Preparation method of seamlessly integrated metal substrate/nanoporous metal/metal oxide composite electrode material, and application of compound electrode material

A metal substrate, nanoporous technology, applied in hybrid capacitor electrodes, battery electrodes, circuits, etc., can solve problems such as capacity reduction, electronic conduction and ion diffusion obstacles, electrode failure, etc., to achieve accelerated kinetic characteristics and excellent electrochemical performance. , Excellent effect of larger size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The preparation process and steps in this embodiment are as follows:

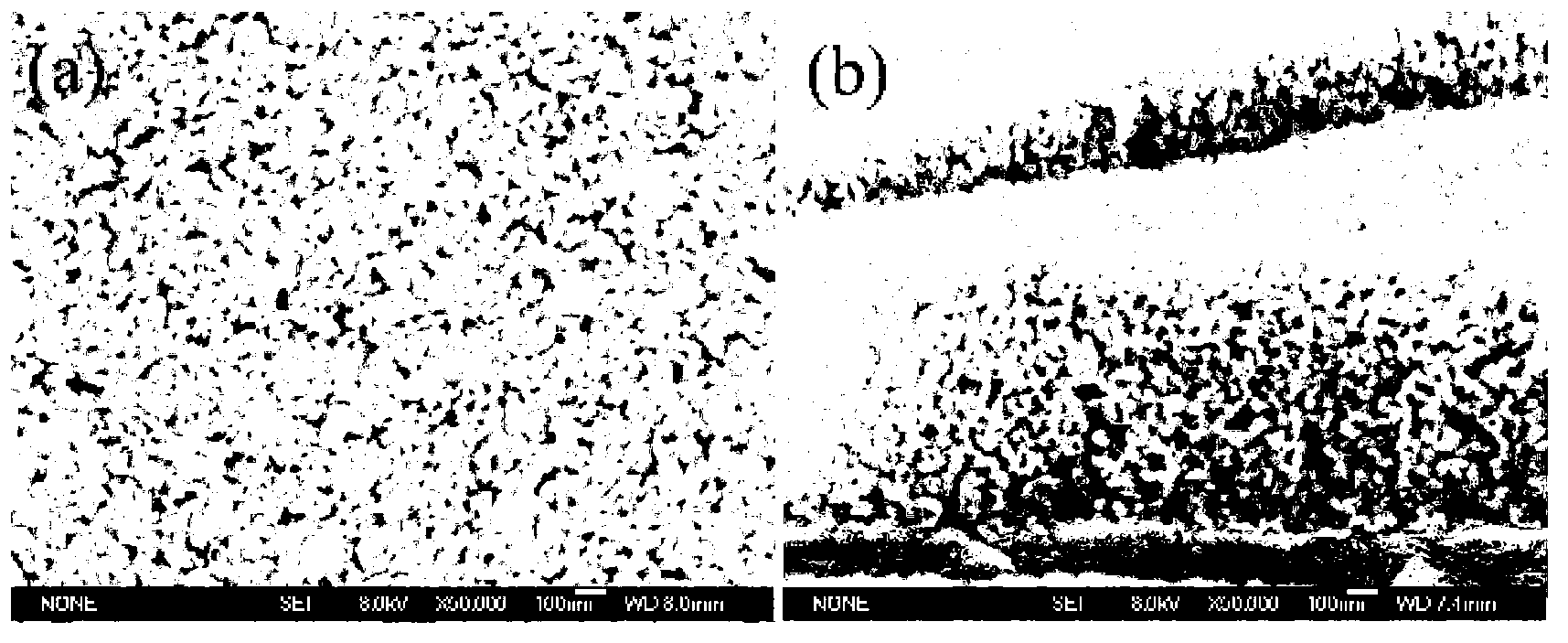

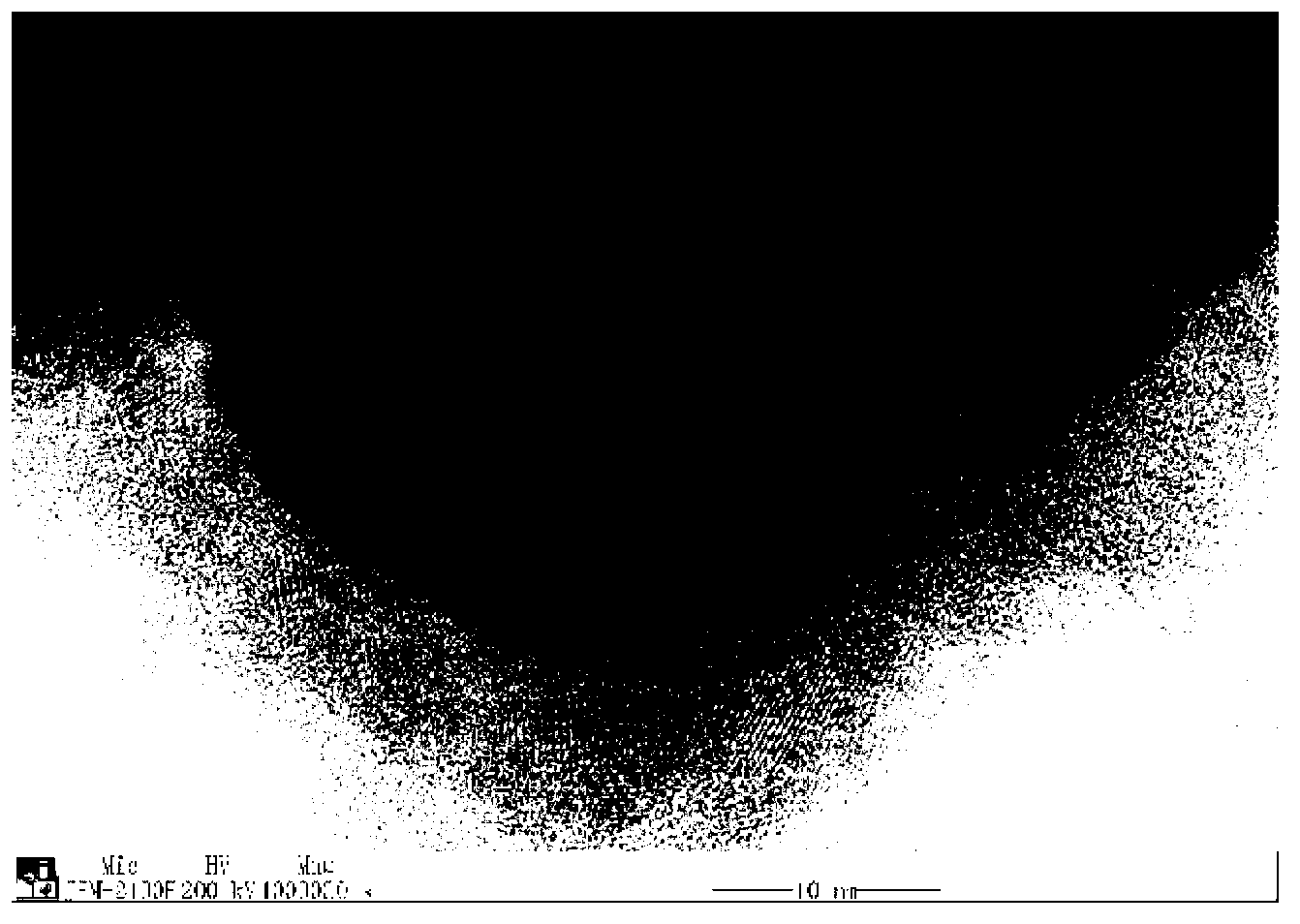

[0038] (1) A preparation method of a seamlessly integrated metal substrate / nanoporous copper electrode material: deposit Cu with a thickness of 800 nm on the substrate copper foil by magnetron sputtering at room temperature 30 mn 70 (Atomic ratio) alloy film, the size of copper foil is 3cm*2cm*15μm, the sputtering power is 200W, and the time is set for 20min; before the physical deposition of the base copper foil, it is sequentially deposited in 1M HCl solution and deionized water (18.6MΩ·cm) Wash thoroughly with ethanol. Then, at room temperature, the Cu 30 mn 70 The alloy film was chemically dealloyed in 10 mM HCl solution for 5 hours to obtain a copper substrate / nanoporous copper structure; finally, the residual acid in the nanoporous copper was removed by rinsing with deionized water.

