Method for improving quality of diamond wire coating

A diamond wire and quality technology, applied in the field of improving the quality of the diamond wire coating, can solve the problems of uneven thickness of the electroplated corundum coating, reduced corundum yield, serious cathode agglomeration, etc. The effect of cathodic adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

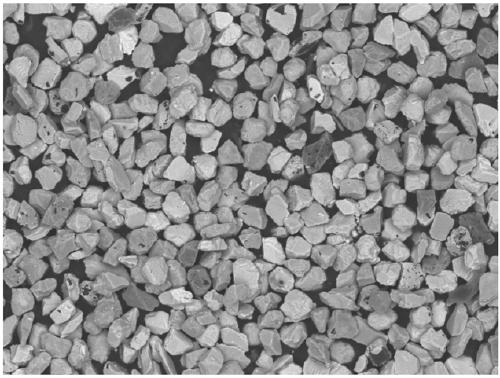

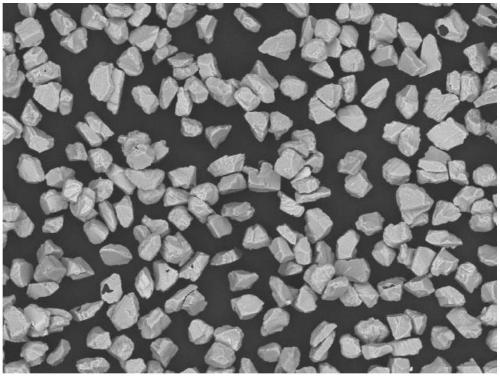

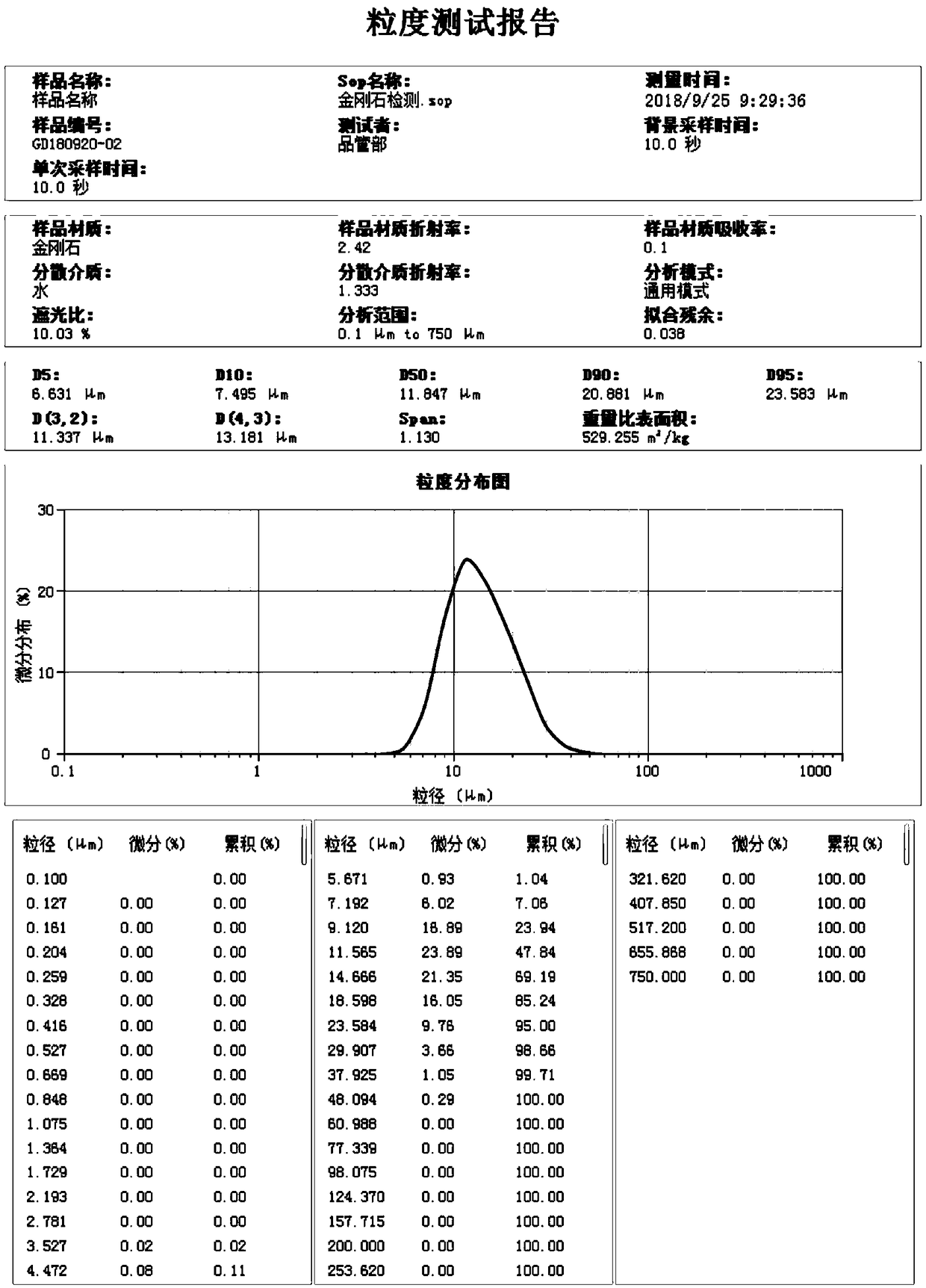

Image

Examples

Embodiment 1

[0025] The method for improving the coating quality of diamond wire includes the following steps:

[0026] Add 1g / L of boric acid to 20℃ deionized water and stir to dissolve, adjust the solution temperature to 20℃, then add 2g / L nickel chloride, 2g / L nickel sulfate hexahydrate, 2g / L lemon Trisodium acid, 1g / L sodium chloride, stir and dissolve in turn, then add 1ml / L dispersant A, stir well, use 20HZ ultrasonic vibration for 1min, then adjust the solution with 3% sodium hydroxide After the pH value reaches 4, the electroplating solution can be obtained by constant volume;

[0027] Electroless plating of 200g diamond powder to obtain electroless plating sand, the quality of electroless plating sand is 1.05 times the quality of diamond micropowder, the electroless plating sand is drained and transferred to a barrel plating bottle, and 0.8L of the above electroplating solution is added To the scale line of the barrel plating bottle, install the barrel plating machine, turn on the pow...

Embodiment 2

[0030] The method for improving the coating quality of diamond wire includes the following steps:

