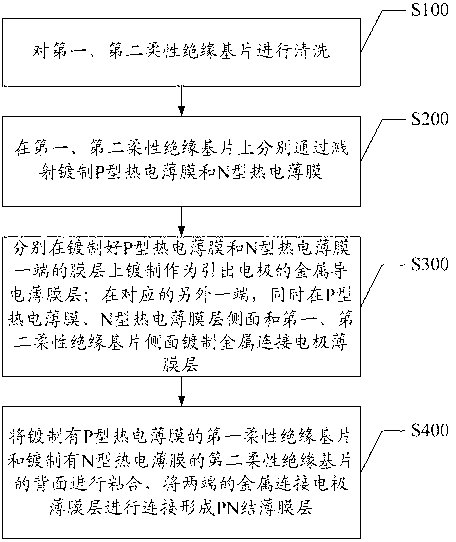

Flexible thin film thermobattery and manufacturing method thereof

A thermoelectric battery and flexible film technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems of high cost, low performance, low output power, etc., to reduce manufacturing costs, Lightweight, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

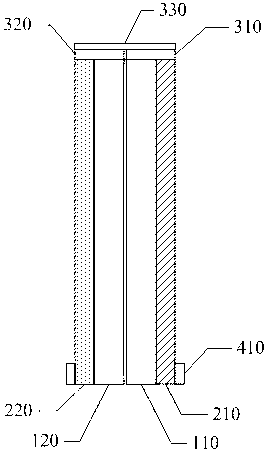

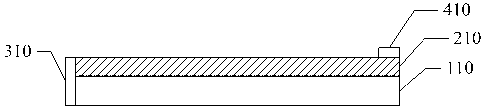

Embodiment 1

[0036] An ultra-high vacuum ion beam sputtering coating machine is used to prepare P-type and N-type thermoelectric thin film layers on the first and second flexible insulating substrates. The thermoelectric type is selected as P-type and N-type Sb 2 Te 3 and Bi 2 Te 3 The semiconductor compound is in the form of a composite target, and the Sb / Te and Bi / Te composite targets are respectively fixed on the target positions of the rotatable selective sputtering target. Choose flexible PI made of high-temperature polyimide as the first and second flexible insulating substrates, with a thickness of 0.15 mm, use alcohol and acetone to ultrasonically clean the first and second flexible insulating substrates, and then put them in the coating chamber on the fixture; respectively plate Sb on the first and second flexible insulating substrates 2 Te 3 and Bi 2 Te 3 Thin film layer with a thickness of 1 μm; then, by masking, on the thermoelectric film that has been plated, a metal co...

Embodiment 2

[0039] A multi-target magnetron sputtering sputtering coater is used to coat P-type and N-type thermoelectric thin films on the first and second flexible insulating substrates respectively. The thermoelectric type is selected as P-type and N-type Sb 2 Te 3 and Bi 2 Te 3 The semiconductor compound is in the form of magnetron co-sputtering. Sb and Bi high-purity targets are respectively placed on the DC sputtering target position of the multi-target magnetron sputtering coating machine, and Te is installed on the radio frequency target position. Choose flexible PI made of high-temperature polyimide as the insulating substrate, with a thickness of 0.15mm, use alcohol and acetone to ultrasonically clean the substrate, and then put it on the fixture in the coating chamber; Sb was plated on the substrate by magnetron co-sputtering technology 2 Te 3 and Bi 2 Te 3 Thin film layer with a thickness of 1 μm, and then by masking, on one end of the thermoelectric film that has been ...

Embodiment 3

[0042] An ultra-high vacuum ion beam sputtering coating machine is used to prepare P-type and N-type thermoelectric thin film layers on the first and second flexible insulating substrates. The thermoelectric type is selected as P-type and N-type Sb 2 Te 3 and Bi 2 Te 3 The semiconductor compound is in the form of a composite target, and the Sb / Te and Bi / Te composite targets are respectively fixed on the target positions of the rotatable selective sputtering target. Choose flexible PI made of high-temperature polyimide as the first and second flexible insulating substrates, with a thickness of 0.15 mm, use alcohol and acetone to ultrasonically clean the first and second flexible insulating substrates, and then put them in the coating chamber On the fixture; Sb is plated on the first and second flexible insulating substrates respectively 2 Te 3 and Bi 2 Te 3 Thin film layer with a thickness of 1 μm; then, by masking, on the thermoelectric film that has been plated, a meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com