Step-type micro convex point structure and preparation method thereof

A micro-bump and step-type technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as short circuit between micro-bumps, larger diameter of micro-bumps, and easy collapse, so as to ensure The effect of processing control accuracy, reducing PCB size, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific drawings and embodiments.

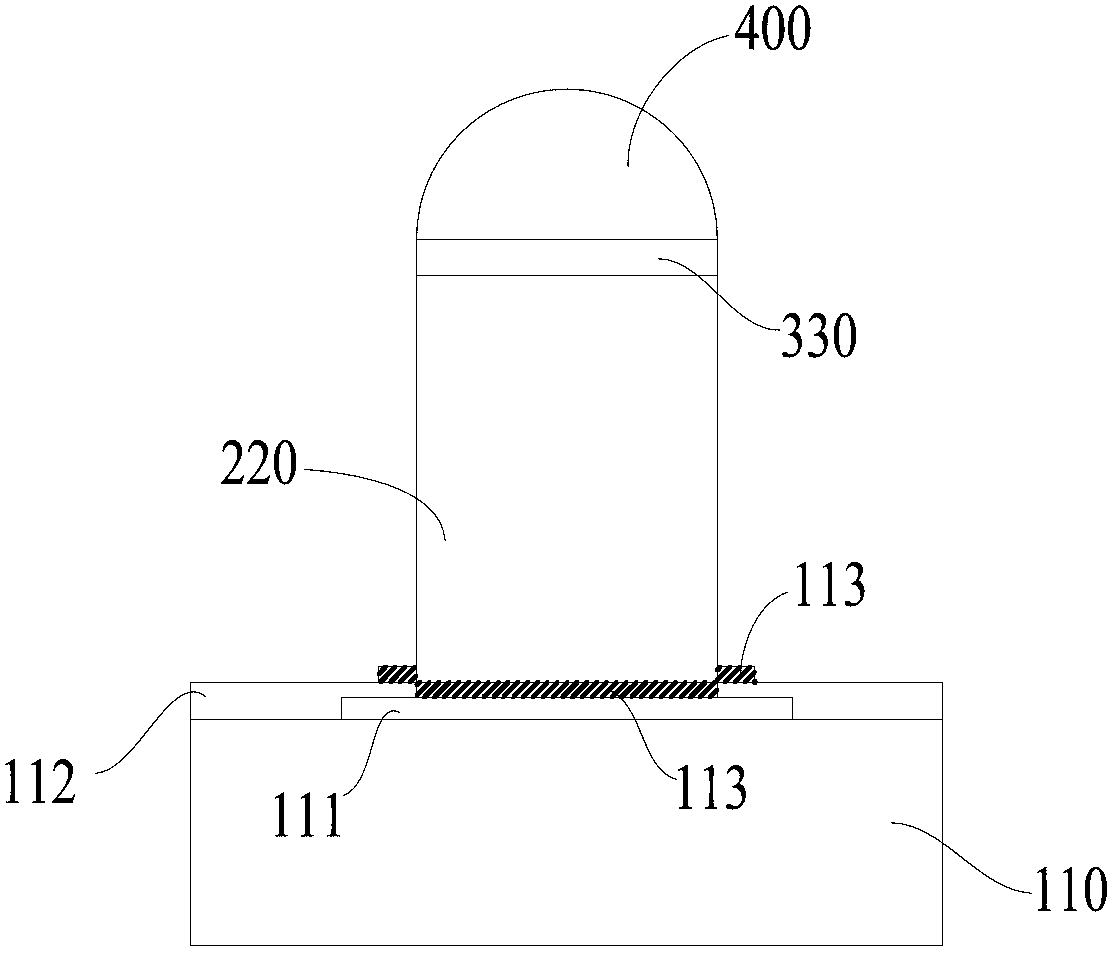

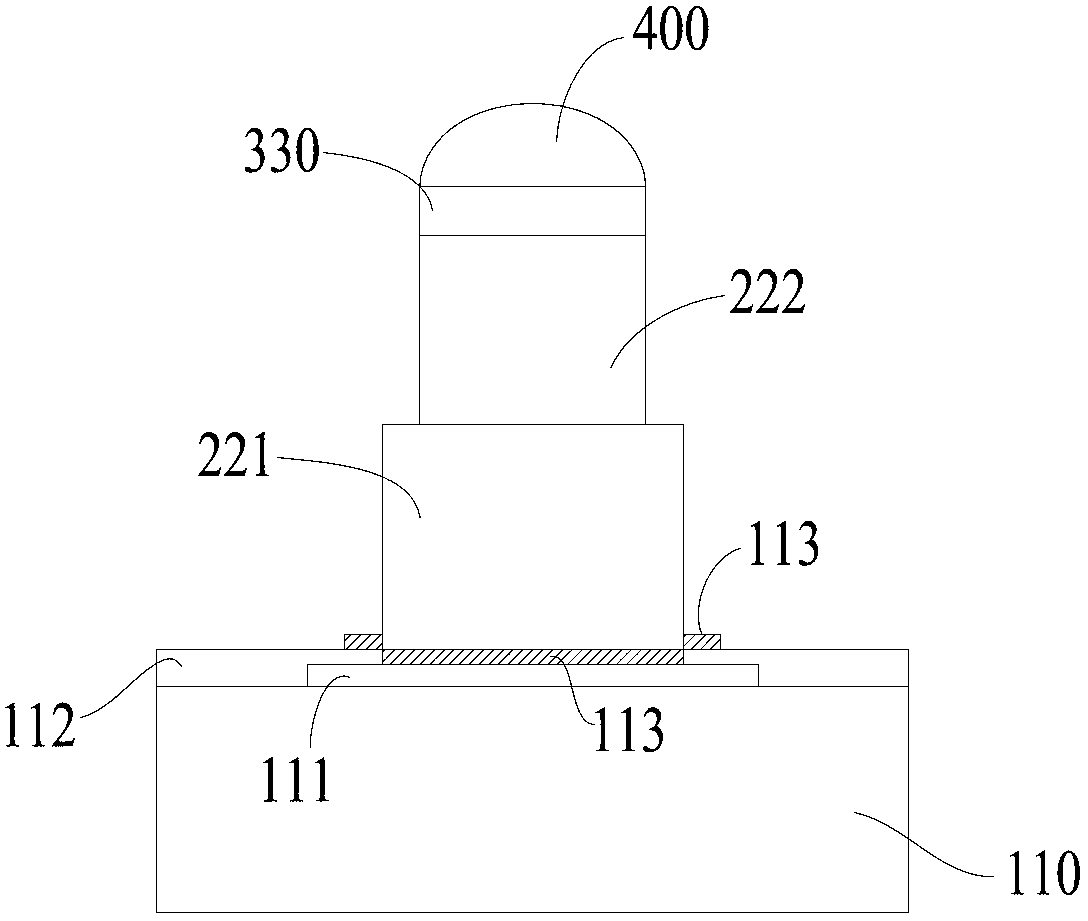

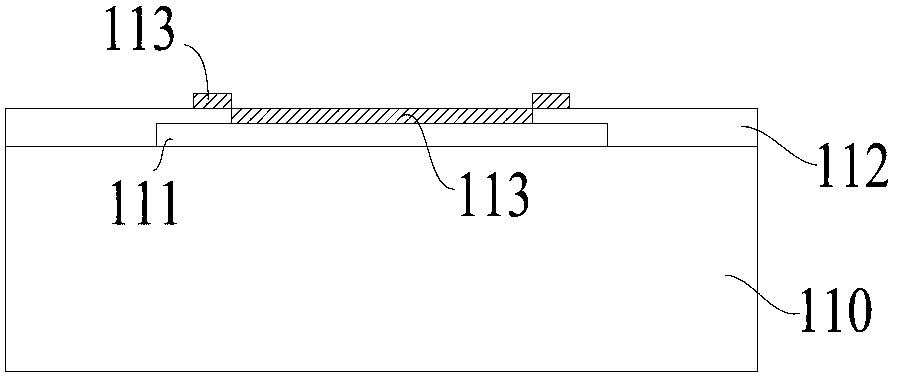

[0032] Such as figure 1 Shown: is the structure diagram of the existing micro-bump structure, the micro-bump structure includes a substrate body 110, a connection electrode layer 111 is arranged on one surface of the substrate body 110, and the connection electrode layer 111 covers the substrate body 110, and is electrically connected to the substrate body 110, the other side surface where the connection electrode layer 111 is connected to the substrate body 110 is covered with a passivation layer 112, and the connection electrode layer 111 and the substrate body 110 are protected by the passivation layer 112, The passivation layer 112 is etched to form an UBM layer 113 , and the UBM layer 113 passes through the passivation layer 112 and is electrically connected to the connecting electrode layer 111 . The UBM layer 113 is provided with a metal post 220, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com