[0031] Add 100g / L boric acid to 100°C deionized water and stir until it dissolves, adjust the solution temperature to 60°C, and then add 90g / L nickel chloride, 200g / L nickel sulfate hexahydrate, and 200g / L lemon. Trisodium acid, 150g / L sodium chloride, stir and dissolve in turn, then add 50ml / L dispersant A, stir well, use 40HZ ultrasonic vibration for 20min, then adjust the solution with 20% sodium hydroxide After the pH value reaches 8, the electroplating solution can be used at a fixed volume;

[0032] Electroless plating of 1000g diamond micropowder to obtain electroless plating sand, the quality of the electroless plating sand is 1.3 times the quality of the diamond micropowder, the electroless plating sand is drained and transferred to a barrel plating bottle, and 1.8L of the above electroplating solution is added To the scale line of the barrel plating bottle, install the bar...

Embodiment 3

[0034] The method for improving the coating quality of diamond wire includes the following steps:

[0035] Add 50g / L boric acid to 50℃ deionized water and stir to dissolve, adjust the solution temperature to 55℃, then add 40g / L nickel chloride, 100g / L nickel sulfate hexahydrate, and 100g / L lemon in sequence Trisodium acid, 100g / L sodium chloride, stir and dissolve in sequence, then add 30ml / L dispersant A, stir well, use 30HZ ultrasonic vibration for 10min, then adjust the solution with 15% sodium hydroxide After the pH value reaches 7, the electroplating solution can be obtained by constant volume;

[0036] Electroless plating of 500g diamond powder is used to obtain chemical plating sand. The quality of the chemical plating sand is 1.2 times that of the diamond powder. After the chemical plating sand is drained of water, it is transferred to a barrel plating bottle, and 1L of the above electroplating solution is added to The scale line of the barrel plating bottle, install the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com