Method for manufacturing cathode of total-tantalum electrolytic capacitor

A tantalum electrolytic capacitor and cathode technology, applied in the field of electronic materials, can solve the problems of difficulty in electroplating platinum black, difficulty in increasing the capacity of capacitors, and small cathode area, and achieve the effects of increasing cathode area, increasing capacity, and increasing effective area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

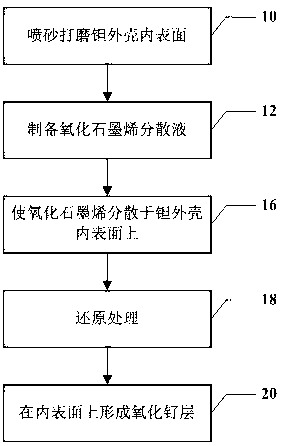

[0059] (1) Use 400-mesh steel grit to blast the inner surface of the tantalum shell of Φ10×100mm under the pressure of 0.6Mpa for 1min;

[0060] (2) The tantalum case after sandblasting was ultrasonically cleaned with acetone and deionized water for 1 hour, and dried at 100°C for later use;

[0061] (3) Add 2 ml of graphene oxide dispersion at a concentration of 2 mg / ml to the cleaned tantalum case;

[0062] (4) Rotate the tantalum shell containing the graphene oxide dispersion for 30s at a rate of 50 rpm;

[0063] (5) Place the tantalum shell in a vacuum of 1.1×10 -4 pa, the temperature is 200°C for 1 hour, and graphene oxide is reduced to graphene at this time;

[0064] (6) Repeat (4)~(5) process 3 times;

[0065] (7) Use the entire tantalum shell as the electrochemical reaction tank and working electrode, add 7ml of electrolyte, insert platinum wire and silver / silver chloride electrode respectively, and the cycle voltage is -0.2~1V, and the scanning speed is 200mV / s. Th...

example 2

[0070] (1) Use 400 mesh steel grit on the inner surface of the tantalum shell of Φ20×120mm, and blast it for 2 minutes under the pressure of 0.6Mpa;

[0071] (2) The tantalum case after sandblasting was ultrasonically cleaned with acetone and deionized water for 1 hour, and dried at 100°C for later use;

[0072] (3) Add 9 ml of graphene oxide dispersion at a concentration of 2 mg / ml to the cleaned tantalum case;

[0073] (4) Rotate the tantalum shell containing the graphene oxide dispersion for 30s at a rate of 50 rpm;

[0074] (5) Put the tantalum shell in a vacuum of 9.7×10 -5 pa, the temperature is 200°C for 1 hour, and graphene oxide is reduced to graphene at this time;

[0075] (6) Repeat (4)~(5) process 3 times;

[0076] (7) Use the entire tantalum shell as the electrochemical reaction tank and working electrode, add 32ml of electrolyte, insert platinum wire and silver / silver chloride electrode respectively, and the cycle voltage is -0.2~1V, and the scanning speed i...

example 3

[0081] (1) Use 400-mesh steel grit to blast the inner surface of the tantalum shell of Φ10×100mm under the pressure of 0.6Mpa for 1min;

[0082] (2) The tantalum case after sandblasting was ultrasonically cleaned with acetone and deionized water for 1 hour, and dried at 100°C for later use;

[0083] (3) Add 2 ml of graphene oxide dispersion at a concentration of 5 mg / ml to the cleaned tantalum case;

[0084] (4) Rotate the tantalum shell containing the graphene oxide dispersion for 30s at a rate of 50 rpm;

[0085] (5) Put the tantalum shell in a vacuum of 8.7×10 -5 pa, the temperature is 200°C for 1.5 hours, at which time graphene oxide is reduced to graphene;

[0086] (6) Repeat (4)~(5) process 3 times;

[0087] (7) Use the entire tantalum shell as the electrochemical reaction tank and working electrode, add 7ml of electrolyte, insert platinum wire and silver / silver chloride electrode respectively, and the cycle voltage is -0.2~1V, and the scanning speed is 200mV / s. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com