Preparation methods of sheep placenta polypeptide powder and soluble granules

A sheep placenta and polypeptide powder technology, which is applied in food preparation, protein food processing, animal protein processing and other directions, can solve the problems of insufficient development and utilization of sheep placenta, waste of resources, etc., to improve product flavor, reduce water absorption, Easy to absorb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

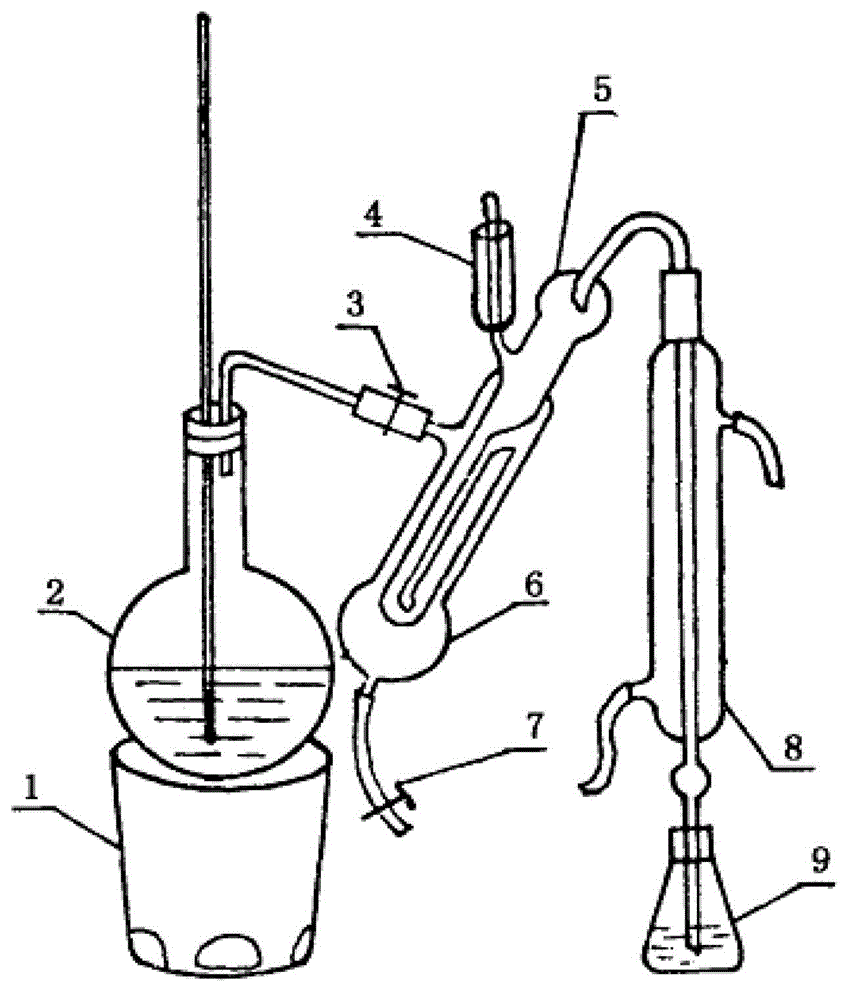

Image

Examples

preparation example Construction

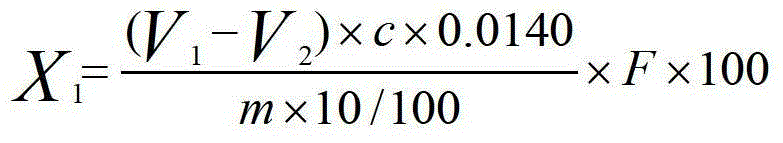

[0040] A kind of preparation method of sheep placenta polypeptide powder of the present invention is characterized in that, comprises the following stages

[0041] 1) Pretreatment of the sheep placenta raw material, tissue homogenization includes: selecting fresh sheep placenta as raw material, cleaning the fresh sheep placenta, removing impurities, draining, weighing, adding 0.5 to 1.0 times the weight of the fresh sheep placenta Pure water tissue homogenate;

[0042] 2) Enzyme hydrolysis, deodorization and debitterness, and enzyme inactivation, including the following steps:

[0043] (1) After heating the homogenate obtained in stage 1) at 90°C for 10-15 minutes, adjust the temperature to 50-55°C;

[0044] (2) Add 5-20ml of per 1kg of fresh sheep placenta The amount of protease and 1-5ml of flavor protease is added to the homogenate obtained in step (1) Protease and flavor protease, and control the temperature at 50-55°C, enzymolysis for 4 hours;

[0045] (3) Adjust the ...

Embodiment 1

[0163] 1) Raw material pretreatment of sheep placenta: select fresh sheep placenta as raw material, clean it, remove impurities, drain, weigh, add pure water 0.5 times the weight of sheep placenta for tissue homogenization.

[0164] 2) Enzymatic hydrolysis and deodorization and debitterness: heat the above homogenate at 90°C for 10 minutes, adjust the temperature to 50°C, and then add 5ml of per 1kg of fresh sheep placenta Protease and 1ml flavor protease, control the temperature at 50°C, and enzymatically hydrolyze for 4 hours. Then the temperature of the enzymolysis solution was adjusted to 30° C., and 1.0 g of active dry yeast powder was added to incubate for 60 minutes. Finally, the enzymolysis solution was heated at 90°C for 10 minutes to inactivate the enzyme.

[0165] 3) Centrifuge to remove impurities: Centrifuge the above enzymatic hydrolysis solution with a high-speed low-temperature centrifuge at 6,000 rpm for 10 minutes to remove water-insoluble matter to obtain ...

Embodiment 2

[0170] 1) Raw material pretreatment of sheep placenta: select fresh sheep placenta as raw material, clean it, remove impurities, drain, weigh, add pure water 1.0 times the weight of sheep placenta for tissue homogenization.

[0171] 2) Enzymatic hydrolysis and deodorization and debitterness: heat the above homogenate at 90°C for 15 minutes, adjust the temperature to 55°C, and then add 20ml of per 1kg of fresh sheep placenta Protease and 5ml flavor protease, control the temperature at 55°C, and enzymatically hydrolyze for 4 hours. Then the temperature of the enzymolysis solution was adjusted to 35° C., and 1.5 g of active dry yeast powder was added to incubate for 90 minutes. Finally, the enzymolysis solution was heated at 90°C for 10 minutes to inactivate the enzyme.

[0172] 3) Centrifuge to remove impurities: Centrifuge the above enzymatic hydrolysis solution with a high-speed low-temperature centrifuge at 6,000 rpm for 10 minutes to remove water-insoluble matter to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com