Wind turbine coupling slip torque calibration test bench and calibration method

A technology of couplings and flanges, which is applied to the slipping torque calibration test bench of wind turbine couplings and the field of calibration, can solve problems such as large slipping torque calibration errors, lagging test judgments, complex mechanisms, etc., and achieve good application value , Easy to adjust, good human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

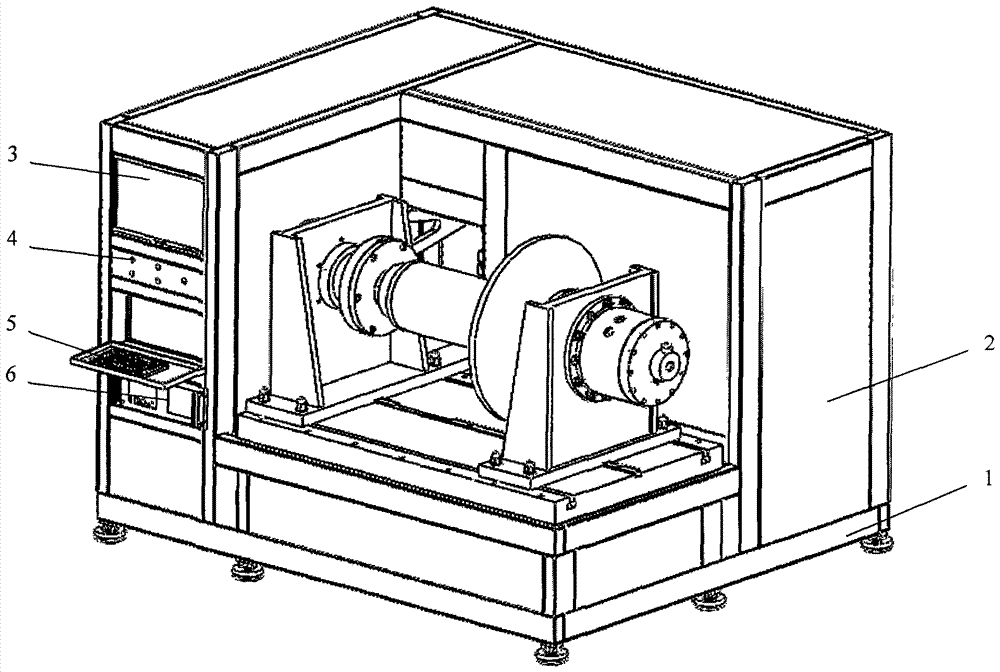

[0023] The wind power generator coupling slip torque calibration test bench of the present invention is mainly composed of a bench, a bottom plate, a torque loading mechanism, a torque output detection mechanism, a hydraulic system, and a computer control system; the bottom plate, the torque loading mechanism, a torque output detection mechanism, a hydraulic The system and computer control system are all installed and fixed on the stand.

[0024] see figure 1 , The bench adopts section steel welded frame 1, and the surface is equipped with steel plate door 2. For the anti-rust and beautiful appearance of the test bench, the surface of the test bench is spray-painted.

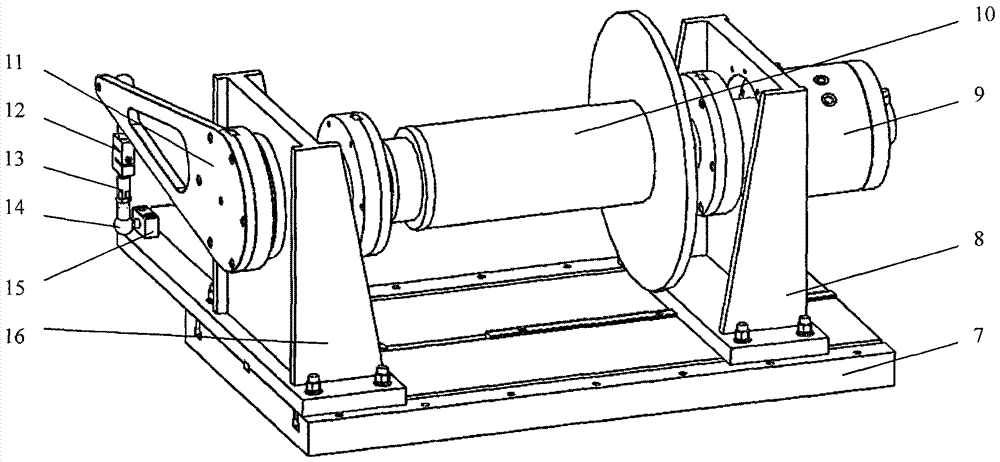

[0025] see figure 2 , the bottom plate 7 is a thick steel plate, fixed on the stand; there is a longitudinally penetrating flat keyway in the middle of the upper surface of the bottom plate, the flat key is put into the flat keyway and fixed with bolts, and there is a longitudinally penetrating T-shaped groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com