Tuned mass damper with frame

A technology for tuning mass and shock absorbers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of building structure processing errors and design changes, which are not suitable for controlling high-frequency vibration and elasticity Solving problems such as a single variety of components, it achieves the effect of significant vibration reduction, no impact on appearance, and little impact on appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

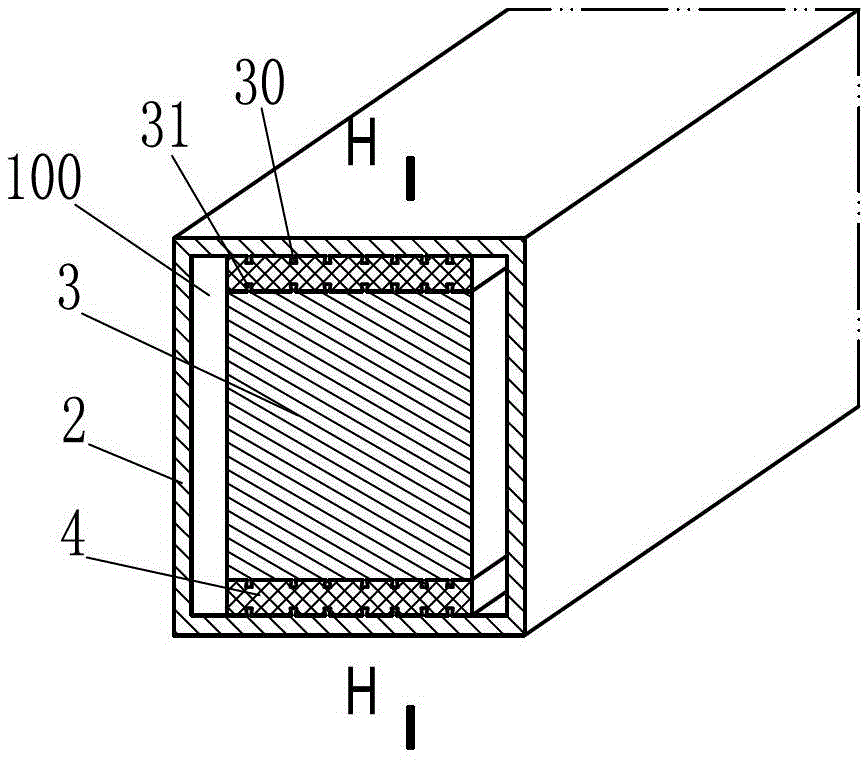

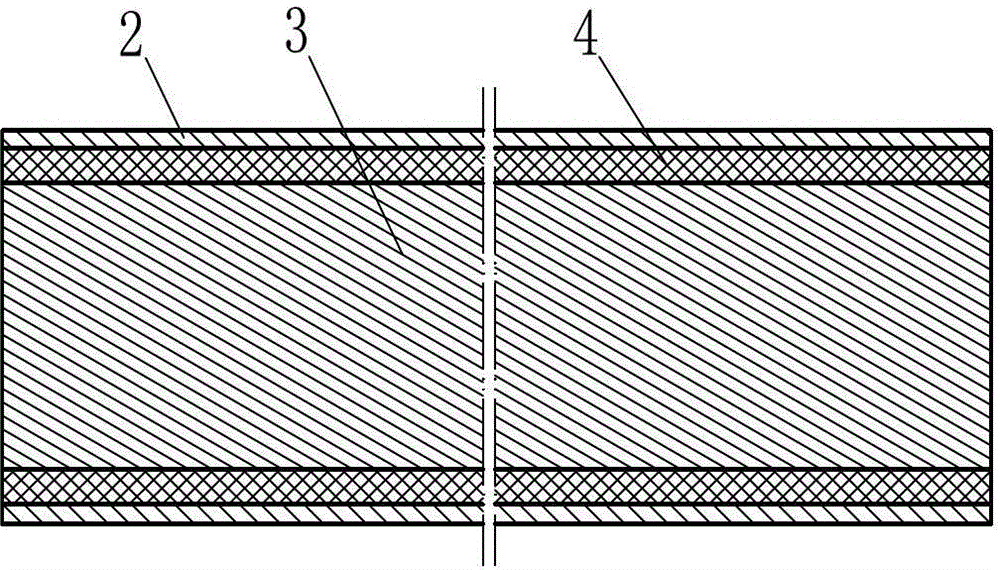

[0049] like figure 1 and figure 2 The tuned mass damper with a frame of the present invention shown in the present invention includes an elastic element 4 and a mass block 3, and also includes a coupling frame 2, which contains a vibration-absorbing cavity 100, and the mass block 3 is arranged on the vibration-absorbing cavity of the coupling frame 2. In the cavity 100 , an elastic element 4 is provided between the mass block 3 and the cavity wall of the vibration-absorbing cavity 100 . Specifically, the elastic element 4 is arranged between the upper and lower surfaces of the mass block 3 and the wall of the vibration-absorbing cavity 100, the coupling frame 2 is made of aluminum alloy material, and the elastic element 4 is made of rubber material, because the rubber material has good damping properties , is a commonly used elastic solid damping material, so the elastic element 4 is also a damping element at the same time, and the mass block 3 is an iron block, wherein the ...

Embodiment 2

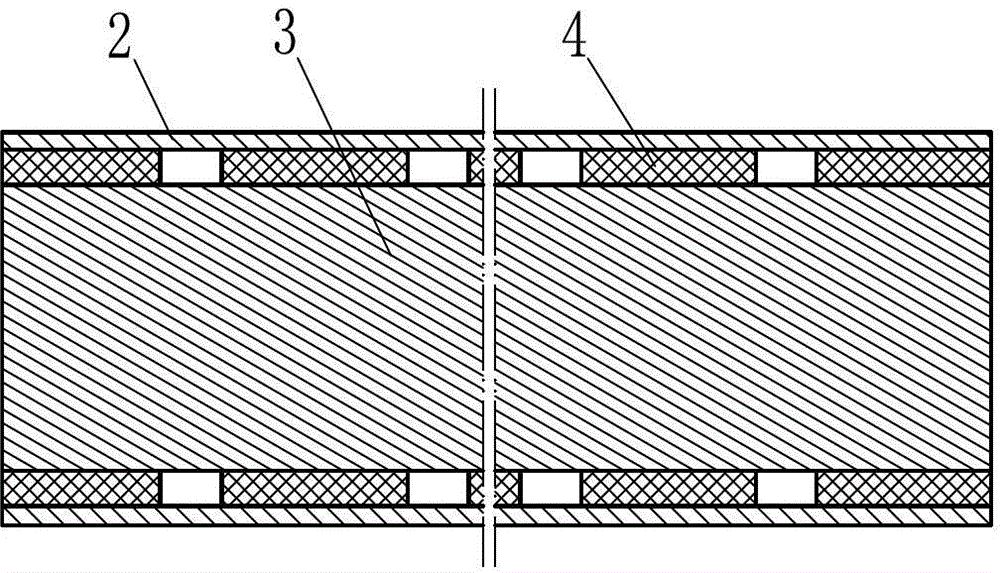

