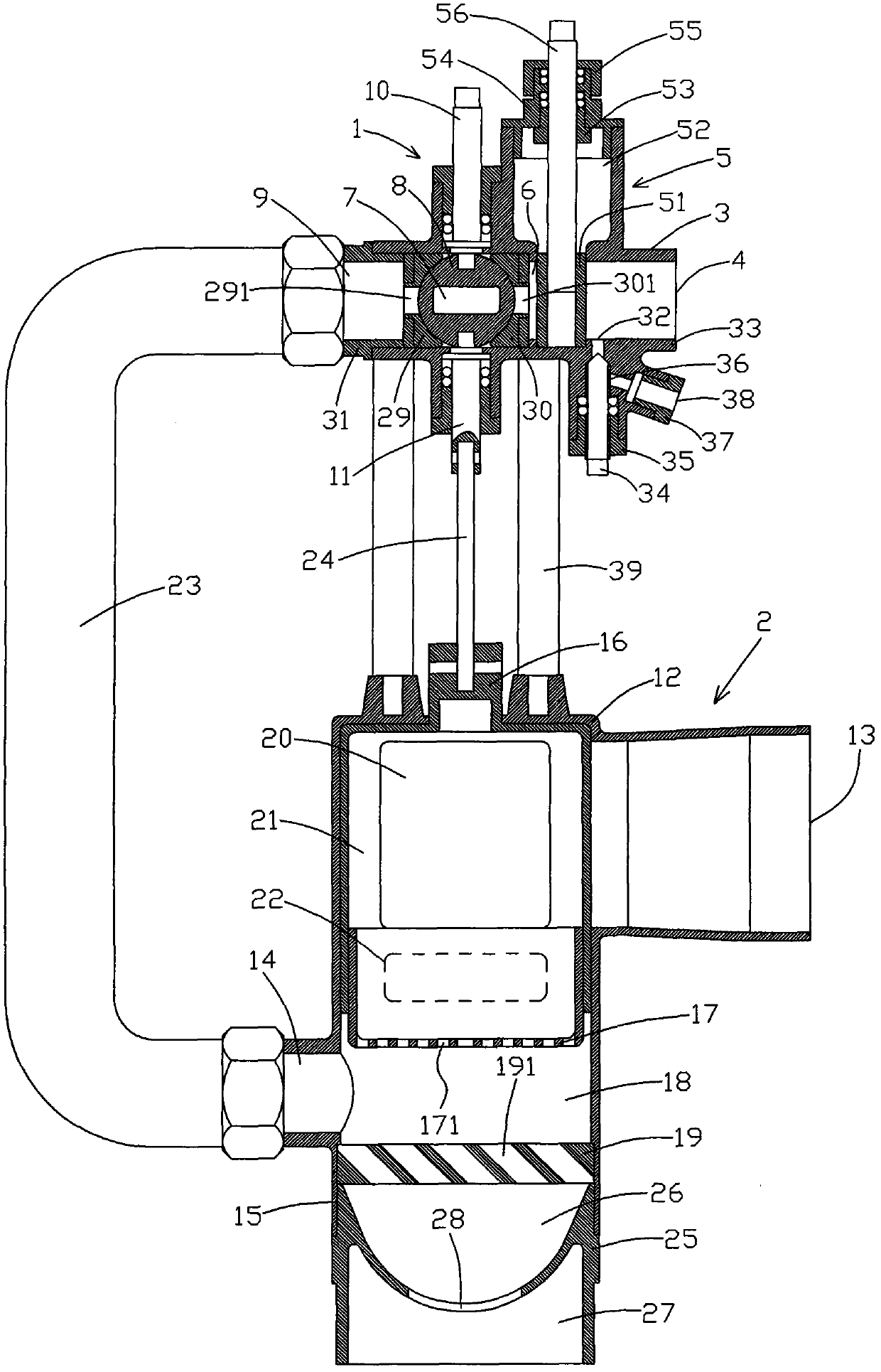

[0022] Such as figure 1 As shown, an air-air linkage proportional adjustment control system for a burner according to an embodiment of the present invention includes a gas proportional adjustment control valve 1 and an air proportional adjustment control valve 2 .

[0023] The gas proportional adjustment control valve 1 includes: a one-time forged three-way structure air cavity base 3, and a gas main air inlet 4, a seedling fire needle valve gas inlet 32, and a main Fire gas flow control mechanism 5, main fire gas inlet 6, main fire ball valve right sealing ring 30, main fire ball valve with square gas inlet 7 8, main fire ball valve left sealing ring 29, main fire ball valve positioning pipe 31 and main fire gas exit 9. The left and right sealing rings 29 and 30 of the main fire ball valve are provided with vent holes 291 and 301 for the main fire gas to flow through. The control handle 11 and the upper end of the main fire ball valve control rod 10 are provided with a fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com