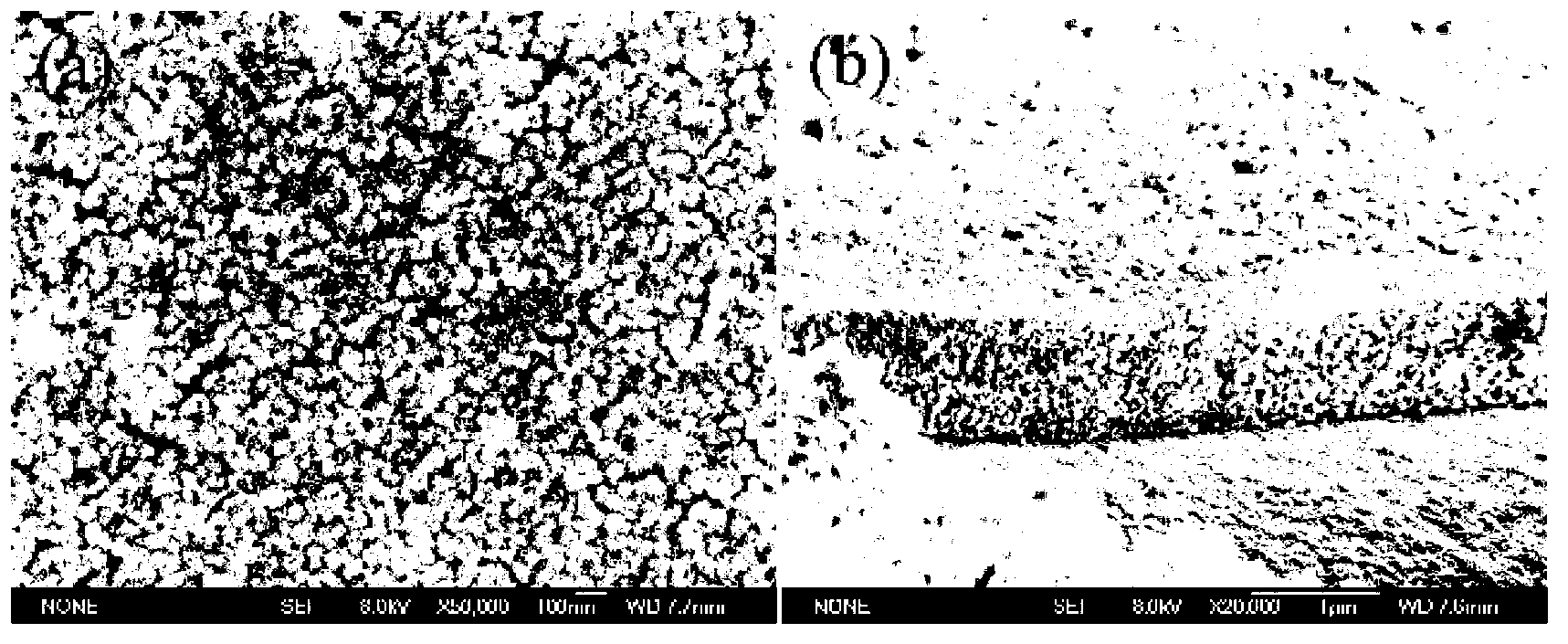

[0039] (2) Seamlessly integrated substrate / nanoporous copper / MnO 2 Preparation method of composite electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com