Enhanced sewage biological nitrogen and phosphorus removal method bases on polyhydroxyalkanoate metabolism regulation

A polyhydroxyalkanoate and sewage technology, applied in biological sludge treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of low carbon source concentration, difficult treatment of greenhouse gas primary and secondary sedimentation sludge and other issues, to achieve the effects of improving efficiency, easy large-scale promotion, and low cost of process transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

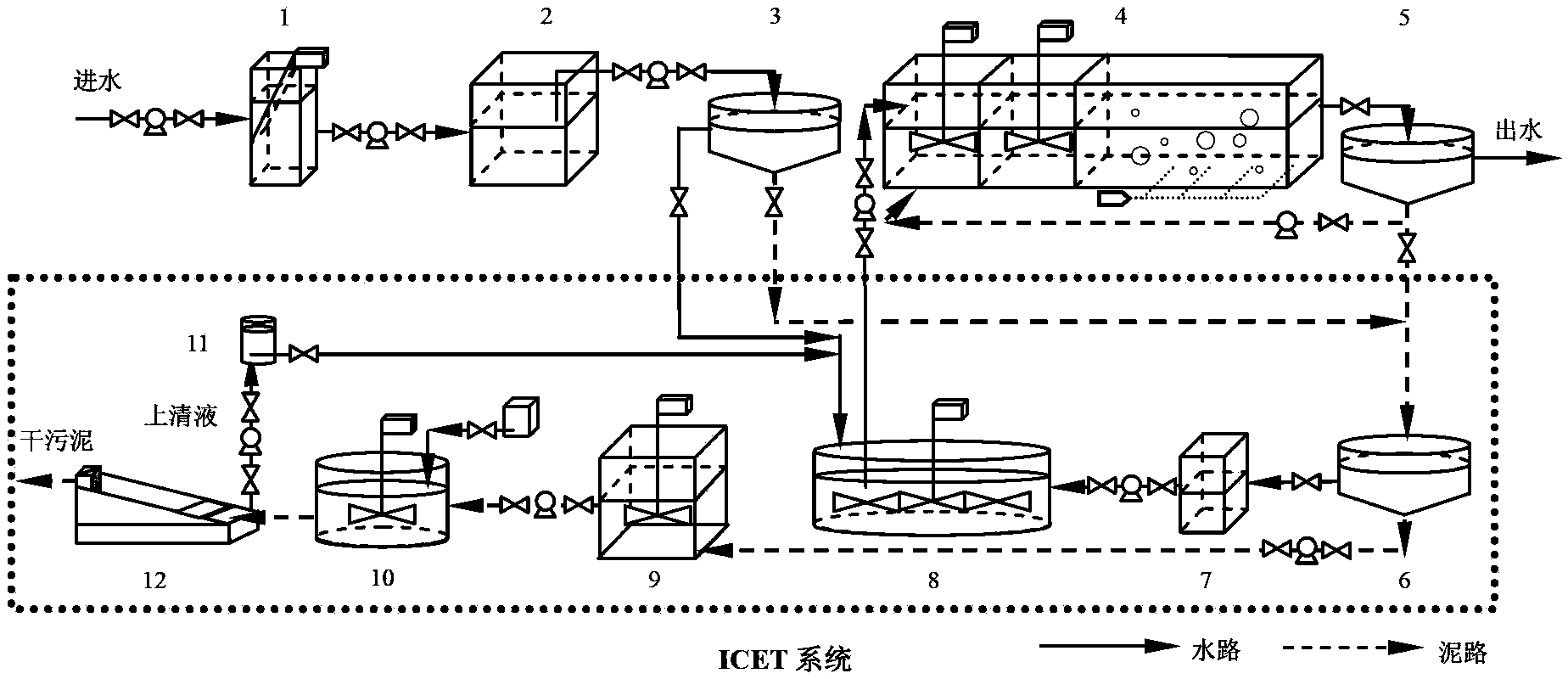

[0036] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge thickening tank 6 for concentration and sedimentation for 24 hours at a VSS ratio of 1:1;

[0037] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation for 8 days under the condition of controlling pH=10.0) and is directional converted into PHA precursor;

[0038] (3) The obtained PHA precursor (concentration is 4650mg COD / L, the contents of acetic acid and propionic acid are 48% and 41% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0039] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA prod...

Embodiment 2

[0042] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge concentration tank 6 for concentration and precipitation for 12 hours at a VSS ratio of 10:1;

[0043] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation under the condition of controlling pH=8.0 for 8 days);

[0044](3) The obtained PHA precursor (concentration is 4230mg COD / L, the contents of acetic acid and propionic acid are 56% and 28% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0045] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA production reactor 8 (control pH=6.8, react for 3....

Embodiment 3

[0047] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge concentration tank 6 for concentration and precipitation for 24 hours at a VSS ratio of 5:1;

[0048] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation under the condition of controlling pH=8 for 8 days);

[0049] (3) The obtained PHA precursor (concentration is 4310mg COD / L, the contents of acetic acid and propionic acid are 50% and 31% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0050] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA production reactor 8 (control pH=7.2, react for 3.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com