Antiflaming one-component modified silane polyether sealant and preparation method thereof

A silane-modified polyether, one-component technology, applied in the direction of polyether adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of single performance and few varieties, and achieve excellent flame retardancy and simple preparation methods , good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

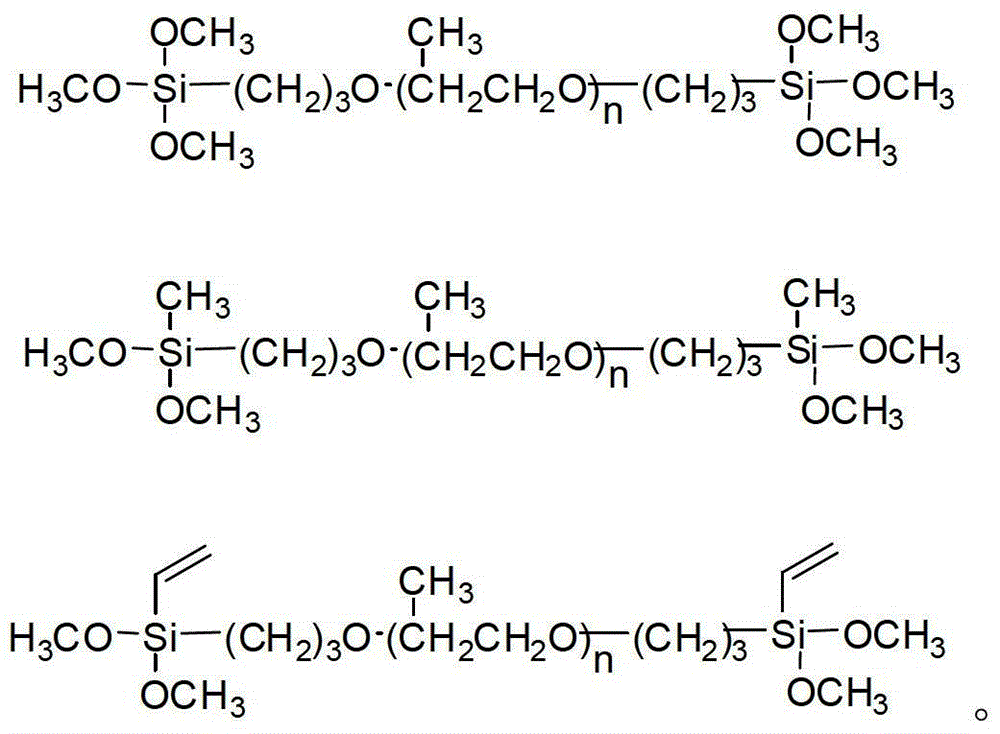

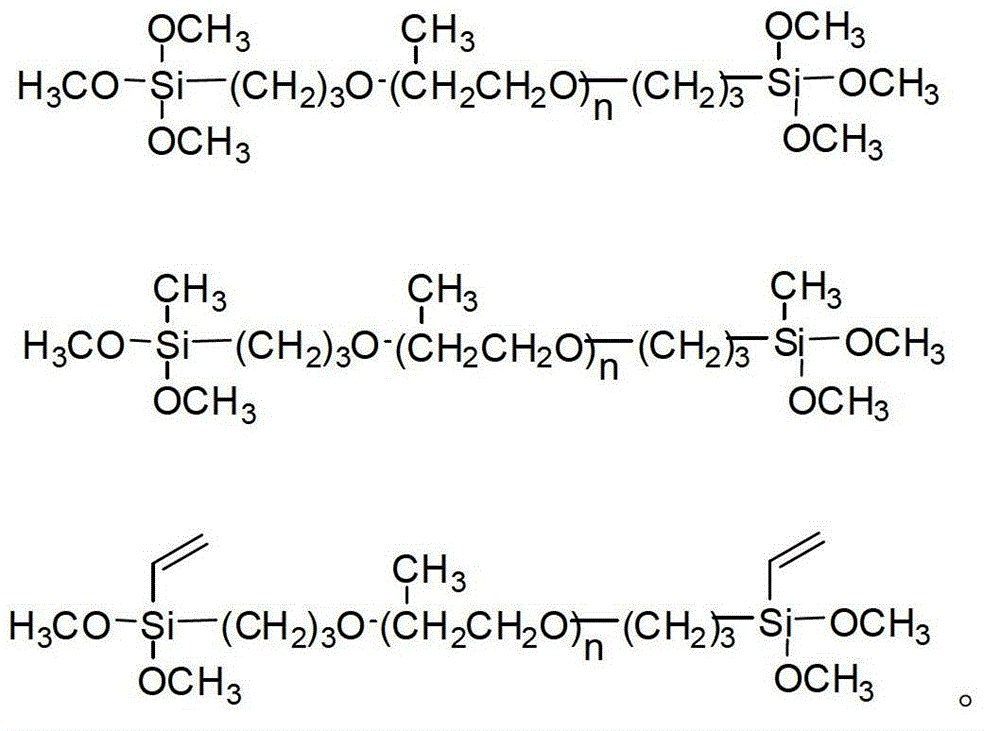

Method used

Image

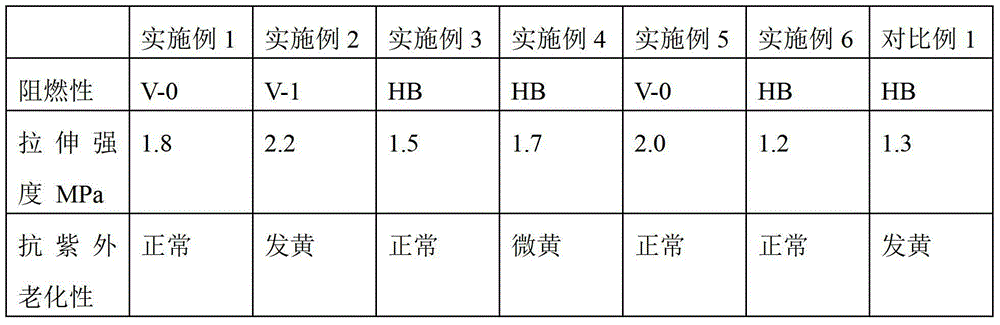

Examples

Embodiment 1

[0040] MS Premix:

[0041] 30g MS-polymer S203H

[0042] 10g didecyl phthalate

[0043] 30g aluminum hydroxide

[0044] 7.4g melamine cyanurate

[0046] 0.2g polyamide

[0047] 0.2 g CHISOR B234

[0048] 0.2g Tinuvin770

[0049] MS sealant:

[0050] 98.2g MS premix

[0051] 0.9g methyltriethoxysilane

[0052] 0.6g N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane

[0053] 0.3g dibutyltin dilaurate

Embodiment 2

[0055] MS Premix:

[0056] 27g MS-polymer S303H

[0057] 10.2g triphenyl phosphate

[0058] 30g aluminum hydroxide

[0059] 10g magnesium hydroxide

[0061] 0.3g polyamide

[0062] 0.25g CHISORB BP-12

[0063] 0.25g CHISOR B1278

[0064] MS sealant:

[0065] 98.2g MS premix

[0066] 0.8g methyltrimethoxysilane

[0067] 0.6g γ-aminopropyltrimethoxysilane

[0068] 0.4g dioctyltin diacetate

Embodiment 3

[0070] MS Premix:

[0071] 40g MS-polymer S203H

[0072]10g dioctyl phthalate

[0073] 30g aluminum hydroxide

[0076] 0.2g polyamide

[0077] 0.2 g CHISOR B234

[0078] 0.2g Tinuvin770

[0079] MS sealant:

[0080] 98.3g MS premix

[0081] 0.6g Vinyltrimethoxysilane

[0082] 0.6g N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane

[0083] 0.2g γ-glycidyl etheroxypropyltrimethoxysilane

[0084] 0.3g stannous octoate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com