[0062] like Figure 4 The difference between the tuned mass damper with a frame of the present invention and the first embodiment is that the elastic element 4 is arranged between the left and right sides of the mass block 3 and the wall surface of the vibration-absorbing cavity 100, and the connecting frame 2 is made of glass fiber reinforced plastic. , the elastic element 4 is made of high-damping elastic polyurethane material, and the mass block 3 is made of steel material, wherein the elastic element 4 is fixedly connected with the mass block 3 and the wall of the vibration-absorbing cavity 100 through a chemical bonding process. In order to increase the reliability of the connection between the elastic element, the coupling frame and the mass block, a connection strengthening structure is respectively provided on the mating surface of the coupling frame and the elastic element and the mating surface of the mass block and the elastic element. The connection strengthening st...

Embodiment 3

[0066] like Figure 5The difference between the tuned mass damper with a frame of the present invention and the first embodiment is that the coupling frame 2 is made of steel, and the elastic element 4 adopts a metal spring, which is specifically a spiral steel spring in this example. The two ends are respectively welded and fixed on the connection frame 2 and the mass block 3 . In addition, in order to ensure that the elastic element 4 always forms an effective support for the mass block 3 during use, the elastic element 4 is pre-compressed when it is assembled with the mass block 3 and the coupling frame 2, and is in a pre-compressed state, and the elastic element 4 The pre-compression displacement is greater than the vibration amplitude of the mass block 3 relative to the wall of the vibration-absorbing cavity 100 when it is working.

[0067] The technical solution described in this example is the same as the application method in Example 1, and will not be repeated here. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com